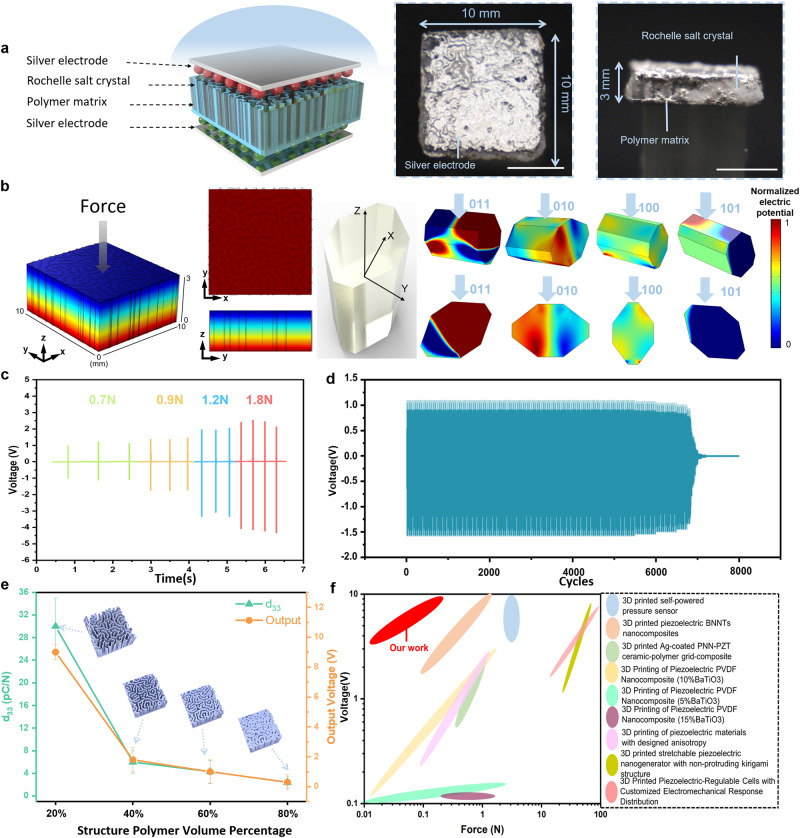

Fig. 2. Piezoelectric performance of 3D-printed-RSC.

a Illustration of the tested 3D-printed-RSC sample electrodes and photos of vertical free fall piezoelectric performance test process using weights (scale bar from left to right, 5 mm, 5 mm, 25 mm); b Piezoelectric FEM simulation of the 3D-printed-RSC sample, simulations were conducted in four different directions of piezoelectric individual RS crystals; c Piezoelectric output at different frequencies corresponding to different force magnitudes; d The output voltage over 8000 cycles cyclic impact test under 2 Hz frequency; e Voltage output and piezoelectric coefficient comparison line for the identical test conditions corresponding to the polymer ratio of different 3D-printed-RSC. Error bars represent standard deviation(n = 10); f Comparison of output voltage and force of 3D-printed-RSC with other structures47–53.