Abstract

Due to environmental concerns and budgetary constraints associated with synthetic fibers, natural fibers (NFr) are becoming increasingly popular as reinforcement in polymer composites (PCs) for structural components and construction materials. The surface treatment (ST) method is a well-established technique for enhancing the strength of interfacial bonding between NFr and the polymer matrix (PM). As a result, this research aims to determine the effect of ST with zinc oxide nanoparticles (ZnONPs) on the flexural properties of unsaturated polyester (UPE)/kenaf fiber (KF) nanocomposites. The hand lay-up technique was employed to produce KF-reinforced unsaturated polyester composites (KF/UPE) for this investigation. UPE/KF-ZnONPs composites were made with varying NFr loadings (weight percent), ranging from 10 to 40%. KF was treated with five distinct amounts of ZnONPs (from 1 to 5% weight percent). According to the findings of the investigation, the composite samples incorporating ZnONPs displayed superior optimum flexural properties compared to the untreated KF composite. It was found that 2% ZnONPs was optimal, and ST with ZnONPs could produce robust KF with improved flexural properties.

Keywords: Natural fiber, Nanohybrid, Surface enhancement, Nanomaterial

1. Introduction

The use of natural fibers (NFr) as an environmentally sustainable alternative to synthetic fibre in fibre-reinforced polymer composites (PCs) has garnered a lot of attention and been the focus of a number of studies. When compared to synthetic fibres made in a factory, NFr has several advantages, as it is cheaper, has a lower density, has comparable specific tensile characteristics, not abrasive to machinery, does not irritate the skin, uses less energy, poses less of a risk to human health, is renewable, recyclable, and biodegradable [[1], [2], [3]]. Kenaf bast fibre is one of the NFr that is getting attention in the fibre-reinforced polymer composites industries as a result of the favourable aspect ratios and high specific properties that it possesses at an affordable price [4,5]. In contrast to other natural fibre resources such as cotton, sisal, jute, and pineapple, kenaf bast fibre has demonstrated superior mechanical characteristics, including an elastic modulus that is equivalent to that of jute fibre [6]. The problem statement in this paragraph is that, while natural fibers like kenaf bast fiber have many benefits and are gaining attention in the fiber-reinforced Polymer Composites industries, they are not strongly compatible with the hydrophobic Polymer Matrix (PM). This incompatibility results in insufficient Interfacial Bonding (IB) between the natural fibers and the polymer matrix, leading to poor performance and a shorter lifespan of kenaf-reinforced composites [7,8]. The major challenge to be addressed, therefore, is finding an effective strategy for chemically modifying the natural fibers to improve the fiber-matrix interfacial bonding, thereby enhancing the performance and longevity of these composites.

The alkaline treatment or mercerization of kenaf bast fiber, accomplished through the utilization of sodium hydroxide (NaOH), is the most typical approach to modifying this type of fibre [[9], [10], [11]]. When treating the NFr, researchers tried out a variety of different immersion periods and NaOH solution concentrations [12,13]. Utilizing coupling substance is yet another well-liked strategy for the modification of kenaf bast fibre. The coupling agent is responsible for two different reactions: fthe first one is a reaction with the hydroxyl (OH) groups of the NFr, and simultaneously the second one is a reaction with the functional groups of the PM [14]. Both reactions are necessary for the coupling agent to execute its role. Fig. 1 demonstrates the mechanism of the compatibilizing agent that bridges the gap between the hydrophilic NFr and the hydrophobic PM. Both of these reactions are directed towards the end objective of facilitating the transfer of stress from the PM to the NFr. Because of the transformation, there are typically two different kinds of interactions that take place at the interfacial region. These interactions are known as primary and secondary bondings. The covalent and hydrogen bonds are examples of the primary and secondary types of bonds, respectively [15]. The circumstances of the treatment, such as the concentration of the chemical materials and the amount of time spent in ST, have a significant impact on the efficacy of such a modification [16]. The objective of the study to illustrate the effectiveness of nanoparticle surface treatment in enhancing the durability of natural fibre polymer composites. By increasing flexural strength, this method improves the overall resistance and robustness of these composites. The research addresses current knowledge gaps on how nanoparticle treatment affects the physical structure of natural fibres [17].

Fig. 1.

The mechanism of the compatibilizing agent that makes the hydrophilic filler compatible with the hydrophobic polymer matrix.

The novelty and significant advantages of using zinc oxide nanoparticle (ZnONPs) treatment for kenaf natural fiber lie in the unique properties of the ZnONPs, as well as the interaction between these particles and the KF as well as the polymer matrix [18]. Firstly, ZnONPs are known for their excellent mechanical and antimicrobial properties. When these nanoparticles are used in surface treatment, they can confer these properties to the KF, thereby improving the overall performance of the resulting composites [19]. This is especially beneficial for applications that require robust, durable materials with resistance to microbial attack. Furthermore, ZnONPs are small in size and have a high surface-to-volume ratio, which allows them to have a more intimate and effective interaction with the fiber surfaces [20]. This can lead to a superior level of interfacial bonding between the KF and the polymer matrix, thereby improving the flexural properties of the composite.

Compared to other treatment methods like alkali and silane treatments, ZnONPs treatment may provide a better balance between performance enhancement and environmental sustainability [21]. Unlike Alkali treatment, for instance, can enhance fiber-matrix adhesion by removing hemicellulose, lignin, and other impurities from the fiber surface, thereby increasing its surface roughness. However, it can also lead to fiber degradation and reduced flexural properties if not properly controlled. Silane treatment can improve the compatibility between hydrophilic fibers and hydrophobic polymer matrices by modifying the fiber surface with silane coupling agents [22]. However, this method can be relatively expensive due to the high cost of silane agents, and the effectiveness of the treatment can be affected by factors such as the type and concentration of the silane agent and the treatment conditions. Resin surface coatings can provide a protective layer on the fiber surface to reduce moisture absorption and improve the fiber-matrix interface [23,24]. Yet, they may increase the composite weight and cost, and their effect on the composite flexural properties can be variable. Our study on treating kenaf fibres with ZnONPs gives various reasonable benefits in comparison. In the beginning, ZnONPs may provide the fibres strong mechanical qualities, enhancing the performance of the final composites [25]. Second, ZnONPs may provide a higher degree of interfacial bonding between the fibre and the polymer matrix. Additionally, ZnONPs treatment is less harsh than alkali treatment, preserving the fiber integrity, and more cost-effective than silane treatment [26]. Furthermore, unlike resin coatings, ZnONPs can create a protective layer without substantially increasing the composite weight. Lastly, ZnONPs treatment offers a degree of control over the composite properties by adjusting the nanoparticle concentration [27]. In addition, ZnONPs treatment of KF is a relatively unexplored area, thus providing ample opportunities for novel and exciting discoveries. The finding from our study, for instance, that a 2% ZnONPs treatment yields optimal flexural properties, is a fresh contribution to the literature that can inspire further research in this direction. The use of ZnONPs for the surface treatment of KF introduces a novel approach that is potentially more sustainable, cost-effective, and efficient in enhancing the flexural properties of the resulting composites [28].

In addition to the aforementioned properties, another advantage of ZnONPs treatment is their role in reducing water absorption. It's well-known that natural fibers such as kenaf fibers absorb moisture, which can result in swelling, increased weight, and reduced flexural properties of the composites [29]. However, the application of ZnONPs can create a protective layer on the fiber surface, which can effectively lower the water uptake and consequently enhance the dimensional stability of the composites. The interaction of ZnONPs with natural fibers can also lead to the creation of new functional groups on the fiber surface. These functional groups can promote the adhesion between the fiber and the polymer matrix, which in turn can enhance the load transfer efficiency and the overall flexural properties of the composites [30]. It is also worth noting that the ZnONPs treatment process is generally simple and straightforward, without requiring complicated apparatus or procedures. This feature could potentially make it more appealing for industrial applications compared to other treatments that may require more complex procedures or harsh conditions [31].

Additionally, the introduction of ZnONPs to the natural fibers adds another degree of control over the composite properties. By adjusting the concentration of ZnONPs used in the treatment, it is possible to fine-tune the characteristics of the resulting composites, which can allow the production of composites tailored to specific applications or requirements. Overall, while alkali and silane treatments have proven their effectiveness in certain aspects, ZnONPs treatment offers a range of novel advantages that make it a promising alternative or complementary treatment method in the field of natural fiber-reinforced polymer composites [32].

Utilizing nanoparticles in surface treatment (ST) is yet another method that can be utilized to get around the hydrophilic and underperforming nature of NFr-reinforced PCs [ 30,33,34]. According to Wang et al., NFr has the potential to be functionalized with improved characteristics, particularly with regard to its ability to resist water and durability against biodegradation through the inclusion of inorganic components into NFr and its PM composites [33]. Despite a plethora of written research on the impact of ST on NFr's water uptake, mechanical efficiency, and morphology, gaps in knowledge remain. This study is the first to show that nanoparticle surface treatment is an important first stage in protecting natural fibre polymer composites from premature and unwarranted deterioration [34]. This finding was made possible by the fact that this study was conducted. This is achieved by enhancing flexural properties, leading to the creation of natural fibre polymer compounds with excellent resistance to moisture and high strength characteristics [35]. In summary, while existing treatment methods have made significant contributions to the field, our ZnONPs treatment method introduces a novel approach with unique advantages [32]. This research gap was the main motivation for our study, and our findings will undoubtedly open new opportunities for further investigations and developments in the field.

2. Materials and methods

2.1. Materials

The kenaf was supplied in the shape of a mat by the National Kenaf and Tobacco Board (NKTB), which is located in Kelantan, Malaysia. Throughout the research, the unsaturated polyester Reversol P-9565 (UPE) resin was employed as the PM for the composites. Dr. Rahmatullah Sdn. Bhd., Bukit Mertajam, Malaysia supplied it. Methyl ethyl ketone peroxide (MEKP) was sold by Kaumjung Akzo. Sigma-Aldrich (M) Sdn. Bhd. (Kuala Lumpur, Malaysia) supplied rod-shaped ZnONPs.

2.2. Treatment with Nano-ZnO

For the scientific exploration undertaken herein, kenaf mat sections were precisely cut to dimensions of 20 × 20 × 0.3 cm (length, width, and thickness respectively), ensuring compatibility with subsequent treatment processes. Surface treatment of the kenaf fibers (KF) was performed using Zinc Oxide Nanoparticles (ZnONPs). Concentrations of ZnONPs suspended in distilled water were varied across several levels: 0, 1, 2, 3, 4, and 5 wt%, providing a comprehensive gradient for analysis. In order to maintain suspension stability—an essential factor for effective nanoparticle dispersion—a regulated mixing speed of up to 2500 rpm was employed, carried out under controlled room temperature conditions. Enhanced dispersion was achieved using a Ragogna mixer, capable of reaching speeds of up to 5000 rpm, thereby inhibiting nanoparticle sedimentation. Subsequently, the KF was swiftly submerged in a ZnONPs solution, maintained at a controlled temperature of 60 °C for a 1-h period. Moderate heating was applied during this stage, facilitating the opening of KF cavities and enabling the infiltration of ZnONPs into the KF cellular structure [28]. Following this, the treated KF samples were subjected to a drying process in a conventional oven, precisely calibrated at 80 °C overnight. This drying stage was sustained for an uninterrupted period of 24 h, ensuring optimal treatment outcomes. Lastly, ZnONPs in powder form were methodically mixed with distilled water in a series of distinct percentage concentrations, providing a broad scope for our analysis. The specific weight percentages utilized in these mixtures are detailed in Table 1.

Table 1.

Percentage of ZnONPs that used for treatment KF.

| ZnONPs (g/L) | ZnONPs (wt%) |

|---|---|

| 10 | 1 |

| 20 | 2 |

| 30 | 3 |

| 40 | 4 |

| 50 | 5 |

2.3. Preparation of the composite

The composite material was synthesized utilizing the hand lay-up technique and molded into a stainless-steel form of dimensions 200 x 200 × 5 mm. Both untreated and treated kenaf fiber (KF) layers were hot pressed using Geotech GTM-5000 Series Universal Testing Machine for 15 min at 100 °C and at 10 MPa pressure. Initially, the KF mat was appropriately positioned within the mold. Subsequently, Unsaturated polyester resin was mixed with 2 parts per hundred of resin (phr) of MEKP and stirred by using high dispersion impeller stirrer at 200 revolutions per minute (rpm) for 2 min. Employed in minimal quantities, MEKP functioned as a catalyst, instigating the cross-linking of UP resin during composite fabrication. The proportions of KF, UPE, and MEKP involved in this process have been tabulated and are presented in Table 2. Upon completion of these steps, a blend of UPE resin and MEKP was distributed over the KF mat. A manual roller facilitated the even spread and impregnation of the resin throughout the mat. Four distinct KF loadings, in weight percentages of 10, 20, 30, and 40, were prepared for both treated and untreated KF. The impregnated fiber mats in the mold were covered with PET film on top and bottom before being flanked by stainless steel sheets on both sides. The molding was then pressed without heat using Gotech Testing Machine at 10 MPa for 5 min and left to be cured at room temperature for 24 h, as delineated in Fig. 2. Following compression, the molded material was allowed a curing period of 24 h at room temperature. Final processing involved the partition of the resultant composites into test specimens, achieved through the use of an electric saw. The resulting specimens adhered to dimensions of 20 × 20 × 0.3 cm.

Table 2.

Percentages of KF, UPE, and MEKP that used in the manufacturing the composites.

| Kenaf (%) | UP (%) | MEKP (%) |

|---|---|---|

| 10 | 88.2 | 1.8 |

| 20 | 78.4 | 1.6 |

| 30 | 68.6 | 1.4 |

| 40 | 58.8 | 1.2 |

Fig. 2.

Fabrication of UPE/KF polymer composites.

3. Testing and characterization

3.1. Flexural test

The flexural test was performed utilizing Instron Universal Testing Machine (Model 5569) equipped with a 1 KN loading of the cell. The crosshead speed was constant at 1 mm/min, while the size of the sample was 2.5 × 20 × 0.3 cm to obtain the flexural properties. The flexural strength and modulus were determined using a three-point bending test method according to D7264 test method. The load was placed on the midway of the sample between the supports of the testing machine. Each composite underwent five separate tests, with the average of those results being reported.

3.2. Scanning electron microscopy (SEM)

Using a JEOL JFC6460LA, the surface morphology of the flexural fractured samples of the prepared UPE/KF and UPE/KF-ZnONPs composites was examined. Before the test, the specimens were coated with a layer of platinum.

4. Results and discussion

4.1. Influence concentrations of zinc oxide nanoparticles (ZnONPs) on the flexural strength

The impact of changing the concentration of ZnONPs on the flexural strength of UPE/KF composites is shown in Fig. 3. As was demonstrated, treated KF-reinforced composites consistently performed better than untreated KF-reinforced composites after treatment with 1% and 2% ZnONPs. This was the case across all KF loadings as well. This finding can be understood by the superior interfacial adhesion of UPE-treated KF compared to untreated KF, as depicted in Fig. 4. IB between the NFr and PM enhances the stress convey between the NFr and PM, which enables composites to achieve their full potential in terms of strength [36]. The adhesion mechanism between zinc oxide nanoparticles on the fiber surface and unsaturated polyester involves several key factors. Firstly, it relies on the physical interactions between the nanoparticles and the polymer matrix [37]. The surface properties of both the nanoparticles and the unsaturated polyester play a crucial role in determining the extent of adhesion [38,39]. One contributing factor is the presence of functional groups on the surface of the nanoparticles and the polyester matrix. These functional groups, such as hydroxyl (-OH) and carboxyl (-COOH) groups, can form hydrogen bonds with each other, promoting adhesion. Additionally, the nanoscale size and high surface area of the zinc oxide nanoparticles provide a larger contact area with the polyester, facilitating better adhesion [40]. The nanoparticles can effectively penetrate the polymer matrix, creating interlocking structures that enhance the adhesion strength [41]. Furthermore, the chemical compatibility between the zinc oxide nanoparticles and the unsaturated polyester is important. Similar chemical compositions and structures can promote stronger adhesion by enabling better intermolecular interactions, such as van der Waals forces or covalent bonding [42,43]. However, after treatment with 3, 4, and 5% of ZnONPs concentration at each of the different KF loadings were evaluated, the flexural strength of the UPE/KF-ZnONPs composites decreased. This is due to the fact that nanocomposites that contain a more significant number of nanoparticles in total weight have reduced eventual compressive stress. The observed phenomena can be attributed to the inverse relationship between the concentration of nanoparticles in the nanocomposites and the resulting compressive stress. Specifically, an increase in the total weight percentage of nanoparticles within the nanocomposites corresponds to a reduction in the ultimate compressive stress. Simply put, as the amount of nanoparticles in the nanocomposites increases, the compressive stress these materials can withstand decreases. Because increasing the concentration of nanoparticles can lead to a phenomenon known as agglomeration, where the nanoparticles tend to cluster together rather than being evenly distributed throughout the composite material [44,45]. Agglomeration can cause localized areas of weakness in the composite, which can result in a reduction in the overall compressive stress the material can withstand [46]. Additionally, the interaction between the nanoparticles and the matrix material can also play a significant role. If the nanoparticles and matrix material do not bond well, it can lead to poor stress transfer from the matrix to the nanoparticles. This can also result in a decrease in the overall compressive strength of the composite material [47]. If the nanoparticle weight fraction is too high, this can lead to the formation of voids or cracks around the nanoparticles, which can weaken the overall composite and reduce the flexural strength, this phenomenon occurs due to several reasons.

-

•

Agglomeration: At high weight fractions, nanoparticles tend to agglomerate or cluster together. This clustering can result in poor dispersion throughout the polymer matrix. Uneven distribution of nanoparticles creates areas with higher nanoparticle concentrations, which can lead to localized stress concentration and void formation during processing or subsequent mechanical loading [48].

-

•

Insufficient polymer matrix: As the weight fraction of nanoparticles increases, the proportion of the polymer matrix decreases. The polymer matrix plays a vital role in providing mechanical strength and acting as a binder for the nanoparticles. If the polymer content becomes insufficient, it may not adequately encapsulate and support the nanoparticles, leaving them more vulnerable to stress-induced deformation and cracking [49].

-

•

Mismatch in thermal expansion: Nanoparticles and the polymer matrix often have different coefficients of thermal expansion. When subjected to temperature variations, the mismatch in thermal expansion between the nanoparticles and the surrounding polymer can generate significant internal stresses [50]. These stresses can lead to the formation of cracks or voids around the nanoparticles, particularly if the weight fraction is too high.

Fig. 3.

Flexural strength of the untreated UPE/KF composites and treated UPE/KF-ZnONPS composites.

Fig. 4.

SEM micrographs of UPE/KF-ZnONPs composite treated with 2% ZnONPs at 5000 × magnification.

Additionally, nanoparticles can also introduce new deformation mechanisms that are not present in the pure polymer matrix. For example, when a tensile force is applied to a composite with nanoparticles, the nanoparticles can slide or rotate within the polymer matrix, leading to plastic deformation [51,52]. This phenomenon occurs due to the strength of the interfacial bonding between the nanoparticles and the polymer matrix can vary depending on factors such as surface functionalization, compatibility, and processing conditions [53,54]. If the interfacial bonding is weak, the nanoparticles can experience relative motion within the matrix under applied stress. Furthermore, Polymers typically exhibit a certain degree of chain mobility, allowing them to undergo plastic deformation [55]. When stress is applied to the composite material, the polymer chains can rearrange and flow around the nanoparticles, facilitating their movement within the matrix [56]. Additionally, the size and shape of the nanoparticles also influence their ability to slide or rotate within the polymer matrix. Smaller nanoparticles or those with irregular shapes can easily fit between the polymer chains and move more freely, contributing to plastic deformation. External stress or mechanical loading on the composite material can induce deformation and create shear forces. These shear forces can cause the nanoparticles to slide or rotate, altering their positions within the polymer matrix. It is important to note that the extent of nanoparticle sliding or rotation depends on various factors such as interfacial bonding strength, nanoparticle concentration, applied stress, and temperature. Controlling these factors and optimizing the composite design can help achieve the desired balance between plastic deformation and material stability [57]. The incorporation of nanoparticles within a polymer matrix, while proven to enhance its flexural properties, can potentially attenuate the composite's flexural strength, predisposing it to premature failure under diminished stress levels [58]. Thus, it becomes imperative to meticulously optimize the weight fraction of nanoparticle integration to strike an appropriate equilibrium between the composite's strength and its other intrinsic properties, as corroborated by existing literature [59]. This optimization serves to elevate the composite's performance and utility in various applications.

Another factor that can affect the flexural strength of nanocomposites with a greater nanoparticle weight fraction is the aggregation or clustering of the nanoparticles [60]. As the concentration of nanoparticles increases, there is a greater chance for them to agglomerate or form clusters, which can lead to heterogeneity and reduced flexural properties [61,62]. When the concentration of nanoparticles in the nanocomposite rises above a certain threshold, the particles begin to agglomerate [63,64]. This acts as an obstacle to stress transmission from the PM to the NFr, which leads to a decline in flexural performance in composites that have a greater percentage of inorganic nanoparticles than 2% and Sharma et al. [65] noticed the similar effect. The results were in agreement with those found by Arshad et al. [66], who found that the tensile tension drops as the amount of nanoparticles in the sample rises. Furthermore, the size and shape of the nanoparticles can also impact the flexural strength of the composite. Larger nanoparticles can create larger defects in the PM, which can reduce the strength of the composite. Similarly, nanoparticles with irregular shapes can create stress concentrations and weaken the composite. However, the dilemma of inadequate IB between PM and NFr led to ineffective stress transfer between the PM and NFr, which diminished flexural strength value [67].

The methodological approach employed in the preparation of nanocomposites is unequivocally influential in determining their resultant flexural properties. For instance, inadequate amalgamation of nanoparticles and the polymer matrix throughout the processing stage can culminate in suboptimal dispersion and nanoparticle agglomeration [68,69]. These phenomena could potentially contribute to depreciation in flexural strength. In essence, while nanocomposites showcasing elevated nanoparticle weight fractions may exhibit amplified flexural properties, careful optimization of not only the specific weight fraction but also the size and morphology of the nanoparticles is required [70,71]. Additionally, rigorous attention must be devoted to the processing methodologies employed in order to forestall defect formation, thereby safeguarding optimal flexural performance. This optimization process is a critical consideration in the fabrication of nanocomposites, ensuring their functional viability in a broad spectrum of applications and maximizing the benefits derived from the incorporation of nanoparticles. The flexural strength of UPE/KF composites prior and upon treating the KF with varying amounts of ZnONPs is compared in Table 3. The table outlines the effects of varying ZnONP treatment concentrations and layer numbers on the flexural strength of the samples, as measured in MPa. The percentage increment and decrement in the flexural strength after treatment are also provided. In all cases, the samples demonstrate an increase in flexural strength when treated with ZnONPs at concentrations of 1% and 2%. For samples with one layer, the flexural strength increases by 5.1% and 11.1% when treated with 1% and 2% ZnONPs, respectively. Similarly, for the two-layer samples, there is an increase of 3.2% and 8.9% with 1% and 2% ZnONPs, respectively. For three-layer samples, the increments are 4.4% and 7.0%, while for the four-layer samples, these values are 5.2% and 8.8%. However, when the concentration of ZnONPs is increased to 3%, 4%, or 5%, there is a marked decrease in flexural strength across all sample categories. The one-layer samples show decrements of 5.7%, 9.8%, and 14.2% for 3%, 4%, and 5% ZnONPs respectively. The respective decrements for the two-layer samples are 3.4%, 10.9%, and 19.6%; for the three-layer samples, these figures are 4.8%, 10.0%, and 17.0%. Lastly, the four-layer samples show decreases of 4.3%, 8.9%, and 15.9% at the 3%, 4%, and 5% ZnONPs concentrations respectively.

Table 3.

Percentage difference in flexural strength prior to and following treatment with ZnONPs.

| Sample | Flexural strength (MPa) | Increment (%) | Decrement (%) |

|---|---|---|---|

| 1 layer prior and upon treating with 1% ZnONPs | 56/59 | 5.1% | – |

| 1 layer prior and upon treating with 2% ZnONPs | 56/63 | 11.1% | – |

| 1 layer prior and upon treating with 3% ZnONPs | 56/53 | – | 5.7% |

| 1 layer prior and upon treating with 4% ZnONPs | 56/51 | – | 9.8% |

| 1 layer prior and upon treating with 5% ZnONPs | 56/49 | – | 14.2% |

| 2 layer prior and upon treating with 1% ZnONPs | 61/63 | 3.2% | – |

| 2 layer prior and upon treating with 2% ZnONPs | 61/67 | 8.9% | – |

| 2 layer prior and upon treating with 3% ZnONPs | 61/59 | – | 3.4% |

| 2 layer prior and upon treating with 4% ZnONPs | 61/55 | – | 10.9% |

| 2 layer prior and upon treating with 5% ZnONPs | 61/51 | – | 19.6% |

| 3 layer prior and upon treating with 1% ZnONPs | 66/69 | 4.4% | – |

| 3 layer prior and upon treating with 2% ZnONPs | 66/71 | 7.0% | – |

| 3 layer prior and upon treating with 3% ZnONPs | 66/63 | – | 4.8% |

| 3 layer prior and upon treating with 4% ZnONPs | 66/60 | – | 10.0% |

| 3 layer prior and upon treating with 5% ZnONPs | 66/56 | – | 17.0% |

| 4 layer prior and upon treating with 1% ZnONPs | 73/77 | 5.2% | – |

| 4 layer prior and upon treating with 2% ZnONPs | 73/80 | 8.8% | – |

| 4 layer prior and upon treating with 3% ZnONPs | 73/70 | – | 4.3% |

| 4 layer prior and upon treating with 4% ZnONPs | 73/67 | – | 8.9% |

| 4 layer prior and upon treating with 5% ZnONPs | 73/63 | – | 15.9% |

This data reveals a trend where low ZnONP concentrations (1–2%) improve flexural strength, while higher concentrations (3–5%) reduce it. Furthermore, it is interesting to note that the rate of decrement in flexural strength tends to increase with the number of layers and ZnONPs concentration [72]. This indicates the necessity of a balanced approach when determining nanoparticle concentrations in composite materials. To delve deeper into the analysis, the data distinctly demonstrate a proportional relationship between the ZnONPs concentration and the flexural strength within the range of 1% and 2% ZnONPs. This enhancement in flexural strength is observed across all layers (one to four) suggesting that at these low ZnONPs concentrations, the nanoparticle treatment enhances the structural rigidity of the layers, thereby improving their resistance to bending or flexural forces [73]. However, beyond 2% concentration, this relationship is inversed and a significant decrement is observed, indicating the detrimental effect of excessive ZnONPs concentrations on the flexural strength of the samples. At these higher concentrations, the ZnONPs might induce aggregation or formation of defects within the composite, leading to a decrease in structural integrity and subsequently, a reduction in the flexural strength [74].

Interestingly, the extent of decrement is found to be more pronounced as the number of layers increases. This could be due to the potential for increased internal stresses or defects with increasing layer thickness or complexity, which are further amplified by the high concentrations of ZnONPs. Overall, this analysis underscores the critical importance of determining an optimal balance in the use of ZnONPs, taking into account the number of layers and concentration of nanoparticles. Achieving this balance is key to maximizing the potential benefits of nanocomposites in various applications while minimizing any potential negative impacts on their flexural properties [60]. When zinc oxide nanoparticles are added to a composite material, they can contribute to its mechanical reinforcement through several mechanisms.

-

•

Reinforcement Effect: On a fundamental level, the nanoparticles act as miniature reinforcements within the polymer matrix, much like the rebar in concrete. The inclusion of these nanoparticles can provide additional support and prevent crack propagation by impeding the movement of the polymer chains. When stress is applied to the material, the nanoparticles bear a portion of the load, resulting in an overall increase in the material's mechanical strength, including its flexural strength [75].

-

•

Improved Compatibility: Compatibility refers to the degree of interaction between the nanoparticles and the polymer matrix. A high degree of compatibility suggests a strong interaction between the two, which can result in a more homogeneous distribution of the nanoparticles within the matrix. This distribution can contribute to the overall strengthening effect by providing reinforcement throughout the material, rather than in localised areas [76].

-

•

Chemical Bonding: Zinc oxide nanoparticles can also induce chemical bonding with the polymer matrix. The nanoparticles' surface atoms can form covalent, ionic, or hydrogen bonds with the atoms of the polymer chains, depending on the nature of the polymer and the processing conditions. These bonds effectively "lock" the nanoparticles and polymer chains together, creating a composite material with enhanced mechanical properties [77].

-

•

Hindering Crack Propagation: Crack propagation, or the growth of cracks within a material under stress, is a significant factor that leads to mechanical failure. The presence of the dispersed nanoparticles can obstruct the path of a propagating crack, causing it to deviate or bifurcate. This process absorbs fracture energy, effectively slowing down or stopping further crack growth, and thereby enhancing the material's toughness and resistance to fracture [78].

The effect of zinc oxide nanoparticles on a polymer matrix can be complex, and it's likely that all these mechanisms - reinforcement, improved compatibility, chemical bonding, and hindering crack propagation - are at play to some degree when the mechanical properties of the composite are enhanced. However, it's important to note that the extent to which each mechanism contributes can depend on many factors, including the type of polymer, the size and concentration of the nanoparticles, and the processing conditions.

4.2. Impact kenaf fiber loadings on the flexural strength

Fig. 3 demonstrates that the flexural strength of untreated UPE/KF composites increases as KF loading increases [27,79]. This claim is in line with the general finding that flexural strength of PCs rises with rising KF loadings up to a specified loading prior it is reduced [28]. At 30% KF loading incorporation in this study, the flexural strength increased significantly because KF can react with the matrix to form a stronger bond between them [80]. This is known as a chemical strengthening effect. When KF is added to the matrix containing UPE, it reacts with it to form a layer at the grain boundaries. This layer acts as a glue, binding NFR and UPE together and making them more resistant to fracture. This interaction occurs due to the chemical composition of both the kenaf fiber and the matrix, enabling the formation of chemical bonds at the interface. The specific type of bonding between kenaf fiber and the matrix can vary depending on the matrix material used. In the case of thermosetting polymers, such as epoxy resins, the bonding between kenaf fiber and the matrix primarily involves covalent bonding [81]. During the curing process of thermosetting resins, the reactive groups present in the resin, such as epoxy groups, can react with functional groups on the surface of the kenaf fiber. This chemical reaction leads to the formation of covalent bonds between the fiber and the matrix, resulting in a strong and durable bond. Additionally, physical interactions, such as hydrogen bonding and van der Waals forces, may also contribute to the bonding between kenaf fiber and the matrix. These interactions can occur between functional groups on the fiber surface, such as hydroxyl (-OH) or carboxyl (-COOH) groups, and complementary groups in the matrix material. The amount of KF loading needed to achieve a significant increase in flexural strength relies on a number of different factors such as the type of matrix material, processing conditions, and the desired properties [82]. However, in general, higher KF loadings can lead to further improvements in strength, up to a certain point where diminishing returns are observed due to excessive incorporation of KF. The optimum loading of KF was 40 wt% which resulted in a marginal improvement in flexural strength. The flexural strength of the UPE/KF composites was significantly decreased when incremental loadings of KF at 45% loadings were applied [83,84]. The reason for this is that the amount of PM present is inadequate to effectively moisten the KF and achieve the desired results. Inferior levels of fibre saturation can result in a deficiency of IB strength. It was in line with what Salman and his colleagues discovered in their investigation [85], who determined that the composite with 40% KF loadings demonstrated the highest mechanical characteristics value prior to a decrease with increasing KF loadings. The PM was incapable of effectively wetting the KF at higher KF loadings (45 and 50%). This condition reduces the matrix's capacity to transmit the stress to the reinforcement fibre. Furthermore, factors such as fiber-matrix interaction, fiber orientation, and processing conditions can all affect the flexural properties of a composite material.

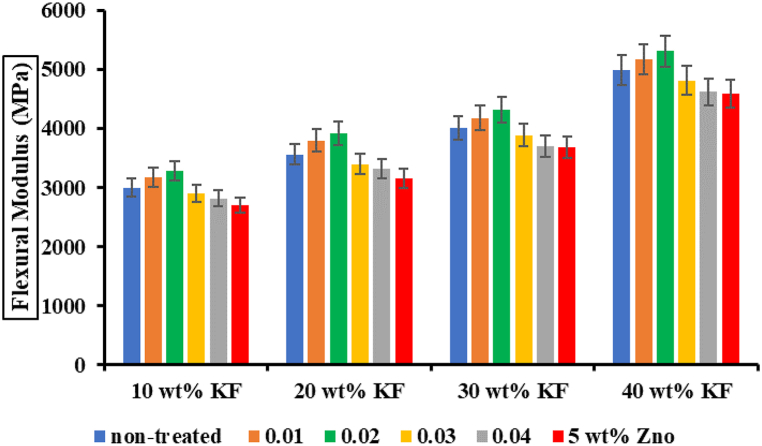

4.3. Influence concentrations of zinc oxide nanoparticles (ZnONPs) on the flexural modulus

Fig. 5 illustrates the impact of changing the proportion of ZnONPs on the flexural modulus of various KF loadings. It was found that treated KF composites have a greater flexural modulus at 2% ZnONPs in comparison to untreated KF composites. The reason why the treated composites had a higher flexural modulus is that the ZnONPs were able to penetrate the kenaf natural fiber and kenaf polymer interface region. This intrusion strengthened the interface between the natural fibers and the polymer matrix, as a direct consequence of which, the flexural properties of the composite substance are improved [86]. The enhanced strength and flexural modulus could be a result of several factors.

-

•

Improved Adhesion: ZnONPs may improve the bonding between the natural fibers and the polymer matrix. This could be due to the high surface area to volume ratio of nanoparticles, leading to an enhanced interaction with both components, thereby providing better adhesion and load transfer between them [87]. A significant adherence was created between KF and PM. This was most likely made possible by the presence of ZnO nanoparticles, which improve the molecular association that exists between KF and PM [88,89]. The molecular association between KF and PM could mean physical entanglement, chemical bonding, or other forms of interaction between the molecules of KF and PM. The addition of ZnONPs seems to enhance this interaction, leading to improved adhesion and thus a stronger, more durable composite. This could be a result of several factors. The ZnONPs may be physically linking the KF and PM, providing additional points of contact. Alternatively, the ZnONPs could be chemically bonding with both the KF and PM, effectively gluing them together [90]. Additionally, the ZnONPs could be altering the surface properties of the KF, increasing its compatibility with the PM and improving adhesion.

-

•

Stiffness of ZnONPs: ZnONPs themselves are quite rigid, so when they penetrate and embed into the kenaf fiber and polymer matrix, they can potentially increase the overall stiffness of the composite [91,92]. The nanoparticle inclusion likely acts as a filler, which can restrict the movement of the polymer chains and increase rigidity, leading to higher flexural modulus.

-

•

Barrier Effect: ZnONPs could also provide a 'barrier effect'. By interpenetrating the fiber-polymer interface, they could restrict the movement or slippage of natural fibers within the polymer matrix under stress, leading to better load distribution and increased flexural strength [93].

-

•

Stress Transfer: The effective stress transfer from the matrix to the fibers is critical for composite materials. The incorporation of ZnONPs could enhance this stress transfer efficiency, leading to an overall increase in the composite's flexural modulus [94].

-

•

Modification of Fiber Properties: ZnONPs could chemically or physically alter the properties of the natural fibers, possibly by inducing changes in the fiber surface or the fiber itself. These modifications could also lead to improved interface adhesion and increased flexural modulus [94].

Fig. 5.

The Flexural modules of the untreated UPE/KF composites and treated UPE/KF-ZnONPS composites.

According to the findings of the flexural modulus test, the flexural modulus began to decrease as soon as the percentage of ZnONPs reached a level greater than 2%. The reason for this is due to the fact that a larger percentage of nanoparticles have a propensity to clump together. As can be seen in Fig. 6, The accumulation of ZnONPs will lead to an augment in the number of interactions that occur between the nanoparticles on their own. as opposed to interactions between the nanoparticles and KF. Therefore, as can be seen, clusters of ZnONPs have been loaded onto the surface of the UPE/KF-ZnONPs combination, which has resulted in the formation of a more pronounced micro nanostructure. As a direct consequence of this, there is an accompanying decrease in modulus [95]. Researchers led by Sanya et al. [96] looked into how the stiffness, hardness, and strength of nanocomposites were affected by factors such as particle size, particle/matrix adherence, and particle loading of nanoparticles. According to the findings of the study, the composite's strength and durability are significantly influenced by all three variables, with particular emphasis on the particle-to-matrix adhesion. Table 4 presents, for the purpose of comparison, a percentage difference in the UPE/KF composite flexural modulus before and after KF treatment with various percentages of ZnONPs. With 1% and 2% ZnONP concentrations, all samples, regardless of the layer count, show an increase in the flexural modulus. This suggests an improvement in stiffness upon treatment with these lower ZnONP concentrations. For one-layer samples, an increase of 5.5% and 8.8% was observed with 1% and 2% ZnONPs, respectively. Similarly, for two-layer samples, the increments are 6.1% and 9.1%; for three-layer samples, these are 4.2% and 7.3%; and for four-layer samples, the increments are 3.5% and 5.9% [97,98].

Fig. 6.

SEM micrographs of UPE/KF-ZnONPs composite treated with 5% ZnONPs at 5000 × magnification.

Table 4.

Percentage difference in flexural modulus before and after treatment with ZnONPs.

| Sample | Flexural modulus (MPa) | Increment (%) | Decrement (%) |

|---|---|---|---|

| 1 layer prior and upon treating with 1% ZnONPs | 3000/3174 | 5.5% | – |

| 1 layer prior and upon treating with 2% ZnONPs | 3000/3288 | 8.8% | – |

| 1 layer prior and upon treating with 3% ZnONPs | 3000/2904 | – | 3.3% |

| 1 layer prior and upon treating with 4% ZnONPs | 3000/2819 | – | 6.4% |

| 1 layer prior and upon treating with 5% ZnONPs | 3000/2701 | – | 11.1% |

| 2 layer prior and upon treating with 1% ZnONPs | 3562/3794 | 6.1% | – |

| 2 layer prior and upon treating with 2% ZnONPs | 2562/3919 | 9.1% | – |

| 2 layer prior and upon treating with 3% ZnONPs | 3562/3401 | – | 4.7% |

| 2 layer prior and upon treating with 4% ZnONPs | 3562/3318 | – | 7.4% |

| 2 layer prior and upon treating with 5% ZnONPs | 3562/3157 | – | 12.8% |

| 3 layer prior and upon treating with 1% ZnONPs | 4003/4181 | 4.2% | – |

| 3 layer prior and upon treating with 2% ZnONPs | 4003/4316 | 7.3% | – |

| 3 layer prior and upon treating with 3% ZnONPs | 4003/3892 | – | 2.9% |

| 3 layer prior and upon treating with 4% ZnONPs | 4003/3704 | – | 8.1% |

| 3 layer prior and upon treating with 5% ZnONPs | 4003/3685 | – | 8.6% |

| 4 layer prior and upon treating with 1% ZnONPs | 4993/5171 | 3.5% | – |

| 4 layer prior and upon treating with 2% ZnONPs | 4993/5310 | 5.9% | – |

| 4 layer prior and upon treating with 3% ZnONPs | 4993/4818 | – | 3.6% |

| 4 layer prior and upon treating with 4% ZnONPs | 4993/4619 | – | 6.4% |

| 4 layer prior and upon treating with 5% ZnONPs | 4993/4592 | – | 8.7% |

When the ZnONP concentration rises to 3%, 4%, or 5%, however, a decrease in the flexural modulus is noted across all sample categories. For the one-layer samples, there are decrements of 3.3%, 6.4%, and 11.1% for 3%, 4%, and 5% ZnONPs respectively. The respective decrements for the two-layer samples are 4.7%, 7.4%, and 12.8%; for the three-layer samples, these values are 2.9%, 8.1%, and 8.6%; and for the four-layer samples, the decreases are 3.6%, 6.4%, and 8.7% at the 3%, 4%, and 5% ZnONPs concentrations respectively. Just as with the flexural strength, this data portrays a pattern where low ZnONP concentrations (1–2%) enhance the stiffness of the material, while higher concentrations (3–5%) lead to a decrease. This reduction in flexural modulus with increased nanoparticle concentration could potentially be attributed to defects or agglomerations induced within the composite, compromising its structural integrity and leading to less resistance to bending forces [99,100]. Again, the degree of decrement appears to be more prominent as the number of layers increases, hinting at potential increased complexity and internal stresses with more layers, which are further magnified by the high ZnONP concentrations. Therefore, this underscores the criticality of striking an optimal balance in nanoparticle use, keeping both layer count and nanoparticle concentration in consideration.

The increment of flexural modulus with 1% and 2% ZnONP concentrations indicates that these nanoparticles contribute to the stiffening of the composite materials. This enhancement can prove useful in applications where increased rigidity and resistance to deformation under stress are essential, such as in structural components for construction or in the manufacturing of automotive parts. However, the trend of decreasing flexural modulus with ZnONP concentrations above 2% suggests that a threshold of nanoparticle integration might exist, beyond which the flexural properties of the composite start to degrade. This decrement is a vital observation because it signifies a possible adverse effect of excessive nanoparticle usage, which could lead to a compromise in the performance of the composite material [101,102].

Furthermore, the higher decrement in flexural modulus with increased layers at higher ZnONP concentrations might indicate the presence of layer-layer interactions or interference that further complicates the composite structure. This phenomenon might be relevant in layered composite design and could influence how these composites are fabricated, particularly when it comes to deciding on the optimal number of layers and nanoparticle concentration [103,104]. In sum, these findings highlight the importance of careful nanoparticle integration in composite design, not just in terms of the amount of nanoparticles used but also considering the layer count in the composite. This kind of knowledge is essential in creating high-performance composite materials that maximize the benefits of nanotechnology while maintaining the integrity and functionality of the materials.

4.4. Impact kenaf fiber loadings on the flexural modulus

As demonstrated in Fig. 5, the flexural modulus of both untreated and treated KF composites increased as KF loading increased. The reason for this is that as the KF layers increase, a greater proportion of cellulosic material is incorporated into the composites, which results in an increase in the stiffness of the UPE composites [88,89]. This means that more and more of the UPE material is replaced by the KF material. As a result of this change in composition, the stiffness of the UPE composites increases. In this case, the increased stiffness means that the UPE composites will be less likely to bend or flex when a force is applied.

In light of these observations, one can draw the conclusion that the mechanical characteristics were enhanced at 40% loadings of KF. To achieve the necessary level of strength when an outdoor application of a natural fibre composite is being utilized, it is important to maintain strict control over the amount of fibre present [105]. This is done to minimize composites' moisture absorption and increase their durability [106]. The findings that have been obtained up to this point make it possible to draw the following conclusions: (a) The flexural properties of these composites are impacted in a complementary manner by the inorganic nanoparticles ZnONPs and the NFr loadings. (b) The most desirable combination of flexural properties was obtained with 1, and 2 (wt%) ZnONPs addition and 40 (wt%) fibre loadings. An ideal fibre loading and a proper ZnONPs amount inserted in UPE/KF-ZnONPs composites symbolize crucial variables in obtaining composites with solid mechanical characteristics even in moist conditions. Overall, the treatment of kenaf natural fiber composites with ZnONPs is a promising approach for improving the flexural properties of these materials. Further research is needed to optimize the treatment process and understand the long-term effects of this treatment on the performance of these composites.

5. Surface morphology

At a magnification of 5000 times, the pictures shown in Fig. 7 (a), (e), (h), (i), and (b) illustrate microscopic images of treated UPE/KF- ZnONPs with 1–5% of ZnONPs, respectively. At a concentration of 1% and 2% ZnONPs, the nanoparticles were shown to be uniform and equally dispersed throughout the sample. On the contrary, when considerably bigger proportions were employed, such as for 5% ZnONPs, the pattern of dispersion was quite distinct, and it was more inconsistent than when using smaller quantities, such as for 1% ZnONPs. Agglomeration was shown to occur as the number of ZnONPs increased, as seen in Fig. 7 (h), (i), and (b); this was possible due to the huge surface area and high surface energy of nanoparticles. Agglomeration refers to the process in which small particles or clusters of particles come together and form larger aggregates or clusters [107,108]. When the number of ZnONPs (i.e., the amount of nanoparticles) increases, the likelihood of agglomeration also increases. Due to their small size, nanoparticles have a higher ratio of surface area to volume, which leads to a greater exposure of their surface atoms to the surrounding environment. This surface energy tends to promote the aggregation of nanoparticles as they attempt to minimize their surface energy by coming together and forming larger clusters. The surface energy of the nanoparticles also contributes to their tendency to agglomerate [109,110]. Surface energy is the energy required to create a new surface, and it tends to be higher for smaller particles. This means that nanoparticles have a higher surface energy than larger particles, which leads to a greater driving force for them to come together and form larger aggregates. As a direct consequence of this, it is challenging to distribute them uniformly throughout the surface of the KF [111]. Fig. 7(a), demonstrates that the surface of treated KF fibres is rough and free of defects. As a result, it will make a contribution to the enhancement in the flexural attributes of the treated UPE/KF- ZnONPs, as shown in Fig. 3.

Fig. 7.

SEM micrographs of (a) UPE/KF-1% ZnONPs, (b) UPE/KF-5% ZnONPs, (c) UPE/10 wt% KF, (d) UPE/30 wt% KF, (e) UPE/KF- 2% ZnONPs composite (f) Untreated UPE/KF,(g) UPE/KF-1% ZnONPs, (h) UPE/KF-3% ZnONPs, (i) UPE/KF- 4% ZnONPs at 5000 × magnification.

In contrast to the KF that has been treated, the surface of the KF that has not been treated retains impurities of the nonfibrous materials. For instance, Fig. 7 (c) and (d), of UPE/10 wt% KF and UPE/30 wt% KF composites indicate that untreated KF composites have a significant gap between the NFr and the PM. This suggests that the IB between the untreated KF and the UPE-matrix resin was compromised, which led to worse flexural properties. The quality of the bond between the fibers and the resin is critical to the flexural properties of the composite material. If the IB is strong, it means that the fibers and the resin are tightly bound together, and the resulting composite material will have good flexural properties [112,113]. However, if the IB is weak, it means that the fibers and the resin are not tightly bound together, and the resulting composite material will have inferior flexural properties. In this case, the IB between the untreated natural fiber kenaf and the polymer matrix resin was compromised. This means that the bond between the two materials was weak, and as a result, the composite material had worse flexural properties. Flexural properties refer to the material's ability to bend or deform under stress without breaking [114]. If the interfacial bonding is weak, it can cause the composite material to be more susceptible to deformation and breakage under stress. Lai et al. [115] published an observation with a comparable morphological appearance that was quite close to this one.

[116] Research has shown that the type and structure of the IB between NFr and PM has an effect on the flexural properties of polymer matrix composites. Microscopic photos taken of fractured surfaces of treated and untreated KF composites are used to illustrate the IB between KF and the PM in Fig. 7 (e) and (d), respectively. Between the treated KF and the UPE, there were many instances of fibres breaking, there were no instances of fibres pulling out, and there were less holes noticed. This data provides support for the hypothesis that UPE adheres to the KF, hence boosting the capacity of composites to bear the load when the force was applied [117]. Nevertheless, gaps between the NFr and PM were visible in the untreated KF composites in Fig. 7(d). This indicates an insufficient IB between the NFr and PM, which further exacerbates the diminished capacity of composites to withstand the smashing after the force has been exerted [118]. In particular, the diminished capacity of the composites to withstand the smashing after the force has been exerted refers to the material's ability to resist impact or shock. When a force is applied to a composite material, such as by smashing it, the gaps between the fibers and the matrix can cause the material to fail more easily, leading to cracking, breaking, or other forms of damage. This can be exacerbated by insufficient interfacial bonding, which further weakens the material's ability to withstand the force [[119], [120], [121]].

In a comparative analysis of two SEM images taken at a magnification of 5000 times, we observe distinct differences in the microstructural characteristics of untreated UPE/KF composites in Fig. 7(f) and treated UPE/KF-ZnONPs composites in Fig. 7(g). Fig. 7(f) depicts untreated UPE/KF composites. In this image, we can observe noticeable voids within the composite structure. These voids indicate insufficient matrix to wet the KF, leading to a lack of proper encapsulation of the fibers by the matrix. Furthermore, the presence of these voids suggests weak interfacial bonding between the fiber and the matrix [7,8,115]. Weak interfacial bonding is a common issue in untreated natural fiber composites, often attributed to the inherent hydrophilic nature of natural fibers and their poor compatibility with hydrophobic polymer matrices [30,32]. In this case, the untreated kenaf fibers' surface characteristics and the unsaturated polyester matrix's chemistry result in a suboptimal wetting behavior, leading to inadequate fiber-matrix adhesion and the formation of voids.

On the other hand, the second SEM image, Fig. 7(g), showcases UPE/KF-ZnONPs composites. This image shows an apparent improvement in the interfacial bonding between the kenaf fibers and the polymer matrix. The micrograph reveals a continuous and well-distributed matrix phase with no visible voids. This enhanced interfacial bonding is attributed to the presence of ZnONPs in the composite. ZnONPs are known to promote better interfacial adhesion by modifying the surface characteristics of the fibers and improving their compatibility with the polymer matrix. The nanoparticles create a bridge between the fiber and the matrix, enhancing the wetting behavior and resulting in superior interfacial adhesion.

When ZnONPs are added to treated UPE/KF composites, the bond between the fiber and the matrix is greatly improved. The second SEM image shows that this has occurred due to the elimination of voids and the homogeneous distribution of the matrix phase. On the other hand, Fig. 7(f) shows that the untreated UPE/KF composites have suboptimal wetting behavior and weak interfacial bonding, which leads to void formation.

To improve the interfacial bonding and the flexural properties of untreated natural fiber kenaf composites, various techniques can be used, such as surface treatment of the fibers to enhance their adhesion to the resin, or modification of the resin to improve its compatibility with the fibers. By reducing the gaps between the fibers and the matrix, the composite material can become more resistant to impact and other forms of damage.

6. Conclusion

In this investigation, we assessed the impacts of ST using ZnONPs on the flexural properties of KF-reinforced UPE composites. Our findings indicate that the flexural strength and modulus of treated KF-reinforced UPE composites surpasses that of untreated KF-reinforced UPE composites. This enhanced strength and modulus results from improved adhesion between the treated KF and the UPE matrix. Furthermore, we observed a significant enhancement in the flexural properties of the UPE/KF nanocomposites when the nanofiller loading was increased from 1 to 2% wt. This was because of the hydrophobic surface modification that was applied, which allowed for an effective interaction between the ZnONPs filler and the PM. Treated KF exhibited a rougher surface, no fibre pull out, and smaller gaps between the fibres and matrix than untreated KF. These observations support the notion that the surface treatment enhances the interfacial bonding within the composite. However, we noted that ZnONPs exhibited agglomeration at higher concentrations of 3%, 4%, and 5%, likely attributed to the larger surface area to volume ratio and high surface energy of nanoparticles. In conclusion, the UPE/KF-ZnONPs composite shows promising potential for application in exterior building coverings including windows, door decks, covers, and breathable doors. The high flexural strength property of this composite material makes it an attractive candidate for such applications.

Consent for publication

All authors agreed to publish.

Availability of data and materials

Available upon request.

“Funding”: No funds, grants, or other support was received.

Author contribution statement

Mohammed muhanna mohammed: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Aeshah M. Mohammed: Anwar Jawad: Jawad Oleiwi: Azlin F. Osman: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Omar S. Dahham: Subash C. B. Gopinath: Analyzed and interpreted the data.

Bashir O. Betar: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data.

Rozyanty Rahman: Tijjani Adam: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Data availability statement

Data will be made available on request.

Additional information

No additional information is available for this paper.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The writers would like to thank the School of Materials Engineering at Universiti Malaysia Perlis for providing access to the laboratory. Many thanks go out to everyone who helped with this project in any way, whether explicitly or indirectly.

Contributor Information

Mohammed Mohammed, Email: hmn7575@yahoo.com.

Azlin F. Osman, Email: azlin@unimap.edu.my.

References

- 1.Sanjay M.R., Madhu P., Jawaid M., Senthamaraikannan P., Senthil S., Pradeep S. Characterization and properties of natural fiber polymer composites: a comprehensive review. J. Clean. Prod. 2018;172:566–581. [Google Scholar]

- 2.Islam M.H., Islam M.R., Dulal M., Afroj S., Karim N. The effect of surface treatments and graphene-based modifications on flexural properties of natural jute fiber composites: a review. iScience. 2022;25(1) doi: 10.1016/j.isci.2021.103597. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Achukwu E.O., Owen M.M., Shuib S.B., Umar A., Abdulmalik A.O., Danladi A.…Hazizan A.M. Effect of reprocessing on the service life properties of glass fiber-reinforced in-house polypropylene waste composites. Adv. Manuf. Polym. Compos. Sci. 2023;9(1) [Google Scholar]

- 4.Jumaidin R., Sapuan S.M., Jawaid M., Ishak M.R., Sahari J. Characteristics of thermoplastic sugar palm Starch/Agar blend: thermal, tensile, and physical properties. Int. J. Biol. Macromol. 2016;89:575–581. doi: 10.1016/j.ijbiomac.2016.05.028. [DOI] [PubMed] [Google Scholar]

- 5.Nazir M.H., Al-Marzouqi A.H., Ahmed W., Zaneldin E. Heliyon; 2023. The Potential of Adopting Natural Fibers Reinforcements for Fused Deposition Modeling: Characterization and Implications. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Karthikeyan S., Rajini N., Jawaid M., Winowlin Jappes J.T., Thariq M.T.H., Siengchin S., Sukumaran J. A review on tribological properties of natural fiber based sustainable hybrid composite. Proc. IME J. J. Eng. Tribol. 2017;231(12):1616–1634. [Google Scholar]

- 7.Amiandamhen S.O., Meincken M., Tyhoda L. Natural fibre modification and its influence on fibre-matrix interfacial properties in biocomposite materials. Fibers Polym. 2020;21:677–689. [Google Scholar]

- 8.Mohammed M., Rasidi M.S.M., Mohammed A.M., Rahman R., Osman A.F., Adam T.…Dahham O.S. Interfacial bonding mechanisms of natural fibre-matrix composites: an overview. Bioresources. 2022;17(4) [Google Scholar]

- 9.Mohammed M., Rahman R., Mohammed A.M., Adam T., Betar B.O., Osman A.F., Dahham O.S. Polymer Testing; 2022. Surface Treatment to Improve Water Repellence and Compatibility of Natural Fiber with Polymer Matrix: Recent Advancement. [Google Scholar]

- 10.Mohammed Mohammed, Jawad A.J.A.M., Mohammed A.M., Oleiwi J.K., Adam T., Osman A.F.…Jaafar M. Polymer Testing; 2023. Challenges and Advancement in Water Absorption of Natural Fiber-Reinforced Polymer Composites. [Google Scholar]

- 11.Bachtiar D., Sapuan S.M., Hamdan M.M. The effect of alkaline treatment on tensile properties of sugar palm fibre reinforced epoxy composites. Mater. Des. 2008;29(7):1285–1290. [Google Scholar]

- 12.Dittenber D.B., GangaRao H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Appl. Sci. Manuf. 2012;43(8):1419–1429. [Google Scholar]

- 13.Hafidz N.B.M., Rehan M.B.M., Mokhtar H.B. Effect of alkaline treatment on water absorption and thickness swelling of natural fibre reinforced unsaturated polyester composites. Mater. Today: Proc. 2022;48:720–727. [Google Scholar]

- 14.Cheng X., Liu J., Han C., Zhang X., Wu Z. Silane coupling agent impact on surface features of modification of basalt fibers and the rheological properties of basalt fiber reinforced asphalt. Construct. Build. Mater. 2023;366 [Google Scholar]

- 15.Babji R., Reddy U., Shakthivel S. Characteristic Investigation and Comparison between Vetiver fiber-reinforced polypropylene and polyethylene with Coconut shell powder and Maleic anhydride as filler and coupling agents. Mater. Today: Proc. 2020;24:2339–2351. [Google Scholar]

- 16.Lobregas M.O.S., Buniao E.V.D., Leaño J.L. Alkali-enzymatic treatment of Bambusa blumeana textile fibers for natural fiber-based textile material production. Ind. Crop. Prod. 2023;194 [Google Scholar]

- 17.Mishra T., Mandal P., Rout A.K., Sahoo D. Open Access; 2022. A State-Of-The-Art Review on Potential Applications of Natural Fiber-Reinforced Polymer Composite Filled with Inorganic Nanoparticle. Composites Part C. [Google Scholar]

- 18.Sebastian J., Thachil E.T., Mathen J.J., Madhavan J., Thomas P., Philip J.…Joseph G.P. Enhancement in the electrical and thermal properties of ethylene vinyl acetate (EVA) co-polymer by zinc oxide nanoparticles. Open J. Compos. Mater. 2015;5(3):79. [Google Scholar]

- 19.Li D., Dai D., Xiong G., Lan S., Zhang C. Composite nanocoatings of biomedical magnesium alloy implants: advantages, mechanisms, and design strategies. Adv. Sci. 2023 doi: 10.1002/advs.202300658. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Gomaa E.Z. Microbial mediated synthesis of zinc oxide nanoparticles, characterization and multifaceted applications. J. Inorg. Organomet. Polym. Mater. 2022;32(11):4114–4132. [Google Scholar]

- 21.Suwan T., Maichin P., Fan M., Jitsangiam P., Tangchirapat W., Chindaprasirt P. Influence of alkalinity on self-treatment process of natural fiber and properties of its geopolymeric composites. Construct. Build. Mater. 2022;316 [Google Scholar]

- 22.Owen M.M., Ishiaku U.S., Danladi A., Dauda B.M., Romli A.Z. vol. 1985. AIP Publishing LLC; 2018, July. Flexural properties of epoxy-coated sodium hydroxide and silane treated kenaf/recycled polyethylene tereph-thalate (RPET) composites: effect of chemical treatment. (AIP Conference Proceedings). 1. [Google Scholar]

- 23.Owen M.M., Achukwu E.O., Shuib S.B., Ahmad Z.R., Abdullah A.H., Ishiaku U.S. Effects of high‐temperature optimization and resin coating treatment on the mechanical, thermal, and morphological properties of natural kenaf fiber‐filled engineering plastic composites. Polym. Compos. 2023;44(4):2512–2529. [Google Scholar]

- 24.Owen M.M., Achukwu E.O., Romli A.Z., Md Akil H. Recent advances on improving the mechanical and thermal properties of kenaf fibers/engineering thermoplastic composites using novel coating techniques: a review. Compos. Interfac. 2023:1–27. [Google Scholar]

- 25.Armynah B., Anugrahwidya R., Tahir D. Composite cassava starch/chitosan/Pineapple Leaf Fiber (PALF)/Zinc Oxide (ZnO): bioplastics with high mechanical properties and faster degradation in soil and seawater. Int. J. Biol. Macromol. 2022;213:814–823. doi: 10.1016/j.ijbiomac.2022.06.038. [DOI] [PubMed] [Google Scholar]

- 26.Mohammed M., Betar B.O., Rahman R., Mohammed A.M., Osman A.F., Jaafar M.…Noriman N.Z. Zinc oxide nano particles integrated kenaf/unsaturated polyester biocomposites. J Renew Mat. 2019;7(10):967–982. [Google Scholar]

- 27.Mohammed M., Rahman R., Mohammed A.M., Osman A.F., Adam T., Dahham O.S.…Betar B.O. vol. 454. IOP Publishing; 2018, December. Effect of kenaf fibre mat layers and zinc oxide nanoparticle concentration on the mechanical and thermal properties of ZnONPs/kenaf/polyester composites. (IOP Conference Series: Materials Science and Engineering). 1. [Google Scholar]

- 28.Mohammed M., Rozyanty R., Mohammed A.M., Osman A.F., Adam T., Dahham O.S.…Betar B.O. Fabrication and characterization of zinc oxide nanoparticle-treated kenaf polymer composites for weather resistance based on a solar UV radiation. Bioresources. 2018;13(3):6480–6496. [Google Scholar]

- 29.Jagadeesh P., Puttegowda M., Boonyasopon P., Rangappa S.M., Khan A., Siengchin S. Recent developments and challenges in natural fiber composites: a review. Polym. Compos. 2022;43(5):2545–2561. [Google Scholar]

- 30.Mohammed M., Rahman R., Mohammed A.M., Betar B.O., Osman A.F., Adam T.…Gopinath S.C. Improving hydrophobicity and compatibility between kenaf fiber and polymer composite by surface treatment with inorganic nanoparticles. Arab. J. Chem. 2022;15(11) [Google Scholar]

- 31.Alhujaily M., Albukhaty S., Yusuf M., Mohammed M.K., Sulaiman G.M., Al-Karagoly H.…AlMalki F.A. Recent advances in plant-mediated zinc oxide nanoparticles with their significant biomedical properties. Bioengineering. 2022;9(10):541. doi: 10.3390/bioengineering9100541. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Dolez P.I., Arfaoui M.A., Dubé M., David É. Hydrophobic treatments for natural fibers based on metal oxide nanoparticles and fatty acids. Procedia Eng. 2017;200:81–88. [Google Scholar]

- 33.Wang X., Liu J., Chai Y. Thermal, mechanical, and moisture absorption properties of wood-TiO2 composites prepared by a sol-gel process. Bioresources. 2012;7(1):893–901. [Google Scholar]

- 34.Achukwu E.O., Odey J.O., Owen M.M., Lawal N., Oyilagu G.A., Adamu A.I. Physical and flexural properties of flamboyant (Delonix Regia) pod filled polyester composites. Heliyon. 2022;8(1) doi: 10.1016/j.heliyon.2022.e08724. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Noman M.T., Petru M., Louda P., Kejzlar P. Woven textiles coated with zinc oxide nanoparticles and their thermophysiological comfort properties. J. Nat. Fibers. 2022;19(12):4718–4730. [Google Scholar]

- 36.Bai T., Wang D., Yan J., Cheng W., Cheng H., Shi S.Q.…Han G. Wetting mechanism and interfacial bonding performance of bamboo fiber reinforced epoxy resin composites. Compos. Sci. Technol. 2021;213 [Google Scholar]

- 37.Hameed S.T., Qahtan T.F., Abdelghany A.M., Oraby A.H. Effect of zinc oxide nanoparticles on physical properties of carboxymethyl cellulose/poly (ethylene oxide) matrix. Phys. B Condens. Matter. 2022;633 [Google Scholar]

- 38.Ledford W.K., Kilbey S.M., II Impact of hydrogen bonding pendant groups in polymer grafted nanoparticles on interlayer adhesion and mechanical properties in material extrusion printing. Addit. Manuf. 2023;63 [Google Scholar]

- 39.Wang G., Wang R., Wang C., Tang C., Zhang F. Active responses of nanoparticle-polymer interface/interphase via the interfacial interaction redistribution. Int. J. Mech. Sci. 2023;243 [Google Scholar]

- 40.Mohammadipour-Nodoushan R., Shekarriz S., Shariatinia Z., Heydari A., Montazer M. Improved cotton fabrics properties using zinc oxide-based nanomaterials: a review. Int. J. Biol. Macromol. 2023 doi: 10.1016/j.ijbiomac.2023.124916. [DOI] [PubMed] [Google Scholar]

- 41.Xiao Z., Zhao Q., Niu Y., Zhao D. Adhesion advances: from nanomaterials to biomimetic adhesion and applications. Soft Matter. 2022;18(18):3447–3464. doi: 10.1039/d2sm00265e. [DOI] [PubMed] [Google Scholar]

- 42.Olonisakin K., Fan M., Xin-Xiang Z., Ran L., Lin W., Zhang W., Wenbin Y. Key improvements in interfacial adhesion and dispersion of fibers/fillers in polymer matrix composites; focus on pla matrix composites. Compos. Interfac. 2022;29(10):1071–1120. [Google Scholar]

- 43.Christy P.N., Basha S.K., Kumari V.S. Nano zinc oxide and nano bioactive glass reinforced chitosan/poly (vinyl alcohol) scaffolds for bone tissue engineering application. Mater. Today Commun. 2022;31 [Google Scholar]

- 44.Oun A., Manalo A., Alajarmeh O., Abousnina R., Gerdes A. Influence of elevated temperature on the mechanical properties of hybrid flax-fiber-epoxy composites incorporating graphene. Polymers. 2022;14(9):1841. doi: 10.3390/polym14091841. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Vinay S.S., Sanjay M.R., Siengchin S., Venkatesh C.V. Basalt fiber reinforced polymer composites filled with nano fillers: a short review. Mater. Today: Proc. 2022;52:2460–2466. [Google Scholar]

- 46.Shokrieh M.M., Kefayati A.R., Chitsazzadeh M. Fabrication and flexural properties of clay/epoxy nanocomposite and its polymer concrete. Mater. Des. 2012;40:443–452. [Google Scholar]

- 47.Wu C.L., Zhang M.Q., Rong M.Z., Friedrich K. Silica nanoparticles filled polypropylene: effects of particle surface treatment, matrix ductility and particle species on mechanical performance of the composites. Compos. Sci. Technol. 2005;65(3–4):635–645. [Google Scholar]

- 48.Joshi S., Hiremath A., Nayak S.Y., Jaideep J.P., Thipperudrappa S. Hybridization effect on the mechanical properties of basalt fiber reinforced ZnO modified epoxy composites. Polym. Compos. 2022;43(8):5704–5714. [Google Scholar]

- 49.Perumal K.S., Boopathi R., Saravanan P., Selvarajan L. Effect of zircon and anatase titanium dioxide nanoparticles on glass fibre reinforced epoxy with mechanical and morphological studies. Ceram. Int. 2023;49(13):21667–21677. [Google Scholar]

- 50.Owen M.M., Achukwu E.O., Romli A.Z., Abdullah A.H.B., Ramlee M.H., Shuib S.B. Thermal and mechanical characterization of composite materials from industrial plastic wastes and recycled nylon fibers for floor paving tiles application. Waste Manag. 2023;166:25–34. doi: 10.1016/j.wasman.2023.04.038. [DOI] [PubMed] [Google Scholar]

- 51.Ogbonna V.E., Popoola A.P.I., Popoola O.M., Adeosun S.O. A review on the recent advances on improving the properties of epoxy nanocomposites for thermal, mechanical, and tribological applications: challenges and recommendations. Polymer-Plastics Technology and Materials. 2022;61(2):176–195. [Google Scholar]

- 52.Assad H., Sharma S., Kaya S., Sharma P.K., Kumar A. Nanocomposites-Advanced Materials for Energy and Environmental Aspects. Woodhead Publishing; 2023. Overview and fundamentals of polymer nanocomposites; pp. 41–66. [Google Scholar]

- 53.Dias E., Chalse H., Mutha S., Mundhe Y., Ambhore N., Kulkarni A., Mache A. Review on synthetic/natural fibers polymer composite filled with nanoclay and their mechanical performance. Mater. Today: Proc. 2023;77:916–925. [Google Scholar]

- 54.Ejeta L.O. Nanoclay/organic filler-reinforced polymeric hybrid composites as promising materials for building, automotive, and construction applications-a state-of-the-art review. Compos. Interfac. 2023:1–24. [Google Scholar]

- 55.Vozniak A., Bartczak Z. Plastic deformation of high density polyethylene with extended-chain crystal morphology. Polymers. 2022;15(1):66. doi: 10.3390/polym15010066. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 56.Sui Y., Cui Y., Meng X., Zhou Q. Research progress on the correlation between properties of nanoparticles and their dispersion states in polymer matrix. J. Appl. Polym. Sci. 2022;139(19) [Google Scholar]

- 57.Zhang H., Ding Y., Li R., Shen Y., Lei J. Achieving exceptional improvement of yield strength in Mg–Zn–Ca alloy wire by nanoparticles induced by extreme plastic deformation. Mater. Sci. Eng. 2022;853 [Google Scholar]

- 58.Azmy E., Al-Kholy M.R.Z., Al-Thobity A.M., Gad M.M., Helal M.A. International Journal of Biomaterials; 2022. Comparative Effect of Incorporation of ZrO2, TiO2, and SiO2 Nanoparticles on the Strength and Surface Properties of PMMA Denture Base Material: an in Vitro Study. 2022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 59.Zare Y., Rhee K.Y. Simulation of tensile modulus of polymer carbon nanotubes nanocomposites in the case of incomplete interfacial bonding between polymer matrix and carbon nanotubes by critical interfacial parameters. Polymer. 2020;191 [Google Scholar]

- 60.Sharma R., Sharma D.K., Agarwal R., Rinawa M.L., Subbiah R., Kumar P.M. Investigating the effect of nanoclay content on the mechanical characteristics of natural fiber epoxy composite. Mater. Today: Proc. 2022;66:1319–1323. [Google Scholar]

- 61.Mirzamohammadi S., Eslami-Farsani R., Ebrahimnezhad-Khaljiri H. The effect of hybridizing natural fibers and adding montmorillonite nanoparticles on the impact and bending properties of eco‐friendly metal/composite laminates. Adv. Eng. Mater. 2023;25(12) [Google Scholar]

- 62.Çakır M.V. The synergistic effect of hybrid nano-silica and GNP additives on the flexural strength and toughening mechanisms of adhesively bonded joints. Int. J. Adhesion Adhes. 2023;122 [Google Scholar]

- 63.Azhagiri P., Senthilkumar N., Palanikumar K., Deepanraj B. Mechanical properties evaluation on hybrid AA6026 composites added with nanoclay and carbon fibers. Carbon Letters. 2023:1–14. [Google Scholar]

- 64.Huang X., Jiang P., Kim C., Ke Q., Wang G. Preparation, microstructure and properties of polyethylene aluminum nanocomposite dielectrics. Compos. Sci. Technol. 2008;68(9):2134–2140. [Google Scholar]

- 65.Chatterjee A., Islam M.S. Fabrication and characterization of TiO2–epoxy nanocomposite. Mater. Sci. Eng. 2008;487(1–2):574–585. [Google Scholar]

- 66.Arshad M.N., Mohit H., Sanjay M.R., Siengchin S., Khan A., Alotaibi M.M.…Rub M.A. Effect of coir fiber and TiC nanoparticles on basalt fiber reinforced epoxy hybrid composites: physico–mechanical characteristics. Cellulose. 2021;28:3451–3471. [Google Scholar]

- 67.Ja M.H., Majid M.A., Afendi M., Marzuki H.F.A., Fahmi I., Gibson A.G. Flexural properties of Napier grass fibre/polyester composites. Compos. Struct. 2016;136:1–10. [Google Scholar]

- 68.Mirzamohammadi S., Eslami-Farsani R., Ebrahimnezhad-Khaljiri H. The characterization of the flexural and shear performances of laminated aluminum/jute–basalt fibers epoxy composites containing carbon nanotubes: as multi-scale hybrid structures. Thin-Walled Struct. 2022;179 [Google Scholar]

- 69.Charoo N.A., Rahman Z., Khan M.A. Nanoarchitectonics in Biomedicine. William Andrew Publishing; 2019. Nanoparticles for improvement in oral bioavailability; pp. 371–410. [Google Scholar]

- 70.Masoudifar M., Nosrati B., Mohebbi Gargari R. Effect of surface treatment and titanium dioxide nanoparticles on the mechanical and morphological properties of wood flour/polypropylene nanocomposites. Int. Wood Prod. J. 2018;9(4):176–185. [Google Scholar]