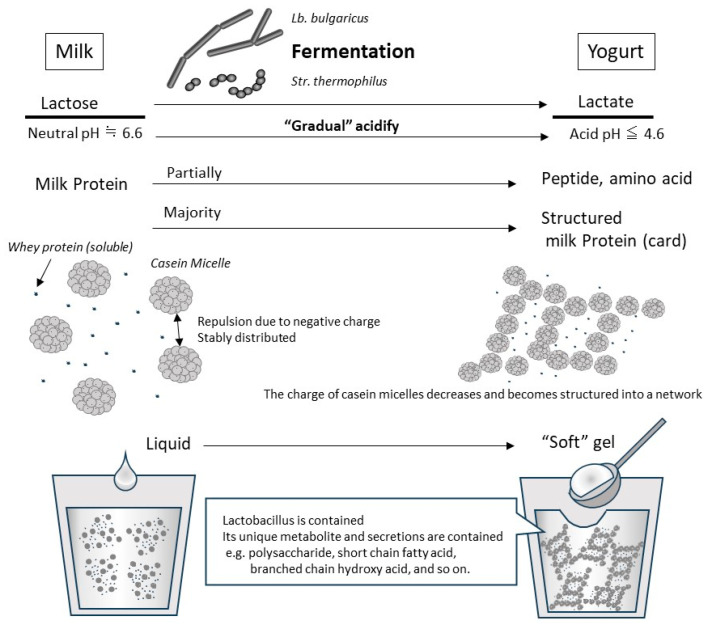

Figure 1.

Typical changes due to lactobacillus fermentation at yogurt production from milk. An illustration of the changes during the production of “set yogurt”, which is produced by the most basic method of static fermentation. When the original milk is inoculated with Lb. bulgaricus and Str. thermophilus, they grow using lactose as a carbon source. In the process, lactose is converted to lactic acid, which decreases pH gradually. In fresh milk whose pH is neutral, casein micelles are negatively charged and are stably dispersed in the liquid due to their repulsion. As the fermentation progresses and the pH drops below 5.2, the casein micelles lose their charge and coagulate with each other. However, because this acidification and aggregation occurs slowly, casein micelles become a network structure that includes whey protein and water, so they are set as a soft gel (called card). By adding steps such as shearing and draining during or after fermentation, it is possible to create yogurt with different physical properties.