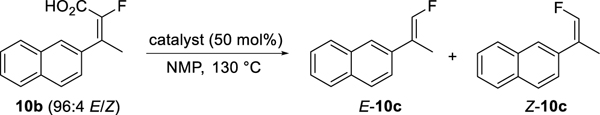

Table 4.

Decarboxylation catalyst screen.

| |||||

|---|---|---|---|---|---|

| entry | catalyst | Conversion (%)a | E/Zb | ||

| 1 h | 4 h | 24 h | |||

| 1 | Cu2O | - | 28 | 100 | 94:6 |

| 2 | CuO | - | 0 | 1 | 87:13 |

| 3 | Cu(OAc)2 | - | 1 | 45 | 94:6 |

| 4 | CuOAc | - | 0 | 0 | - |

| 5 | CuTCc | - | 5 | 50 | 95:5 |

| 6 | AgOTs | - | 8 | 21 | 96:4 |

| 7 | AgBF4 | - | - | 25 | 96:4 |

| 8 | AgOTf | 5 | - | 27 | 96:4 |

| 9 | AgNO3 | 100d | - | - | 76:24 |

| 10 | Ag2CO3 | 100d | - | - | 95:5 |

| 11 | Ag2O | 100d | - | - | 94:6 |

| 12 | AgOAc | 100 d | - | - | 96:4 |

| 13 | Pd(OAc)2 | - | 0 | 0 | - |

| 14 | Fe(acac)3 | - | 0 | 0 | - |

| 15 | [Ir(cod)Cl]2 | - | 0 | 0 | - |

| 16 | Rh(nbd)2BF4 | - | 15 | 55 | 99:1 |

| 17 | Rh(PPh3)3Cl | - | 0 | 0 | - |

Conversion of 10b to 10c as measured by HPLC (220 nm).

E/Z ratio from HPLC.

Copper(I) thiophene-2-carboxylate.

Conversion after 1.5 h.