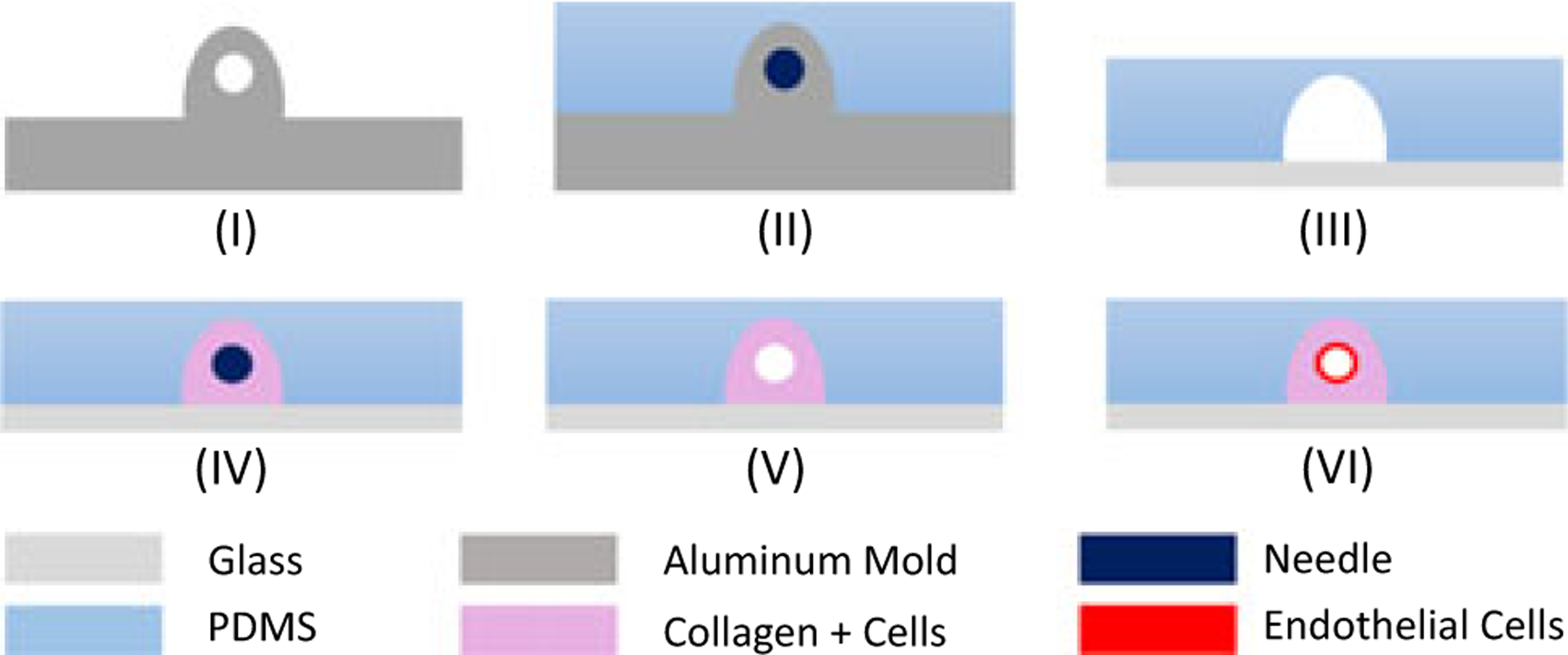

FIGURE 1.

Fabrication steps for the vascularized tissue microenvironment. PDMS was mixed with a curing agent and poured into the aluminum mold shown in (I) and baked. Inlet and outlets were patterned around a 22G or 27G needle, and housing was patterned around the aluminum extrusion shown in (II). PDMS was peeled off from the aluminum mold and bonded to the glass slide and platform shown in (III), and was treated with PEI, glutaraldehyde, and DI H2O. The same platform cavity was filled with a collagen mixture with the appropriate cell line. To form the channel to simulate the vessel, the needle was inserted (IV). Needle sizes were selected depending on desired wall shear stress. The needle was removed after polymerization of collagen (V) and preconditioned after injection of endothelium cells for 72 hr to form a vessel (VI). 3D illustration of the fabrication process is provided in the Supporting Information II. 3D: three dimension; PDMS: polydimethylsiloxane [Color figure can be viewed at wileyonlinelibrary.com]