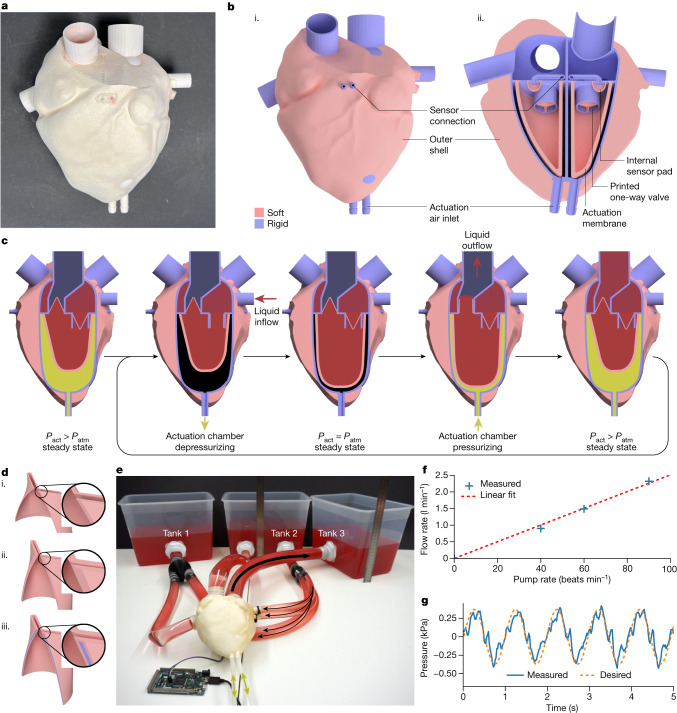

Fig. 5. Functional heart pump, printed in a single process.

a, A mammalian-heart-inspired soft-rigid hybrid pump printed in one process. Two of its four chambers are fluidically actuated and equipped with sensors. b, Illustration of the pump (i) with rigid thiol-ene parts shown in blue and soft thiol-ene parts visualized in pink. (ii) Cross section cut of the heart showing the internal sensor cavity, the position of the one-way valves, the actuation membrane and the inlet for air actuation. c, Sequential still images for the pump cycle showing a sketch of the pump’s cross section inside view. The cyclic change in actuation pressure Pact compared with atmospheric pressure Patm and the resultant liquid flow are indicated. d, Three design iterations of the printed valve. (i) A thin, soft membrane that was prone to invert on itself under pressure. (ii) A thicker membrane that was still not strong enough to avoid inversion. (iii) A functional membrane with internal, rigid reinforcement. e, Heart pump connected to three liquid tanks. This setup was inspired by the mammalian cardiovascular system. A microcontroller is used to read the sensor data and a piston setup is used to provide actuation pressure. f, The pump setup can move liquid in relation to the applied pump rate. A maximum flow rate of 2.3 l min−1 at 90 beats min−1 was measured. g, The correlation of the commanded signal to the sensed chamber pressure at 60 beats min−1.