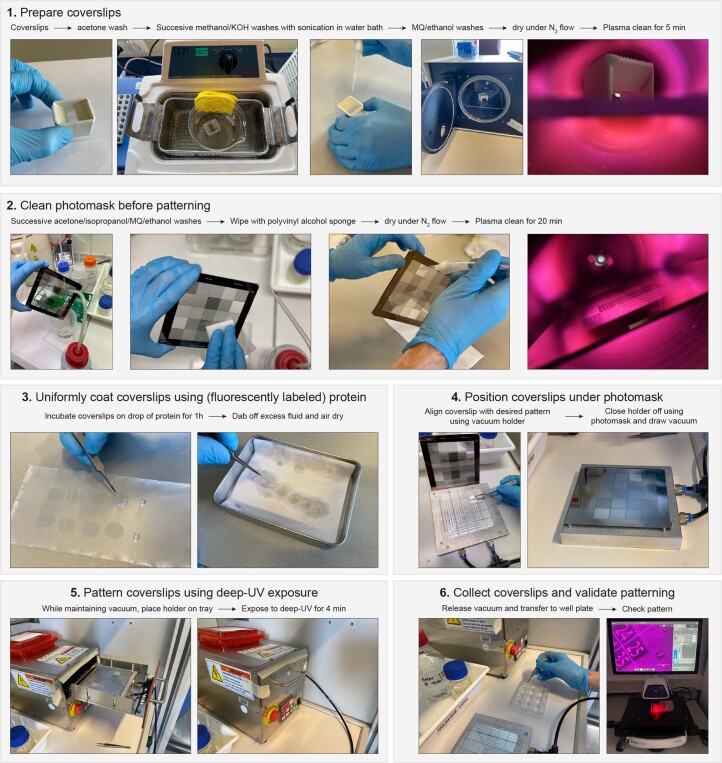

Extended Data Fig. 2. Graphical workflow for the production of GelMap coverslips.

1) Coverslips are thoroughly cleaned by first washing in acetone, and then successive methanol/potassium hydroxide washes with sonication. After rinsing in MQ and ethanol, coverslips are dried, and plasma cleaned. 2) Photomasks are thoroughly cleaned by first washing in acetone, then isopropanol alcohol, while wiping with a PVA sponge. After rinsing in MQ and ethanol, photomasks are dried, and plasma cleaned. 3) Cleaned coverslips are coated by incubating on a drop of pre-conjugated fluorescent protein for 1 hour, before air drying for long-term storage at room temperature. 4) Coated coverslips are placed on a vacuum holder to ensure positioning of the photomask directly above the coverslips. 5) The coverslips are exposed to deep-UV ( ~ 250 nm) through the photomask for 4 mins. 6) Patterned coverslips can be stored dry at room temperature, and the patterning efficiency can be immediately checked with a fluorescent microscope.