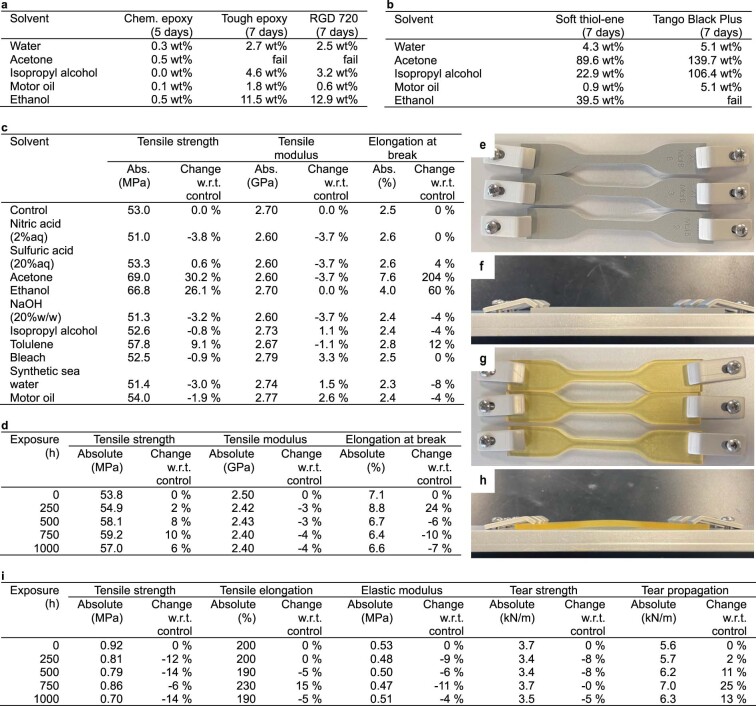

Extended Data Fig. 3. Exposure tests for printed materials.

a, Weight gain for rigid polymers under solvent exposure according to ASTM D543. b, Weight gain for soft polymers under solvent exposure according to ASTM D543. c, Change in material properties for chemically resistant epoxy after five-day submersion at 25 °C, following ASTM D543. Tests conducted following ASTM D638: Type IV, 50 mm/min, average values represented. d, Tough epoxy accelerated aging test per ASTM G154, Cycle 1 over 1000 h exposure, average values represented. Top view (e, and g) and side view (f, and h) images of material samples in the test setup for exposure according to ASTM G154, Cycle 1. Our tough epoxy material (e, and f) did not show warping compared to the state-of-the-art acrylate-based material (Stratasys RGD720) (g, and h). i, Soft thiol-ene accelerated aging test ASTM G154, Cycle 1 over 1000 h exposure. Tests conducted following ASTM D412: Die C, 500 mm/min, ASTM D624-C, and ASTM D624-B, average values represented.