Abstract

Celiac disease ranks highest among immunological disorders attributed to gluten consumption thus, posing great demands on gluten-free products. Rice is a gluten-free cereal with promising dietary applications. Ofada rice, a native southwestern Nigerian variety, can be improved with sourdough technology to develop functional aglutenic bread. Ofada rice sourdough bread (ORSB) was made with Fructilactobacillus fructivorans RY1, Weissella viridescens RY9 and Lactobacillus acidophilus RY10 as individual and combined starter cultures. Physical qualities, proximate contents, sensorial attributes and shelf-life of the ORSBs were evaluated. Sourdough bread with the highest (3.10 cm3/g) and lowest specific volumes (2.02 cm3/g) were the sample made single culture of W. viridescens and F. fructivorans, respectively. The highest crude protein (8.48 %) was found in ORSB with only F. fructivorans and ORSB with L. acidophilus singly had the highest content (0.44 %) of crude fibre. Nevertheless, the least crude protein (5.25 %) and crude fibre (0.28 %) were observed in samples containing F. fructivorans, W. viridescens, and L. acidophilus as combined starters. The sourdough bread with F. fructivorans as a starter scored best for texture and overall acceptability. The ORSBs had shelf-life ranging from three to four days. It was revealed in the study that using the specific LAB starters could improve the physicochemical attributes and acceptability of bread from Ofada rice flour.

Keywords: Ofada rice, Sourdough technology, Starter cultures, Lactic acid bacteria, Fructilactobacillus fructivorans

1. Introduction

Cereals are important staple foods all over the world. They can be cooked into delicacies or processed into varieties of secondary food products such as flour, pasta and bread [1]. Wheat and similar cereals including kamut, barley and rye containing gluten [2]. Nevertheless, gluten is found to stimulate and immunological toxic reaction in celiac disease (CD) patients. Celiac disease damages the intestine of the susceptible individuals, resulting in vitamin deficiency, anaemia and emaciation of the patient. This autoimmune disease is increasing significantly and no other effective treatment has yet been than to be placed on a gluten-free diet [3].

Rice (Oryza sativa) is a gluten-free grain cultivated under various environmental conditions. In West Africa, there are several types of locally grown rice cultivars, with Ofada rice being one of them. Ofada rice is upland rice with unique short, strong grains with brown hoops that are cultivated without the use of chemicals [4]. A town in Ogun-State, South-Western Nigeria, named Ofada was the first historical place of its cultivation and has since been generally referred to as Ofada rice [5]. From its previously underutilized status, there has recently been an increase in demand for Ofada rice production; this could be attributed to the discovery of its good taste, flavour, and high nutritional content [6], which has also been popularized by its prevalent use as a delicacy in festivities.

Sourdough consists of flour and water mixture, with lactic acid bacteria (LAB) and yeasts as fermentation agents to cause acidity, leavening and the generation of aroma compounds. It is a metabolically active intermediate product with revitalization potential. Ability of sourdough to improve the texture and flavour of cereal food products has been well proven [7,8]. The singnificannce of sourdough fermentation is also found in its ability to improve non-microbiologically sterile flours and make them suitable for consumption, thereby enhancing safety. In traditional bread leavening, sourdough is a key ingredient; as its production improves the taste, physical attributes and storage of bread [[9], [10], [11]].

Lactic acid bacteria are beneficial in the production of fermented foods and as probiotics. Their major metabolic functions include lactic fermentation, proteolysis, and the production of volatile and antimicrobial substances [12]. The beneficial effects of LAB in sourdough bread fermentation include: lowering the pH, inhibiting mould growth, increasing bread shelf-life, reducing the use of chemical preservatives, hydrolyzing pro-rich gluten fragments, improving nutritional and sensory qualities, and enhancing stress resistance via the arginine-deiminase (ADI) pathway [13,14]. Experiments have revealed the significant impact of LAB on the physical, chemical, rheological and sensorial attributes of sourdough bread [10,15,16]. The LAB in sourdough could be from the flour material as well as introduced from the baking ingredients, or the environment. Thus, selecting suitable native microorganisms in spontaneously fermented sourdough is a promising technique for improving gluten-free bread quality [17]. Despite the increasing popularity of sourdough bread made with other rice varieties, there is limited information on the use of Nigeria's indigenous Ofada rice and its potential in sourdough production. An initial preliminary spontaneous fermentation test was conducted to understand the intrinsic fermentation characteristics of Ofada rice and assess its potential influence on potential starter cultures. Premise, this study aims to evaluate Ofada rice potential for sourdough bread using selected choices of starter cultures (Fructilactobacillus, Lactobacillus and Weissella species singly and in combination), based on previously screened functional properties such as proteolytic, acidification, pathogenicity activities among others.

2. Materials and methods

2.1. Collection and processing of sample

Ofada rice cultivar (FARO 58) grains were obtained from Landmark University's Teaching and Research Farm in Omu-Aran, Kwara State, Nigeria (8°07′30.9″N; 5°04′53.8″E). Corn starch was purchased from FINCAP, Lagos, Nigeria, salt and sugar were products of Dangote, Lagos, Nigeria, baking fat and yeast powder were from Simas, Jakarta, Indonesia and STK Royal, China, respectively. To process the rice, dirt was manually removed, and 5 kg of the cereal was ground using a hammer mill. The resulting flour was sieved into uniform particle sizes of 1 mm and was kept sterile in a clean sack before refrigeration at 4 °C until required [18].

2.2. Preparation and natural fermentation of Ofada rice sourdough

Rice flour and water were combined in a 1:1 ratio to make three batches of sourdough, which were then subjected to spontaneous fermentation at 27 ± 2 °C. The sourdough's temperature, pH, total titratable acidity, and leavening were measured at intervals of 0, 8, 24, and 48 h [19]. The temperature was measured by inserting a laboratory thermometer after homogenizing 1 g of the dough in 10 mL of distilled water. The pH was measured by dipping a pH probe into the homogenate.

One gram (1 g) of the dough was mixed with 9 mL of distilled water to determine the total titratable acidity (TTA) of the sourdough. It was titrated against 0.1 mol/L NaOH till the end point after adding two to three drops of phenolphthalein - 0.1 % (w/v). To measure the degree of leavening, the height of the sourdough in the beaker was measured using a meter rule, and the difference between the initial and final levels of the sponge was recorded.

2.3. Preparation of starter cultures

The starter cultures, Fructilactobacillus fructivorans RY1, Weissella viridescens RY9, and Lactobacillus acidophilus RY10, were acquired from the Department of Food Science and Microbiology, Landmark University, Kwara State, Nigeria. These LAB were previously isolated from rice and characterized for functional properties based on standard protocol (Table 1). The isolates were added to 10 mL of de Man-Rogosa-Sharpe (MRS) broth (TM Media, Delhi, India) to prepare the starters, which were then cultured at 37 °C overnight. A 100 mL of MRS broth were inoculated with 0.1 mL of the overnight-grown culture, and the mixture was then anaerobically incubated for 24 h at 37 °C. On MRS agar (TM Media, Delhi, India), the cell population was determined. Following preparation, the broth culture was centrifuged (Anke TDL-5000B, Shanghai, China) for 5 min at 5000 rpm, rinsed twice in saline water, and then centrifuged one more. In accordance with Olojede et al. (2022), the cell suspension was employed to make sourdough [8].

Table 1.

Functional properties of Selected Starter Culture.

| Test |

Lactobacillus fructivorans |

Weissella viridescens |

Lactobacillus acidophilus |

|

|---|---|---|---|---|

| Proteolytic (mm) | 40 | 37 | 43 | |

| Acidification (Lactic acid conc. mg/mL) | 24 | 0.50 | 0.37 | 0.57 |

| 48 | 0.87 | 0.63 | 1.37 | |

| 72 | 0.93 | 0.90 | 1.43 | |

| Pathogenicity activities | Gelatin | Negative | Negative | Negative |

| Haemolysis | Negative | Negative | Negative | |

2.4. Preparation of Ofada rice sourdough with starter cultures

To make sourdough, 100 g of rice flour was mixed with 90 mL of water and 10 mL of starter culture suspension. The starters have a cell density of roughly 109 CFU/mL. The batter fermented for 24 h at 27 ± 2 °C. The isolates were used both independently and as mixed starters [20].

2.5. Production of Ofada rice sourdough bread

The 24-h-old sourdough was one of the ingredients utilized to make ORSB. The way the ingredients were put together followed the modified Olojede et al. (2020) technique [16]. The proportions of the ingredients were as follows: 105 % tap water, 105 % Ofada rice flour, 30 % maize starch, 1 % baking oil, 4 % sugar, 2 % salt, and 2 % yeast. In the formula, the weight of the flour is equal to 100 %. The whole amount of Ofada rice flour and corn starch (100 %) was determined to be treated as flour weight basis. A similar amount of fermented flour as a sourdough was used to replace the 20 % flour and 20 % water found in traditional sourdough bread. According to the weight of the flour, the amounts of the other ingredients were calculated. For 5 min, the components were well blended at 1300 rpm with a hand food mixer (Kenwood KW 7710, Havant, UK). The batter was weighed into a prepared baking pan at a weight of 200 g (500 mL volume, 6 × 8 × 12 cm3). The batter was proofed for 35 min at 30 °C in a water bath (Grant SAP 34, Cambridgeshire, UK), and it was then baked for 45 min at 180 °C in an oven (Saisho Model S923, Tokyo, Japan). Before analysis, the bread loaves were de-panned and left for 1 h to cool completely on cooling racks at room temperature. Based on the sourdough starter added, the samples were coded thus: FfB (single culture of F. fructivorans RY1), WvB (single culture of W. viridescens RY9), LdB (single culture of L. acidophilus RY10), FWB (co-culture of F. fructivorans RY1 and W. viridescens RY9), FLB (co-culture of F. fructivorans RY1 and L. acidophilus RY10), WLB (co-culture of W. viridescens RY9 and L. acidophilus RY10), FWLB (co-culture of F. fructivorans RY1, W. viridescens RY9 and L. acidophilus RY10) and CoB (without sourdough addition).

2.6. Measurement of physical properties of sourdough bread

The height of the loaf was measured using a meter rule and recorded in centimeters, while the weight was measured using a laboratory weighing balance (Ohaus, PA512 Pine Brook, NJ UK). The specific volume of the bread was estimated by calculating the volume to mass ratio in cm3/g, and the bread volume was calculated using a modified Rapeseed displacement approach in which millet was used in place of rapeseed [16]. Bake loss was recorded as weight difference between of sample before and after baking into loaf.

2.7. Proximate and mineral composition analysis Ofada rice sourdough bread

The moisture, ash, crude protein, crude fat, crude fibre and carbohydrate compositions were determined on a dry matter basis using the procedure of AOAC International [21]. For determination of mineral contents of the samples, each collected ash was treated with 10 % HCl and analyzed for sodium, potassium, calcium, magnesium and phosphorus using atomic absorption spectrophotometer (AAS) (Buck Scientific Instrument Model-200A/2010, Norwalk, Connecticut, 06855).

2.8. Sensory evaluation of Ofada rice sourdough bread

This analysis used a modified version of the method of Ogunsakin et al. (2015) [19]. Between the ages of 20 and 50, 25 semi-trained assessors (15 - females, 10 - males) were given a sensory evaluation form. The samples were rated for the following characteristics: appearance, taste/flavor, texture, aroma/smell, softness, gumminess, and overall acceptability on a scale of 1–9, with 9 denoting extreme like and 1 severe dislike. Informed consent to be involved in the sensory assessment was obtained from all assessors and each of them was allowed to pull out from the panel, as they desired, with no consequence attached.

2.9. Shelf-life of Ofada rice sourdough bread

The ORSBs were kept in clean polythene bags and then placed on a shelf at room temperature between 27 ± 2 °C to ascertain how long it would take for obvious mould development to appear [8].

2.10. Statistical analysis

The statistical analysis made use of the one-way Analysis of Variance (ANOVA) method. Statistical variations between samples were examined at p < 0.05. Using SPSS version 15.0 software (SPSS Inc., Chicago, IL, USA), the Duncan's multiple range test (DMRT) was employed to differentiate between the mean values.

3. Results and discussion

3.1. Physico-chemical analysis during spontaneous fermentation

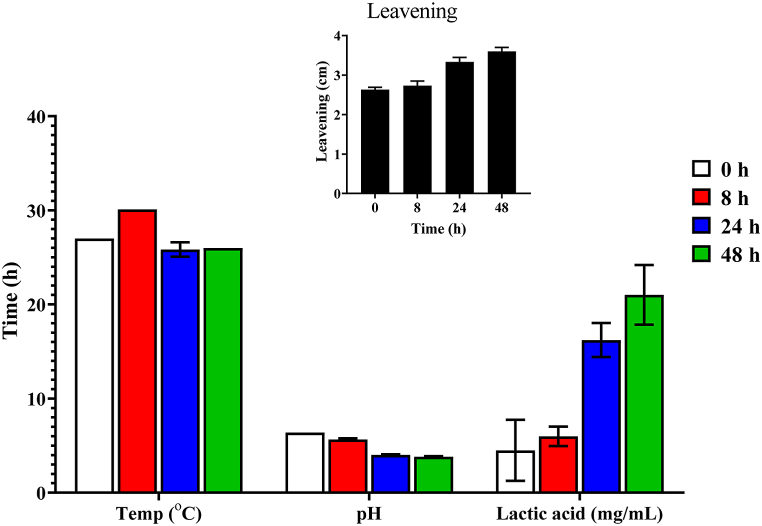

The purpose of the initial spontaneous fermentation was to evaluate the feasibility of producing sourdough bread from Ofada rice. The temperature of the spontaneous sourdough decreased with time from 27 °C at the start of the fermentation (0 h) to 26 °C at the completion of the fermentation (48 h) (Fig. 1). Additionally, there was a sharp drop in pH from 6.8 to 3.8 from the start of the fermentation until the finish. At 0 h and 48 h, respectively, the amount of lactic acid generated rose from 0.5 to 2.3. At 0 h, the sourdough leavening was 2.6 cm; at 48 h, it was 3.6 cm. Similar to earlier observations, the production of lactic acid and leavening increased significantly while pH fell (p < 0.05) [22,23]. Because it tends to extend the shelf-life of the bread, this increase in lactic acid production is beneficial for sourdough [17]. This experiment revealed that the temperature of the fermenting meal varied even as fermentation time increased. The results of this experiment confirmed the findings reported by Ogunsakin et al. (2017) on variability of temperature with increase in fermentation period in sorghum-based sourdough produced with starter cultures [22].

Fig. 1.

Changes in Temperature, pH, Total Titratable Acidity, and Leavening of Ofada Rice during Spontaneous Fermentation.

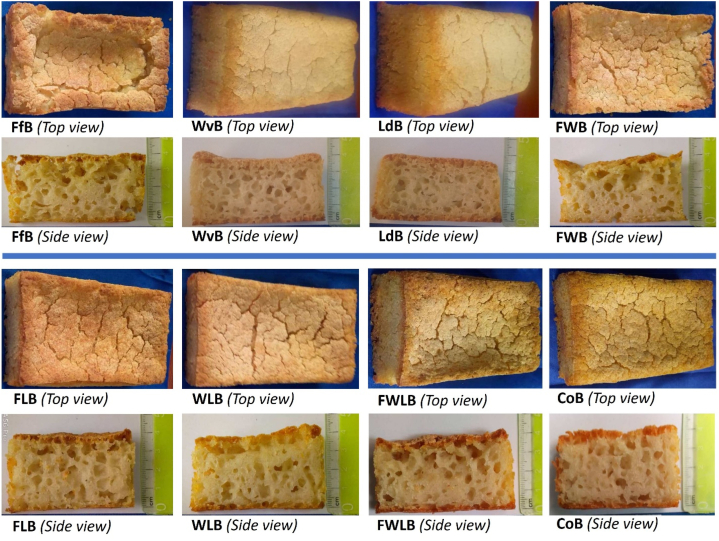

3.2. Appearance and shelf-life of Ofada rice sourdough bread

The ORSB's external appearance and internal structures are visually distinct, as shown in Fig. 2. The color of the sourdough bread's crumb is greatly influenced by the ingredients employed. It was found that the ORSB crust ranged in color from creamy to slightly dark cream. WvB and LdB showed characteristic fluffy and smooth texture, while other bread samples had crumbed structures with cracks observed in the crust. The ORSBs that were individually inoculated with LAB starter culture displayed more rounded corners and a top that resembled the shape of regular bread. The enhanced external form and internal structure of the Ofada rice sourdough bread from the individual LAB starters is a significant improvement (p < 0.05) because the vast majority of gluten-free loaves are infamous for having technical flaws such as a hard and pitted crumb, deficiency of cellular structure and cracked crust [24].

Fig. 2.

Comparison of external appearance and internal structures of Ofada rice sourdough breads made with different starter culture FfB: sourdough with Fructilactobacillus fructivorans RY1; WvB: with Weissella viridescens RY9; LdB: with L. acidophilus RY10; FWB: with F. fructivorans RY1 and W. viridescens RY9; FLB: with F. fructivorans RY1 and L. acidophilus RY10; WLB: with W. viridescens RY9 and L. acidophilus RY10; FWLB with F. fructivorans RY1, W. viridescens RY9 and L. acidophilus RY10; CoB: without sourdough.

Table 2 displays the ORSB's weight, height, specific volume, and shelf life. While the bread samples' heights varied from 3.76 cm for FWLB to 3.30 cm for WvB and LdB, their weights ranged from 159.50 g for WvB to 144.97 g for FfB. The volume of the WvB sample was 495.00 cm3, while the volume of the CoB control bread sample was 196.66 cm3. For the bread samples WvB and FfB, the percentage bake loss varied from 20.25 to 27.52 %. In terms of bread weight, height, and bake loss, the difference between the breads with starters and the uninoculated bread (CoB) was not significant (p < 0.05). The specific volume for the bread sample, however, revealed that WvB had the highest value and was statistically different from the other bread samples with a value of 3.10 ± 0.07 mL/g. The most essential metric in bread manufacture, according to Ni et al. (2020), is the specific volume since it indicates how much gas will ultimately remain in the loaf and influences consumer preference [25]. This is explained by the heterofermentative LAB used for sourdough, which may produce lactic acid, CO2, and ethanol [26]. In this process, the metabolic activity of LAB could also work synergistically with yeast in CO2 production [27]. The specific volume enhance bread production because the high bread weight and height are caused by leavening, which is caused by CO2. As a result, baked loss is reduced. A similar finding on specific volume results in this study was reported by Olojede et al. (2022) in sorghum-based sourdough bread, as Weissella confusa strain resulted in higher specific volume compared to Pediococcus pentosaceus [8]. Therefore, using Weissella species would be a preferred choice for the leavening of ORSB. We also observed that using starter cultures in combination reduced the resulting specific volume of the sourdough bread.

Table 2.

Physical properties and shelf-life evaluation of Ofada rice sourdough breads.

| Sample | Weight (g) | Height (cm) | Volume (cm3) | Specific Volume (cm3/g) | Bake loss (%) | Shelf-life (days) |

|---|---|---|---|---|---|---|

| FfB | 144.97 ± 15.08a | 3.70 ± 0.20a | 291.67 ± 7.64d | 2.02 ± 0.18d | 27.52 ± 7.54a | 3 |

| WvB | 159.50 ± 2.00a | 3.33 ± 0.35a | 495.00 ± 5.00f | 3.10 ± 0.07f | 20.25 ± 1.00a | 4 |

| LdB | 156.43 ± 1.69a | 3.33 ± 0.15a | 376.67 ± 15.28e | 2.41 ± 0.10e | 21.78 ± 0.85a | 4 |

| FWB | 152.87 ± 2.16a | 3.50 ± 0.00a | 210.00 ± 0.00abc | 1.37 ± 0.02abcd | 23.57 ± 1.08a | 3 |

| FLB | 145.27 ± 7.17a | 3.67 ± 0.21a | 233.33 ± 2.89c | 1.61 ± 0.10c | 27.37 ± 3.58a | 4 |

| WLB | 151.97 ± 2.58a | 3.63 ± 0.12a | 180.00 ± 26.46a | 1.18 ± 0.16a | 24.02 ± 1.29a | 4 |

| FWLB | 151.37 ± 4.2a | 3.77 ± 0.06a | 223.33 ± 15.28bc | 1.48 ± 0.08bc | 24.32 ± 2.10a | 4 |

| CoB | 149.53 ± 3.14a | 3.70 ± 0.00a | 196.67 ± 15.28ab | 1.31 ± 0.08ab | 25.23 ± 1.57a | 3 |

FfB: sourdough with Fructilactobacillus fructivorans RY1; WvB: with Weissella viridescens RY9; LdB: with L. acidophilus RY10; FWB: with F. fructivorans RY1 and W. viridescens RY9; FLB: with F. fructivorans RY1 and L. acidophilus RY10; WLB: with W. viridescens RY9 and L. acidophilus RY10; FWLB with F. fructivorans RY1, W. viridescens RY9 and L. acidophilus RY10; CoB: without sourdough. Values given as means of three independent assays ± standard deviations. Means with different letter superscripts in the same column indicate significant differences (p < 0.05).

With the exception of bread FfB and LWB, which had a shelf-life of 3 days and were identical to the control (CoB), all of the bread prepared with starter culture alone or in combination (WvB, LdB, FLB, WLB, FWLB) had a comparable shelf-life of 4 days (Table 2). This finding contrasts with that of a study by Latou et al. (2010) on wheat bread, which found that the bread had a shelf life of 4–9 days [28]. However, in that study, more baking fat (10 g) and sugar (30 g) were used compared to 2 g and 1 g, respectively used in the present study. It should be noted that the shelf-life discrepancies may be caused by the use of a higher sourdough percentage (100 %) than the 20 % utilized in this study. A closer shelf-life of 4–5 days was recorded for gluten-free sorghum sourdough bread in a prior study [8].

3.3. Proximate and mineral compositions

Table 3 shows the proximate contents of the ORSB. Their moisture content ranged from 45.44 % in FfB to 36.61 % in CoB (Control). FfB had a significantly (p < 0.05) high amount of crude protein (8.48 %) compared to other bread samples. The ash content was not significantly different across the bread samples, while LdB had the highest crude fat content of 3.41 %. The moisture level of the bread samples in this study is similar to those reported by Ogunsakin et al. (2015) [19]. Moisture content increases the bread loaf volume [29] Additionally, the amount of moisture in bread affects its sensory, physical, and microbiological properties. The significantly high crude protein reported in FfB could result from the symbiotic proteolytic activity of F. fructivorans and yeast that liberate the bound amino acids and small peptides from proteins in the bread samples for measurement in the Kjeldahl protein analysis [13,30]. Proteolysis is crucial in the bread industry because it enhances the nutritional and sensory qualities of baked goods [31].

Table 3.

Proximate and mineral compositions of the Ofada rice sourdough breads.

| Sample | FfB | WvB | LdB | FWB | FLB | WLB | FWLB | CoB |

|---|---|---|---|---|---|---|---|---|

| Moisture (%) | 45.44 ± 2.16a | 40.71 ± 2.46a | 39.25 ± 1.84a | 39.58 ± 1.49a | 37.59 ± 4.36a | 38.12 ± 3.58a | 36.84 ± 5.63a | 36.61 ± 2.21a |

| Ash (%) | 1.32 ± 0.53a | 1.80 ± 0.09a | 1.70 ± 0.18a | 1.60 ± 0.39a | 1.6500 ± 0.30a | 1.3167 ± 0.53a | 1.64 ± 0.24a | 1.58 ± 0.16a |

| Crude Fat (%) | 1.77 ± 0.30ab | 2.51 ± 0.46ab | 3.41 ± 0.38b | 1.78 ± 0.28ab | 1.24 ± 0.14ab | 2.60 ± 1.44ab | 1.49 ± 0.10ab | 1.01 ± 0.01ab |

| Crude Protein (%) | 8.48 ± 0.06e | 7.28 ± 0.03d | 7.46 ± 0.03d | 6.48 ± 0.06bc | 6.61 ± 0.06c | 6.36 ± 0.04b | 5.25 ± 0.06a | 7.31 ± 0.13d |

| Crude fibre (%) | 0.43 ± 0.00b | 0.41 ± 0.00b | 0.43 ± 0.00b | 0.43 ± 0.00b | 0.44 ± 0.00c | 0.29 ± 0.00a | 0.28 ± 0.00a | 0.40 ± 0.01d |

| Carbohydrate (%) | 45.45 ± 2.76a | 47.65 ± 0.8a | 49.89 ± 2.94a | 49.97 ± 1.18a | 52.14 ± 6.50a | 50.88 ± 3.71a | 55.39 ± 1.96a | 54.10 ± 2.67a |

| Sodium (mg/100 g) | 1.22 ± 0.03b | 1.50 ± 0.07c | 2.19 ± 0.00e | 0.20 ± 0.00a | 1.75 ± 0.00d | 1.70 ± 0.00d | 1.72 ± 0.00d | 2.58 ± 0.03f |

| Potassium (mg/100 g) | 0.40 ± 0.00a | 0.39 ± 0.00a | 0.50 ± 0.00c | 0.45 ± 0.00b | 0.45 ± 0.00b | 0.50 ± 0.00c | 0.45 ± 0.00b | 0.65 ± 0.00d |

| Calcium (mg/100 g) | 0.01 ± 0.01b | 0.01 ± 0.01a | 0.01 ± 0.01c | 0.00 ± 0.00e | 0.02 ± 0.02c | 0.03 ± 0.03a | 0.02 ± 0.02d | 0.02 ± 0.02a |

| Magnesium (mg/100 g) | 0.31 ± .00d | 0.28 ± 0.00c | 0.39 ± .012f | 0.33 ± 0.00e | 0.23 ± 0.00c | 0.22 ± .00c | 0.44 ± 0.01g | 0.21 ± 0.00a |

| Phosphorus (mg/100 g) | 0.19 ± 0.00b | 0.16 ± 0.00a | 0.19 ± 0.01b | 0.17 ± 0.00a | 0.17 ± 0.00a | 0.18 ± 0.00a | 0.20 ± 0.00c | 0.21 ± 0.01c |

The results are the averages of three separate assays, ± standard deviations. Significant differences (p < 0.05) are shown by means with distinct letter superscripts in the same row.

According to Table 3, the mineral content of the ORSBs shows that sodium was prevalent; with CoB (control sample) having the highest value of 2.58 mg/100 g in addition to the highest potassium 0.65 mg/100 g and phosphorus 0.21 mg/100 g. calcium was highest in WLB (0.03 mg/100 g), while FWLB had the highest magnesium (0.44 mg/100 g). The general reduction in the mineral composition of bread samples with starter culture could be due to the level of utilization of these elements at different degrees by the microorganism for their metabolic activities.

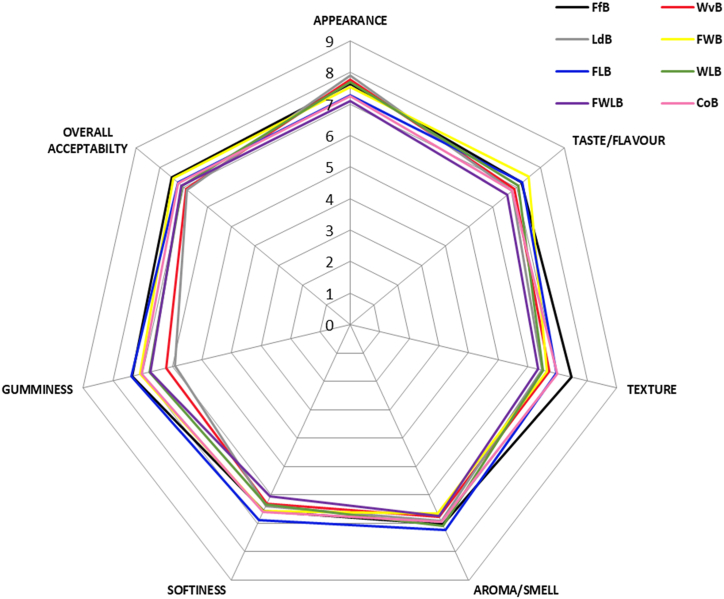

3.4. Sensorial attributes of sourdough bread

Fig. 3 shows the organoleptic properties of the Ofada sourdough bread from panel data represented with a 9-point hedonic scale. The sample FLB was preferred most for its softness, aroma/smell, and gumminess. Sample LdB received the best appearance, while FfB had the best texture and FWB had the finest flavor. ORSB FfB, however, scored the highest overall for acceptance. Sourdough fermentation with LAB can enhance not only the physical properties of food but also its sensory qualities [32]. The aroma is formed by the precursors the LAB produces. The presence of CO2 has a positive impact on the flavor and acceptability of the sourdough bread [11]. All of the LAB utilized in these sourdough studies are heterofermentative, which means they generate acetic acid, CO2, and ethanol, which results in additional flavour compounds [33].

Fig. 3.

Evaluation of organoleptic properties of starter-cultured Ofada rice sourdough bread.

4. Conclusion

In this present study, sourdough bread was produced from Ofada rice flour fermented with individual and combined strains of Fructilactobacillus, Lactobacillus and Weissella. The sourdough bread produced with F. fructivorans received the highest overall consumer rating. In terms of specific volume and sourdough bread texture, ORSB produced separately with W. viridescens and L. acidophilus could be considered the best. The particular starter cultures utilized to make the gluten-free Ofada rice sourdough bread helped the improved the nutritional, and sensory qualities. As a result, the identified starters demonstrated a promising application for Ofada rice product development, with improved safety and consumer acceptability. However, combining these starters may reduce the quality of the products' output. These findings point to further research into the improved quality and biopreservative potentials of starters in Ofada rice bread for gluten-intolerance patients.

Ethics statement

The sensory evaluation of the bread samples which was conducted during this experiment was in accordance with established ethical guidelines, and informed consent was obtained from the participants.

Funding statement

This research received no external funding.

Author contribution statement

Remilekun M. Thomas: Conceived and designed the experiments; Performed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Christopher R. Falegan: Conceived and designed the experiments; Wrote the paper.

Ayoyinka O. Olojede: Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Emmanuel O. Oludipe: Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Olorunfemi D. Awarun, Gladys O. Daodu: Performed the experiments; Wrote the paper.

Data availability statement

Data will be made available on request.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

Authors are grateful to the Faculty and Staff of the Department of Microbiology, Landmark University for their support during this research.

References

- 1.Khaneghah A.M., Farhadi A., Nematollahi A., Vasseghian Y., Fakhri Y. A systematic review and meta-analysis to investigate the concentration and prevalence of trichothecenes in the cereal-based food. Trends Food Sci. Technol. 2020;102:193–202. doi: 10.1016/j.tifs.2020.05.026. [DOI] [Google Scholar]

- 2.Arendt E.K., Moroni A., Zannini E. Medical nutrition therapy: use of sourdough lactic acid bacteria as a cell factory for delivering functional biomolecules and food ingredients in gluten free bread. Microb. Cell Factories. 2011;10(1):1–9. doi: 10.1186/1475-2859-10-S1-S15. http://www.microbialcellfactories.com/content/10/S1/S15 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Skjellerudsveen B.M., Omdal R., Hetta A.K., Kvaløy J.T., Aabakken L., Skoie I.M., Grimstad T. Fatigue: a frequent and biologically based phenomenon in newly diagnosed celiac disease. Sci. Rep. 2022;12(1):1–10. doi: 10.1038/s41598-022-11802-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Prabakaran M., Kim S.H., Oh Y.T., Raj V., Chung I.M. Anticorrosion properties of momilactone A isolated from rice hulls. J. Ind. Eng. Chem. 2017;45:380–386. doi: 10.1016/j.jiec.2016.10.006. [DOI] [Google Scholar]

- 5.Osun T. Christian-Albrechts Universität Kiel; 2015. Impact of Agricultural Technology and Market Access on Welfare of Rice Producing Households in Nigeria. Doctoral dissertation. [Google Scholar]

- 6.Osabuohien E.S., Okorie U.E., Osabohien R.A. In: Food Systems Sustainability and Environmental Policies in Modern Economies. Obayelu A., editor. 2018. Rice production and processing in Ogun state, Nigeria: qualitative insights from farmers' association; pp. 188–215. (IGI Global). [DOI] [Google Scholar]

- 7.Chawla S., Nagal S. Sourdough in bread-making: an ancient technology to solve modern issues. Int. J. Industr. Biotechnol. Biomater. 2015;1(1):1–10. doi: 10.37628/jibb.v1i1.21. [DOI] [Google Scholar]

- 8.Olojede A.O., Sanni A.I., Banwo K., Michael T. Improvement of texture, nutritional qualities, and consumers' perceptions of sorghum-based sourdough bread made with Pediococcus pentosaceus and Weissella confusa strains. Fermentation. 2022;8(1):32. doi: 10.3390/fermentation8010032. [DOI] [Google Scholar]

- 9.Amr A., Alkhamaiseh A. Sourdough use in bread production: review. Jordan J. Agric. Sci. 2022;18:81–98. doi: 10.35516/jjas.v18i2.173. [DOI] [Google Scholar]

- 10.Banwo K., Fasuyi T.O., Olojede A.O. Potentials of Lactobacillus plantarum and Pichia kudriavzevii in co‐fermentation of sourdough from millet. Int. J. Food Sci. Technol. 2021;56(2):857–864. doi: 10.1111/ijfs.14729. [DOI] [Google Scholar]

- 11.Hu Y., Zhang L., Wen R., Chen Q., Kong B. Role of lactic acid bacteria in flavor development in traditional Chinese fermented foods: a review. Crit. Rev. Food Sci. Nutr. 2022;62(10):2741–2755. doi: 10.1080/10408398.2020.1858269. [DOI] [PubMed] [Google Scholar]

- 12.Lancetti R., Sciarini L., Pérez G.T., Salvucci E. Technological performance and selection of lactic acid bacteria isolated from argentinian grains as starters for wheat sourdough. Curr. Microbiol. 2021;78(1):255–264. doi: 10.1007/s00284-020-02250-6. [DOI] [PubMed] [Google Scholar]

- 13.Catzeddu P. Flour and Breads and Their Fortification in Health and Disease Prevention. Academic press; 2019. Sourdough breads; pp. 177–188. [DOI] [Google Scholar]

- 14.Stern A.L., Berstein J., Jones S.S., Blumberg J.B., Griffin T.S. The impacts of germinating organic wheat: effects on phytic acid, resistant starch,and functional properties of flour, and sensory attributes of sourdoughbread. Int. J. Food Sci. Technol. 2021;56(8):3858–3865. doi: 10.1111/ijfs.15002. [DOI] [Google Scholar]

- 15.Tinzl-Malang S.K., Rast P., Grattepanche F., Sych J., Lacroix C. Exopolysaccharides from co-cultures of Weissella confusa 11GU-1 and Propionibacterium freudenreichii JS15 act synergistically on wheat dough and bread texture. Int. J. Food Microbiol. 2015;214:91–101. doi: 10.1016/j.ijfoodmicro.2015.07.025. [DOI] [PubMed] [Google Scholar]

- 16.Olojede A.O., Sanni A.I., Banwo K. Rheological, textural and nutritional properties of gluten-free sourdough made with functionally important lactic acid bacteria and yeast from Nigerian sorghum. LWT--Food Sci. Technol. 2020;120 doi: 10.1016/j.lwt.2019.108875. [DOI] [Google Scholar]

- 17.Parakhina O., Lokachuk M., Kuznetsova L., Savkina O., Pavlovskaya E., Gavrilova T. Evaluation of selected lactic acid bacteria as starter cultures for gluten-free sourdough bread production. Agron. Res. 2021;19(S3):1260–1272. doi: 10.15159/AR.21.087. [DOI] [Google Scholar]

- 18.Sanusi M.S., Akinoso R., Danbaba N. Evaluation of physical, milling and cooking properties of four new rice (Oryza sativa L.) varieties in Nigeria. Int. J. Food Stud. 2017;6(2) doi: 10.1016/j.foodhyd.2020.106487. [DOI] [Google Scholar]

- 19.Ogunsakin O.A., Banwo K., Ogunremi O.R., Sanni A.I. Microbiological and physicochemical properties of sourdough bread from sorghum flour. Int. Food Res. J. 2015;22(6) [Google Scholar]

- 20.Komatsuzaki N., Izawa M., Suzumori M., Fujihara S., Shima J. The characteristics of new sourdough using lactic acid bacteria and wild yeast. J. Food Sci. Nutr. Res. 2019;2(1):1–12. doi: 10.26502/jfsnr.2642-1100004. [DOI] [Google Scholar]

- 21.AOAC . AOAC International; Maryland, U.S.A: 2005. Official Methods of Analysis, 18th Ed. [Google Scholar]

- 22.Ogunsakin A.O., Vanajakshi V., Anu-Appaiah K.A., Vijayendra S.V.N., Walde S.G., Banwo K., Prabhasankar P. Evaluation of functionally important lactic acid bacteria and yeasts from Nigerian sorghum as starter cultures for gluten-free sourdough preparation. LWT--Food Sci. Technol. 2017;82:326–334. doi: 10.1016/j.lwt.2017.04.048. [DOI] [Google Scholar]

- 23.Abedfar A., Abbaszadeh S., Hosseininezhad M., Taghdir M. Physicochemical and biological characterization of the EPS produced by L. acidophilus isolated from rice bran sourdough. LWT--Food Sci. Technol. 2020;127 doi: 10.1016/j.lwt.2020.109373. [DOI] [Google Scholar]

- 24.Santos F.G., Aguiar E.V., Rosell C.M., Capriles V.D. Potential of chickpea and psyllium in gluten-free breadmaking: assessing bread's quality, sensory acceptability, and glycemic and satiety indexes. Food Hydrocolloids. 2021;113 doi: 10.1016/j.foodhyd.2020.106487. [DOI] [Google Scholar]

- 25.Ni Q., Ranawana V., Hayes H.E., Hayward N.J., Stead D., Raikos V. Addition of broad bean hull to wheat flour for the development of high-fiber bread: effects on physical and nutritional properties. Foods. 2020;9(9):1192. doi: 10.3390/foods9091192. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Bartkiene E., Lele V., Ruzauskas M., Domig K.J., Starkute V., Zavistanaviciute P., Bartkevics V., Pugajeva I., Klupsaite D., Juodeikiene G., Mickiene R., Rocha J.M. Lactic acid bacteria isolation from spontaneous sourdough and their characterization including antimicrobial and antifungal properties evaluation. Microorganisms. 2019;8(1):64. doi: 10.3390/microorganisms8010064. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Corsetti A. Handbook on Sourdough Biotechnology. Springer; Boston, MA: 2013. Technology of sourdough fermentation and sourdough applications; pp. 85–103. [DOI] [Google Scholar]

- 28.Latou E., Mexis S.F., Badeka A.V., Kontominas M.G. Shelf life extension of sliced wheat bread using either an ethanol emitter or an ethanol emitter combined with an oxygen absorber as alternatives to chemical preservatives. J. Cereal. Sci. 2010;52(3):457–465. [Google Scholar]

- 29.Hathorn C.S., Biswas M.A., Gichuhi P.N., Bovell-Benjamin A.C. Comparison of chemical, physical, micro-structural, and microbial properties of breads supplemented with sweetpotato flour and high-gluten dough enhancers. LWT-Food Sci. Technol. 2008;41(5):803–815. doi: 10.1016/j.lwt.2007.06.020. [DOI] [Google Scholar]

- 30.Ertop M.H., Şm İ., Yilmaz F., Baltaci C., Gündoğdu A. Quality properties of wheat breads incorporated with dried sourdoughs produced with different fermentation and drying methods. Food Sci. Technol. Res. 2018;24(6):971–980. doi: 10.3136/fstr.24.971. [DOI] [Google Scholar]

- 31.Rizzello C.G., Calasso M., Campanella D., De Angelis M., Gobbetti M. Use of sourdough fermentation and mixture of wheat, chickpea, lentil and bean flours for enhancing the nutritional, texture and sensory characteristics of white bread. Int. J. Food Microbiol. 2014;180:78–87. doi: 10.1016/j.ijfoodmicro.2014.04.005. [DOI] [PubMed] [Google Scholar]

- 32.Diowksz A., Sadowska A. Impact of sourdough and transglutaminase on gluten-free buckwheat bread quality. Food Biosci. 2021;43 doi: 10.1016/j.fbio.2021.101309. [DOI] [Google Scholar]

- 33.Martín-Garcia A., Riu-Aumatell M., López-Tamames E. Influence of process parameters on sourdough microbiota, physical properties and sensory profile. Food Rev. Int. 2021:1–15. doi: 10.1080/87559129.2021.1906698. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.