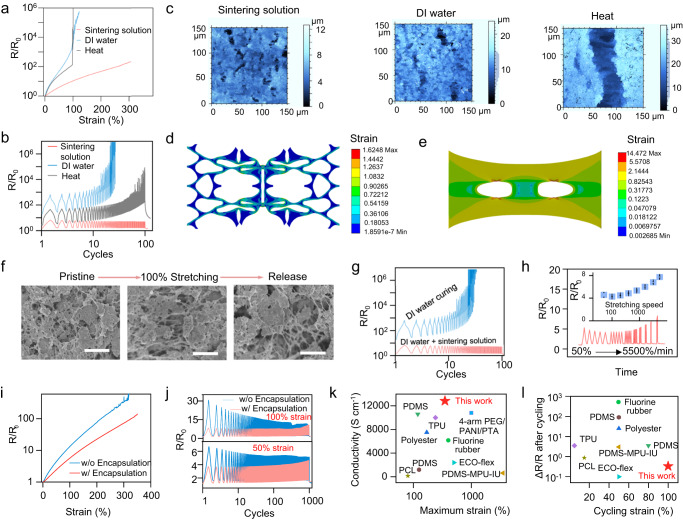

Fig. 4. The electromechanical performance of VegPU/Ag conductors.

The resistance changes upon elongation (a) and during 50% cyclic stretching (b). c The confocal images of electrodes with the presence of 100% strain; d, e the strain distribution in porous VegPU and dense VegPU with precuts upon 100% strain, respectively. f The SEM images of sintering solution-treated VegPU/Ag before, during, and after 100% stretching, scale bar: 3 µm. g The resistance changes of DI water-treated VegPU/Ag electrodes with subsequent sintering solution treatment during 50% cycling stretching. h The resistance changes of sintering solution-treated electrode at 50% cycling stretching with varied stretching speed (n = 5). i, j The resistance charges of VegPU-encapsulated VegPU/Ag electrode during single stretching and 1000 cycles stretching (50% and 100%), respectively. w/o and w/ represent without and with, respectively. The performance comparison of sustainable porous VegPU/Ag conductor with reported petrol oil-based elastomers/Ag conductors, including maximum strain–conductivity (k) at the relaxed state and cycling strain–electrical hysteresis (l). The reported conductors utilized fluorine rubber59, polyester61, PDMS62,65, TPU60, PDMS-4,4′-methylene bis(phenyl urea)-isophorone bis urea units (PDMS-MPU-IU)63, Ecoflex64, 4-arm polyethylene glycol/poly-aniline/phosphotungstic acid (4-arm PEG/PANI/PTA)66, polycaprolactone (PCL)12 as binders.