Abstract

The objective of this research was to develop a nutritionally-enriched gummy jelly product incorporating nipa palm vinegar powder (NPVp; a nutrients-rich vinegar) and nipa palm syrup (NPS), a nutrients-rich sweetener with a low glycemic index. A gummy jelly product was developed based on sensory acceptance tests. The water activity and the moisture content of the final product were within the acceptable range for preservation under ambient conditions. The final product had a total phenolic content of 861 μg gallic acid equivalent (GAE) per g and an antioxidant activity (2,2-diphenyl-1-picrylhydrazyl (DPPH) inhibition) of 72.7 %. The final product had the following nutritional attributes (per 100 g dry mass): 319.7 kcal of energy, 8.8 g protein, 0.2 g fats, 70.6 g carbohydrates, 59.9 g total sugars, 0.7 g of total dietary fibers, 34.6 mg calcium, 0.3 mg iron, 168.0 mg sodium, and 774.7 mg vitamin C. The in vitro glycemic index of the product was 27.4. Based on their nutrients-content, NPVp and NPS were suitable for use in other functional food products.

Keywords: Low glycemic index food, Gummy jelly, Nipa palm syrup, Nipa palm vinegar powder

Graphical abstract

Highlights

-

•

Nipa palm (NP) sugar and vinegar were used as functional food ingredients.

-

•

Nutritionally enhanced gummy jellies could be made using NP ingredients.

-

•

The products were tasty, had good keeping quality, and antioxidant properties.

-

•

The low glycemic products were useful for delivering nutrients like vitamin C.

1. Introduction

Functional foods have become increasingly popular due to a growing awareness of the link between diet and health [1]. Gummy jelly products are particularly appealing for delivering functional ingredients because they are easy to consume, have an enjoyable texture, and can be made in diverse flavors and colors [2,3]. Ingredients such as antioxidants, fiber, vitamins, and low-glycemic sweeteners are easily incorporated into gummy jelly products to enhance their nutritional value without compromising their consumer appeal [[3], [4], [5], [6]]. Suitably formulated gummy candies can be used to control glycemic response [4].

Nipa palm (Nypa fruticans Wurmb), or mangrove palm, occurs naturally in coastal regions of South East Asia. This palm species is a source of many useful products. Nipa palm vinegar powder (NPVp), a nutrients-rich material, is a potential functional ingredient for enhancing the nutritional properties of foods [7]. Diverse health benefits have been attributed to consumption of nipa palm vinegar, including boosting immunity [8], antilipidemic activity [9], and inhibition of free radicals [10]. Nipa palm vinegar also kills pathogenic bacteria in foods [10]. Another useful product is nipa palm syrup (NPS), a nutrients-rich [11,12] natural sweetener with a low glycemic index (GI) [13,14]. NPVp and NPS can be produced from material harvested sustainably from the renewable nipa palm tree, contributing to sustainability in food production [15] and responsible consumption [16].

Although traditional gummy jelly typically has a high sugar content and a high glycemic index (GI) [4], this can be changed by using alternative natural sweeteners. This study is distinctive in incorporating NPS as a natural sweetener to create a low-GI product. Foods with low GI release glucose gradually, resulting in a lower insulin response, compared to foods with high GI [17,18]. Such low GI foods are widely recognized as healthier. A gummy jelly enriched with nutrients and formulated with nipa palm syrup, is potentially a superior alternative to conventional sugary gummy jellies. A synergistic use of nipa palm syrup and nipa palm vinegar powder to produce nutritionally enhanced gummy jellies has not been previously reported.

Antioxidants in food are known to provide numerous health benefits [19] and this has led to development of antioxidants-rich gummy jelly products [5,20,21]. Antioxidants-enriched functional foods are useful [22], as foods naturally rich in antioxidants are often consumed in limited amounts. In the present work, the naturally antioxidants-rich NPVp and NPS are combined into a nutritionally-enhanced and uniquely tasty gummy jelly product.

The present work reports on development of a tasty, nutritious, and healthy gummy jelly product based on nipa palm vinegar powder (NPVp) and the low-GI nipa palm syrup (NPS). The most palatable recipes were subjected to detailed sensory acceptance tests. The antioxidant activity, physicochemical composition, and nutritional characteristics, of the final product are reported. The developed product was characterized for storage stability under the typically used storage conditions.

2. Materials and methods

2.1. Overview of the gummy jelly production and product evaluation

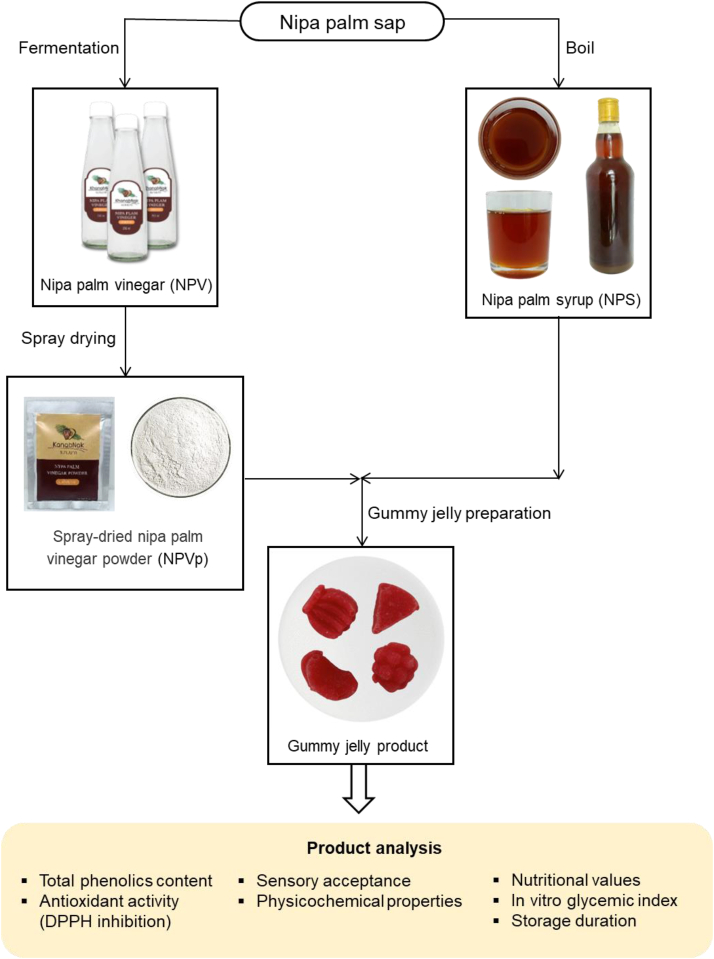

A schematic of the production of gummy jelly from nipa palm sap and the physicochemical assessment of the product, is shown in Fig. 1. Nipa palm sap was obtained from a commercial enterprise in Kanapnak sub-district (Pak Phanang district), Nakhon Si Thammarat province, Thailand. The sap was fermented to produce nipa palm vinegar (NPV) as previously described [9]. The NPV was then spray-dried to generate a nipa palm vinegar powder (NPVp) product [7].

Fig. 1.

Schematic overview of preparation and analysis of the final gummy jelly product.

The nipa palm syrup (NPS) was purchased from a local shop (Kanapnak sub-district, Pak Phanang, Nakhon Si Thammarat, Thailand) and had been produced using the traditional method of boiling the nipa palm sap until it became viscous (Fig. 1) and the total soluble solids (TSS) reached to around 70 °Brix. The NPS was allowed to cool before being packed in bottles.

NPVp and NPS were the two key ingredients used for preparing the gummy jelly product (Fig. 1). The product samples were analyzed for their total phenolics content, the antioxidant activity (DPPH inhibition), sensory acceptance, physicochemical and nutritional properties, and storage stability (Fig. 1).

2.2. Chemicals and reagents

All chemicals and reagents used were of analytical grade and purchased from Sigma-Aldrich (St. Louis, MO, USA) unless specified otherwise. Maltodextrin (DE (dextrose equivalent) = 10) was obtained from Perfect Natural Food Powder and Flavor 2002 (Thailand) Co., Ltd. (Kratumban, Samutsakorn, Thailand).

All consumable products were made using food-grade or better-quality ingredients. Hygienic practices for preparation of food were followed.

2.3. Materials

2.3.1. Spray-dried nipa palm vinegar powder

Spray-dried nipa palm vinegar powder was prepared following a published procedure [7]. First, the stabilizing agent, maltodextrin DE10 (15 % w/v; g/100 mL), was mixed with the NPV (Section 2.1). The mixture was then spray-dried using a pilot-scale spray drier with a rotary atomizer (model SDE-10, JCS Technic Line Co., Ltd., Samutsakorn, Thailand). The inlet air temperature was held at 170 °C while the outlet air temperature was maintained at 90 °C. The blower fan speed and the atomization air flow rate were fixed at 13,000 revolutions min−1 and 5 m3 h−1, respectively. After drying, the NPVp product was collected and vacuum-packed in an aluminum-laminated polyethylene bag. The product was kept at room temperature (25 °C, 75 % relative humidity) [7].

The NPVp sample was reconstituted as liquid vinegar by mixing the NPVp (6 %, or 8 % w/w; g/100 g) in water for use as the main ingredient (Table 1). The rehydrated NPVp was coded as R-NPVp. Reconstitution from a powdered material ensured a consistent concentration of the vinegar ingredients in the different batches of the product, guaranteeing uniformity in both flavor and nutritional composition.

Table 1.

Recipes of NPVp-gummy jellies (NPG).

| Recipea | Ingredients (% w/w) |

Total weight (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| NPVpb | Sucrose | Glucose syrup | Gelatin | Citric acid | Honey | Water | ||

| NPG-1 | 8.00 | 25.00 | 21.00 | 5.30 | 0.00 | 4.00 | 36.70 | 100.00 |

| NPG-2 | 8.00 | 25.00 | 21.00 | 5.30 | 0.70 | 4.00 | 36.00 | 100.00 |

| NPG-3 | 6.00 | 25.00 | 21.00 | 5.30 | 0.00 | 4.00 | 38.70 | 100.00 |

| NPG-4 | 6.00 | 25.00 | 21.00 | 5.30 | 0.70 | 4.00 | 38.00 | 100.00 |

All gummy jelly products were colored with 0.15 % v/w lemon-yellow color (Best Odor, Thailand) and flavored with 0.10 % v/w honey flavor (Chemipan, Thailand).

NPVp, Nipa palm vinegar powder.

2.4. Experiment set up

2.4.1. Production of NPVp-gummy jelly (NPG)

The NPVp was used as a main ingredient for producing NPVp-gummy jelly (NPG). Four different gummy jelly product recipes (NPG-1, NPG-2, NPG-3, and NPG-4; Table 1) were produced for initial assessments. These recipes contained the components shown in Table 1.

The NPG gummy jelly recipes were prepared by bringing to boil the mixed solutions of gelatin and glucose syrup in an electric induction cooker (Emjoi Induction Cooker, 2100W, UEIC-390, China). Then, adding sucrose, citric acid, and honey in the specified quantities. R-NPVp (Section 2.3.1) was added to the heated mixture and stirred to homogeneity. Food color (0.15 % v/w lemon-yellow food color; Best Odor, Thailand) and 0.10 % v/w honey flavor (Chemipan, Thailand) were added (Table 1). The hot mixture was then poured into molds and kept at 4 °C for 4 h to develop the shape. The NPG product was then removed from the molds and sprinkled with a mixture of cassava starch and powdered sugar (cassava starch to sugar ratio of 3:1 w/w), to prevent the jelly pieces form sticking. These gummy jelly samples were stored at 4 °C for further analysis.

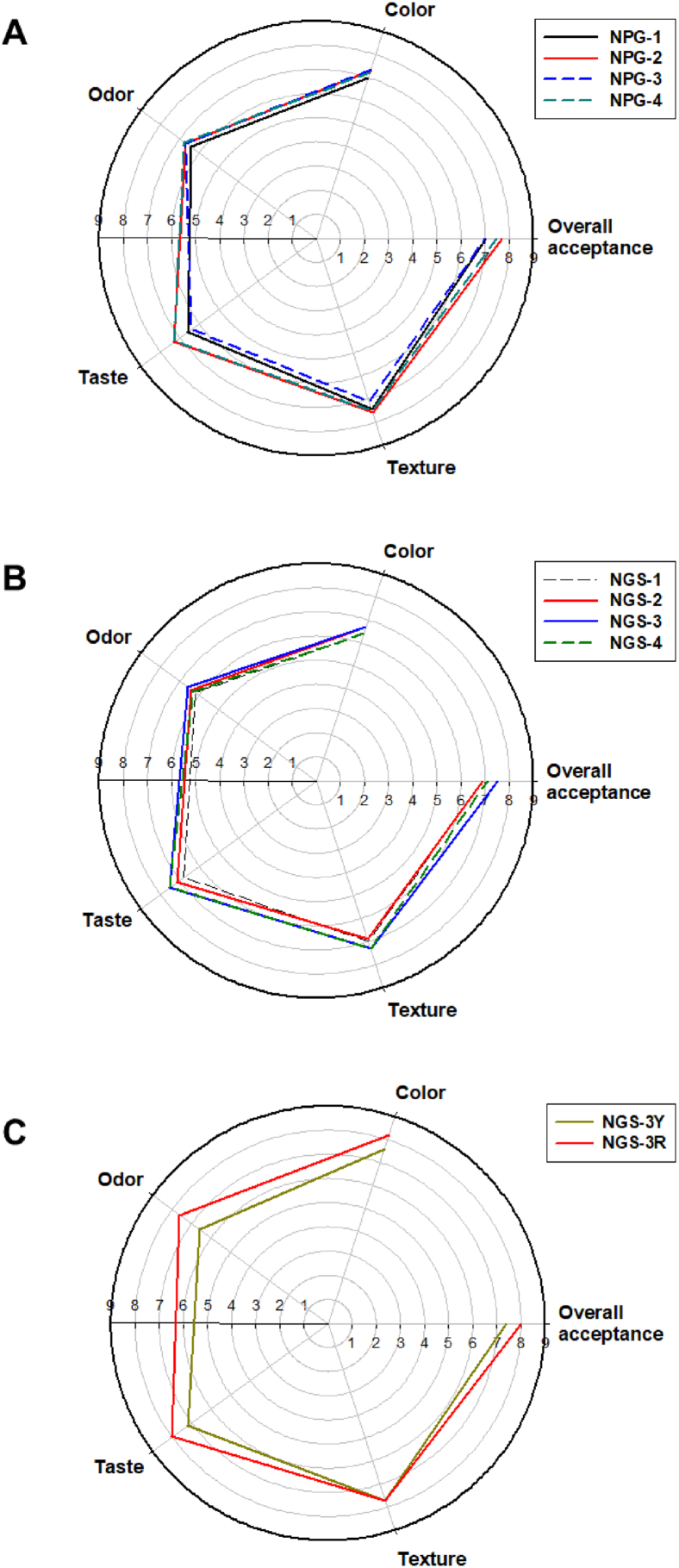

The products of all four recipes were analyzed for total phenolic content and antioxidant activity (DPPH inhibition) (Section 2.5), and subjected to sensory tests (Section 2.6, Fig. 2A). Based on the outcome of these assessments, the recipe NPG-2 was characterized as best overall, and used in subsequent experiments.

Fig. 2.

Spider charts of the sensory evaluation scores of the developed gummy jelly recipes. A 9-point hedonic scoring scale (1 = dislike extremely; 9 = like extremely) was used. (A) Sensory evaluation scores for NPVp-gummy jelly recipes NPG-1, NPG-2, NPG-3, and NPG-4, generated by 50 individuals (n = 50). (B) Sensory evaluation scores for NPVp-gummy jelly supplemented with NPS recipes NGS-1, NGS-2, NGS-3, and NGS-4, generated by 60 individuals (n = 60). (C) Sensory evaluation scores for NGS-3Y (NGS-3 supplemented with lemon-yellow color and honey flavor) and NGS-3R (NGS-3 supplemented with strawberry red color and strawberry flavor) variants of NPVp-gummy jelly supplemented with NPS, generated by 60 individuals (n = 60).

2.4.2. Production of NPVp-gummy jelly supplemented with nipa palm syrup (NGS)

The selected recipe NPG-2 (Section 2.4.1) was further developed to replace some of the glucose syrup with NPS. This effort led to products designated as NGS-1, NGS-2, NGS-3, and NGS-4 (Table 2). Vitamin C (0.5 % w/w) was added to the formulations as a nutritional supplement. In the gummy jelly recipes NGS-1 and NGS-2, the ingredients were as noted in Table 2. The recipes NGS-3 and NGS-4 had different quantities of certain components, as indicated in Table 2.

Table 2.

Recipes of NPVp-gummy jellies supplemented with nipa palm syrup (NGS).

| Recipea |

Ingredients (% w/w) |

Total weight (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| NPVpb | Sucrose | NPSc | Gelatin | Citric acid | Honey | Vitamin C | Water | ||

| NGS-1 | 8.00 | 21.00 | 24.00 | 5.30 | 0.70 | 4.00 | 0.50 | 36.50 | 100.00 |

| NGS-2 | 8.00 | 21.00 | 24.00 | 5.60 | 0.70 | 4.00 | 0.50 | 36.20 | 100.00 |

| NGS-3 | 8.00 | 20.00 | 21.00 | 5.30 | 0.70 | 4.00 | 0.50 | 40.50 | 100.00 |

| NGS-4 | 8.00 | 20.00 | 21.00 | 5.60 | 0.70 | 4.00 | 0.50 | 40.20 | 100.00 |

All gummy jelly products were colored with 0.15 % v/w lemon-yellow color (Best Odor, Thailand) and flavored with 0.10 % v/w honey flavor (Chemipan, Thailand).

NPVp, Nipa palm vinegar powder.

NPS, Nipa palm syrup.

All products were analyzed for total phenolics content and antioxidant activity (DPPH inhibition) (Section 2.5; Table 3) and subjected to sensory evaluations (Section 2.6, Fig. 2B). Based on sensory assessment, the recipe NGS-3 (Table 2) was selected and supplemented with 0.15 % v/w strawberry red color and 0.1 % v/w strawberry flavor, to produce the red recipe NGS-3R (Table 4).

Table 3.

The total phenolic content (TPC) and the antioxidant activity (DPPH inhibition) of the developed gummy jellies.

| Recipe | TPC (μg GAE g−1 sample)a,b | DPPH inhibition (%)a,b |

|---|---|---|

| NPVp-gummy jelly (NPG) | ||

| NPG-1 | 160.52 ± 3.48b | 23.75 ± 1.64b |

| NPG-2 | 300.44 ± 2.74a | 37.19 ± 1.02a |

| NPG-3 | 155.70 ± 2.01b | 20.88 ± 1.79b |

| NPG-4 | 288.16 ± 4.74a | 35.22 ± 1.88a |

| NPVp-gummy jelly supplemented with nipa palm syrup (NGS) | ||

| NGS-1 | 881.99 ± 9.00ab | 73.00 ± 0.88a |

| NGS-2 | 887.35 ± 10.98ab | 73.20 ± 0.37a |

| NGS-3 | 861.07 ± 10.25bc | 72.67 ± 0.55a |

| NGS-4 | 853.53 ± 6.94c | 72.62 ± 0.22a |

Abbreviations: DPPH, 2,2-diphenyl-1-picrylhydrazyl radical; TPC, total phenolic content; GAE, gallic acid equivalent.

Different superscript lowercase letters within a column indicate a significant difference (p < 0.05).

Each treatment was analyzed in triplicate.

Table 4.

Formulation of NPVp-gummy jelly (NPG) and NPVp-gummy jelly supplemented with nipa palm syrup (NGS).

| Ingredientsa | Recipe |

|

|---|---|---|

| NPG-2b | NGS-3Rc | |

| NPVp (%, w/w) | 8.00 | 8.00 |

| NPS (%, w/w) | – | 21.00 |

| Sucrose (%, w/w) | 25.00 | 20.00 |

| Glucose syrup (%, w/w) | 21.00 | – |

| Gelatin (%, w/w) | 5.30 | 5.30 |

| Citric acid (%, w/w) | 0.70 | 0.70 |

| Honey (%, w/w) | 4.00 | 4.00 |

| Vitamin C (%, w/w) | – | 0.50 |

| Water (%, w/w) | 36.00 | 40.50 |

| Total weight (g) | 100.00 | 100.00 |

NPVp, nipa palm vinegar powder; NPS, nipa palm syrup.

NPG-2, NPVp-gummy jelly recipe 2 (with 0.15 % v/w lemon-yellow color and 0.1 % v/w honey flavor additives).

NGS-3R, NPVp-gummy jelly incorporated with NPS and vitamin C recipe 3 (with 0.15 % v/w strawberry red color and 0.1 % v/w strawberry flavor additives).

2.4.3. Effects of food color and flavor

The impact of color and flavor on consumer preference of gummy jelly was assessed using the basic recipe NGS-3 gummy jelly (Table 2). In separate preparations of NGS-3, the following food colors and flavors were used: 0.15 % v/w of lemon-yellow, or strawberry red (Winner's, Thailand) and 0.10 % v/w of honey flavor, or strawberry flavor (Winner's, Thailand). The identification codes for the differently colored products were NGS-3Y (lemon-yellow color and honey flavor) and NGS-3R (strawberry red color and strawberry flavor) (Section 2.6, Fig. 2C).

2.4.4. The storage stability

For storage stability assessment, the gummy jelly samples NPG-2 (Table 4, Fig. 3A) and NGS-3R (Table 4, Fig. 3B) were separately packed in aluminum foil-lined plastic zip lock bags and stored at 25 °C for 30 days. Entire bags were sampled at 30 days for analysis. Each sample (10 g) was enumerated for yeasts and molds by using standard methods [23,24].

Fig. 3.

The developed gummy jelly products: NPVp-gummy jelly recipe 2 (NPG-2, A); NPVp-gummy jelly supplemented with NPS recipe 3 with strawberry red color and strawberry flavor (NGS-3R, B).

2.5. Total phenolic content and the antioxidant activity

The total phenolic content of the gummy jelly samples was determined using the method of Chatatikun and Kwanhian [9], with gallic acid as the reference standard. A sample extract was prepared as follows: gummy jelly (1 g) was mixed with 10 mL of MeOH/water (80:20, v/v) and left for 24 h at 4 °C. This mixture was centrifuged (5465×g, 4 °C, 10 min) (Sorvall Biofuge Stratos, Heraeus; www.thermoscientific.com). An aliquot (20 μL) of the supernatant was mixed with 100 μL of Folin-Ciocalteu reagent and 80 μL of sodium carbonate solution (75 g L−1). The absorbance was measured at 765 nm after 30 min of incubation at room temperature. Gallic acid solutions (31.25, 62.5, 125, 250, and 500 μg mL−1) were treated the same way as the extract of the sample and the measured absorbance values were used to generate a calibration plot. The linearity of the calibration plot was confirmed by the high value of its regression coefficient (R2 = 0.993). The total phenolic content was determined as μg gallic acid equivalent per g (μg GAE g−1) sample.

The antioxidant activity was measured as the 2,2-diphenyl-1-picrylhydrazyl (DPPH⋅) radical-scavenging activity, using a slight modification of a published method [5,25]. A 20 μL aliquot of the sample extract was mixed with 980 μL of 0.3 mM DPPH solution (prepared in methanol). The mixture was shaken and placed in a dark chamber for 30 min. The absorbance was measured at 517 nm using a microplate reader (UV-2401 PC spectrophotometer, Shimadzu, Kyoto, Japan) against a blank of the DPPH solution without the sample extract. The calibration curve was prepared using various concentrations of vitamin C (20–100 μg mL−1).

The DPPH⋅ radical-scavenging activity (%) was calculated using the following equation:

| (1) |

where Ab was the absorbance of the blank and As was the absorbance of the gummy jelly extract treated as above.

2.6. Sensory testing

Human panelists did the sensory testing. The testing had been approved by the Ethics Committee in Human Research, Walailak University, Thailand (approvals WUEC-21-169-01 dated July 20, 2021, and WUEC-22-243-01 dated August 16, 2022).

A 3-part sensory evaluation was performed. In the first part, the effects of two NPVp doses (6 %, or 8 % w/w) and two citric acid concentrations (0 %, or 0.7 %, w/w) on the properties of the gummy jelly recipes NPG (NPG-1, NPG-2, NPG-3, and NPG-4; Table 1) were assessed using a nontrained panel of 50 individuals. The panelists were provided with the gummy jelly placed on white plastic plates, each bearing a different three-digit code of random numbers. The samples were served with a glass of water and before testing a sample, the panelists washed their mouths with water. The panelists evaluated the color, odor, taste, texture, and overall acceptance of the samples. The panelists scored each attribute of the sample on a 9-point scale [3] (Fig. 2A) (see Supplementary Material; Questionnaire for sensory evaluation of recipes NPG-1 to NPG-4).

In the second part of sensory evaluation, the panel comprised of 60 nontrained individuals. The samples had been prepared using a selected NPVp dose (8 % w/w), the NPS added at one of two doses (21 %, or 24 % w/w), and vitamin C added (0.5 % w/w). The samples contained different levels of sucrose (20 %, or 21 % w/w) and gelatin (5.3 %, or 5.6 % w/w). The panelists rated the four gummy jelly products (NGS-1, NGS-2, NGS-3, and NGS-4; Table 2) in terms of the earlier specified attributes using the above-mentioned 9-point scale (Fig. 2B) (see Supplementary Material; Questionnaire for sensory evaluation of recipes NGS-1 to NGS-4).

In the third part of sensory evaluation, the two gummy jelly recipes, NGS-3Y and NGS-3R, were presented to 60 panelists to obtain their judgment on product attributes (Fig. 2C) (see Supplementary Material; Questionnaire for sensory evaluation of recipe NGS-3Y and NGS-3R).

2.7. Moisture content and water activity

The moisture content of the gummy jelly products was measured according to AOAC Method 950.46 [26].

The water activity (aw) was determined using an Aqualab Series 3 TE aw meter (Decagon, Pullman, WA, USA) with an accuracy of 0.003. The gummy jelly sample was placed in the sample holder to perform the measurements. Measurements were made in triplicate, at 25 °C, after 3 min of an stabilization period [3].

2.8. Color analysis

The developed gummy jellies' color parameters (L*, a*, and b*) were measured using the Hunterlab/ColorFlex EZ Spectrophotometer (10° standard observer, illuminant D65; Hunter Associates Laboratory, Reston, VA, USA). The device had been calibrated to a white and black standard. For the measurements, a gummy jelly sample was placed on the clear plastic plate of the instrument and the color parameters L*, a*, and b* were recorded [3].

2.9. Texture analysis

Textural characteristics of the developed gummy jellies were quantified using a texture analyzer (TA-XTplus, Stable Micro Systems Co. Ltd., Surrey, UK). Samples (1 × 1 × 0.5 cm) were cut from 10 randomly selected gummy jellies. The tests were performed at 25 °C. All refrigerated (4 °C) gummy jellies were equilibrated to the test temperature before testing. For texture analysis test, the samples were penetrated by a cylindrical probe (35 mm diameter). The analyzer speed settings were as follows: a pre-speed of 1 mm s−1, a test-speed of 5 mm s−1, and a post-speed of 5 mm s−1. The distance was set to 75 % strain, and the trigger force was 5 g. Hardness, springiness, cohesiveness, and chewiness were recorded by the instrument's software [27].

2.10. Nutritional profile

The nutritional profiles of the nipa palm syrup and the gummy jelly products were examined using the following AOAC [26] methods: ash (Method 923.03), protein (Method 981.10), fat (Method 948.15), cholesterol (Method 976.26), total dietary fiber (Method 985.29), total sugar (Method 925.35), calcium (Ca), sodium (Na), and iron (Fe) (Method 984.27). The calorie content and total carbohydrates were determined using the method of Sullivan and Carpenter [28].

The amounts of vitamin A (retinol), vitamin B1 (thiamin), vitamin B2 (riboflavin), and vitamin C (ascorbic acid) were quantified using adaptations of the published methods [29].

The glycemic index of the developed gummy jelly samples was determined using an adaptation of a published method [30].

2.11. Statistical analysis

The data are presented as the mean values (± standard deviation) from three independent replicates. One-way ANOVA and Tukey's test were used to evaluate the data in Table 3. The independent samples t-test was used compare the relevant data in Table 5 and Table 6. The paired t-test was utilized for data analysis in Table 7. In all instances, a p-value of <0.05 was considered statistically significant.

Table 5.

Physicochemical properties of the developed gummy jelly products (recipes NPG-2 and NGS-3R).

| Parameter | Unit | NPG-2a | NGS-3Rb |

|---|---|---|---|

| Water activity | – | 0.73 ± 0.00§ | 0.67 ± 0.00§ |

| Moisture | % (w/w) | 20.63 ± 0.85n | 19.32 ± 0.20n |

| Color | |||

| L* | – | 57.18 ± 1.15n | 55.98 ± 0.76n |

| a* | – | 5.21 ± 0.21§ | 20.93 ± 1.28§ |

| b* | – | 52.35 ± 1.45§ | 8.00 ± 0.53§ |

| Texture | |||

| Hardnessc | N | 95.59 ± 3.10n | 94.74 ± 3.93n |

| Cohesivenessd | – | 0.89 ± 0.04n | 0.70 ± 0.03n |

| Springinesse | mm | 0.94 ± 0.04n | 0.91 ± 0.07n |

| Chewinessf | N mm | 80.21 ± 2.72n | 60.56 ± 6.74n |

| Gumminessg | N | 85.07 ± 2.08n | 66.32 ± 2.70n |

Results are mean values ± standard deviations of the selected pieces of the same final product. Within the same row, the superscript § denotes significant differences (p < 0.05), and n indicates a nonsignificant difference (p ≥ 0.05), as determined by the independent samples t-test.

NPG-2, NPVp-gummy jelly recipe 2 (with 0.15 % v/w lemon-yellow color and 0.1 % v/w honey flavor additive).

NGS-3R, NPVp-gummy jelly incorporated with NPS and vitamin C recipe 3 (with 0.15 % v/w strawberry red color and 0.1 % v/w strawberry flavor additive).

Hardness, the force required to compress the material by a given amount [31].

Cohesiveness, the strength of the internal bonds in the sample [31].

Springiness, the elastic recovery that occurs when the compressive force is removed [31].

Chewiness, the energy required to chew a solid food into a state ready for swallowing [31].

Gumminess = Hardness × Cohesiveness, the energy required to break down a semi-solid food ready for swallowing [31].

Table 6.

Nutritional analysis of nipa palm syrup (NPS), the NPVp-gummy jelly recipe 2 (NPG-2), and the NPVp-gummy jelly supplemented with NPS recipe 3, with strawberry red color and strawberry flavor (NGS-3R).

| Component or characteristic | Unit/100 ga,b | NPS | Recipe NPG-2d | Recipe NGS-3Rd |

|---|---|---|---|---|

| Energy | kcal | 291.5 ± 1.0 | 311.7 ± 0.6§ | 319.7 ± 0.5§ |

| Protein | g | 1.21 ± 0.01 | 0.78 ± 0.02§ | 8.84 ± 0.16§ |

| Fat | g | 0.14 ± 0.00 | 0.66 ± 0.01§ | 0.22 ± 0.00§ |

| Cholesterol | mg | Not detected | Not detected | Not detected |

| Carbohydrate | g | 71.35 ± 0.35 | 75.66 ± 0.22§ | 70.60 ± 0.90§ |

| Total dietary fiber | g | 0.39 ± 0.00 | 0.88 ± 0.00§ | 0.73 ± 0.00§ |

| Total sugars | g | 67.11 ± 0.52 | 38.46 ± 0.32§ | 59.89 ± 0.95§ |

| Ash | g | 2.21 ± 0.01 | 0.27 ± 0.00§ | 1.02 ± 0.01§ |

| Minerals | ||||

| Sodium (Na) | mg | 348.63 ± 0.20 | 55.58 ± 0.10§ | 167.98 ± 0.30§ |

| Calcium (Ca) | mg | 29.57 ± 0.31 | 17.59 ± 0.14§ | 34.58 ± 0.03§ |

| Iron (Fe) | mg | 0.12 ± 0.00 | 0.26 ± 0.00§ | 0.33 ± 0.00§ |

| Vitamins | ||||

| Vitamin A (retinol) | μg | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 |

| Vitamin B1 (thiamin acid) | mg | Not detected | Not detected | Not detected |

| Vitamin B2 (riboflavin) | mg | Not detected | Not detected | Not detected |

| Vitamin C (ascorbic acid) | mg | Not detected | 0.59 ± 0.00§ | 774.72 ± 0.82§ |

| Other characteristics | ||||

| DPPH inhibition (%) | % | – | 37.2 ± 1.0§ | 72.7 ± 0.6§ |

| TPC | μg GAE g−1 | – | 300.4 ± 2.7§ | 861.1 ± 10.3§ |

| In vitro glycemic index (GI)c | – | 22.1 | – | 27.4 |

One sample of each of the final gummy jelly product was analyzed in triplicate. Data are average values ± standard deviations.

Dry weight basis.

Measured as in Phimolsiripol et al. [30].

Each nutritional characteristic of Recipe NPG-2 and Recipe NGS-3R was statistically compared: in the same row, the superscript § signifies significant differences (p < 0.05) as determined by the independent samples t-test.

Table 7.

The gummy product recipe NPG-2 and recipe NGS-3R after storage at 25 °C for 30 days.

| Recipe | Appearance | Moisture |

Water activity |

Color |

Molds |

Yeasts |

||

|---|---|---|---|---|---|---|---|---|

| (% w/w) | – | L* | a* | b* | CFU g−1 | CFU g−1 | ||

| NPG-2δ |  |

20.67 ± 0.01n | 0.73 ± 0.00n | 57.04 ± 0.05n | 5.22 ± 0.06n | 52.44 ± 0.15n | 00.00 ± 0.0 | 00.00 ± 0.00 |

| NGS-3Rδ |  |

19.61 ± 0.01n | 0.69 ± 0.01nn | 55.94 ± 0.05n | 20.72 ± 0.03n | 8.04 ± 0.07n | 00.00 ± 0.00 | 00.00 ± 0.00 |

Data represent mean values ± standard deviations. All measurements were in triplicate.

δ The measured data shown for the Recipe NPG-2 and Recipe NGS-3R were not significantly different (n) from initial values (Day 0) at 25 °C (paired t-test, p ≥ 0.05).

3. Results and discussion

3.1. Effects of NPVp and citric acid on the gummy jelly product

The NPVp served as the main functional component in the gummy jellies. The NPVp had been prepared from nipa palm sap as previously described [7]. The four formulations of NPVp-gummy jellies (NPG-1, NPG-2, NPG-3, and NPG-4; Table 1) varied only in the concentrations of NPVp (6 % or 8 % w/w) and citric acid (0 % or 0.7 % w/w). An optimal recipe was chosen based on its high total phenolic content (TPC), high antioxidant activity (DPPH inhibition), and high sensory acceptance score.

The total phenolic content and antioxidant activity of the products are shown in Table 3. The two products with the highest levels of total phenolics were NPG-2 and NPG-4 and the same two products displayed the highest antioxidant capacity (Table 3). Both these products contained citric acid in addition to NPVp. NPVp in the absence of citric acid (products NPG-1, NPG-3) did not result in high levels of total phenolics or a high antioxidant activity in the products. Pure citric acid does not have any phenolics. Therefore, enhancement of the phenolics content in products containing citric acid was a consequence of its reaction with some of the components of NPVp. Thus, the product that combined the highest level of NPVp with citric acid (i.e., product NPG-2) had the most total phenolics and also the highest antioxidant capacity among the NPG products (Table 3). NPVp contained phenolic compounds [7] and was therefore a direct source of these compounds in the NPG products, but its concentration alone could not explain the observed phenolics levels in the four NPG products. In studies with entirely different products such as wheat sprouts [32] and fruity jelly candies containing propolis extract [33], supplementation with citric acid has enhanced the total phenolics content.

The antioxidant capacity of the NPG products correlated directly with their total phenolics content (Table 3). In other work, presence of fruit purees in gummy jelly has enhanced DPPH inhibition capacity of the product [34]. In jelly candies based on pomegranate juice, antioxidant activity could be enhanced by supplementing with 1 % citric acid [33].

The sensory assessments of gummy jelly product recipes NPG-1, NPG-2, NPG-3, and NPG-4 by the 50 panelists are summarized in Fig. 2A. The recipe NPG-2 received the highest overall acceptance score of 7.7 ± 1.1 (Fig. 2A). Its scores for specific attribute were: 7.3 ± 1.3 for color, 6.7 ± 1.6 for odor, 7.3 ± 1.7 for flavor, and 7.6 ± 1.4 for texture (Figs. 2A and 3A). The two recipes without citric acid (i.e., NPG-1 and NPG-3) had noticeably lower scores for taste and overall acceptance compared to the two products that had citric acid (i.e., NPG-2 and NPG-4) (Fig. 2A). Thus, citric acid enhanced two important sensory attributes of the gummy jelly [3,33]. The best recipe was NPG-2 in terms of overall acceptance. The physicochemical properties of NPG-2 were characterized in detail (Table 5) and it became the basis for further experiments.

3.2. Effects of NPVp, NPS, and vitamim C on the gummy jelly product

To further develop the gummy jelly by incorporating NPS and vitamin C, the concentration of NPVp (8 % w/w), citric acid (0.7 % w/w), and honey (4 % w/w) in the formulations were fixed at the same level as in NPG-2 (Table 1), but vitamin C (0.5 % w/w) was added to all new recipes, and they had the other components at following different levels: NPS (21 %, or 24 % w/w), sucrose (20 %, or 21 % w/w), and gelatin (5.3 %, or 5.6 % w/w). This led to the four recipes NGS-1, NGS-2, NGS-3, and NGS-4 (Table 2). These recipes ranged from around 853 to nearly 887 μg GAE g−1 sample, in terms of their total phenolics content (NGS recipes; Table 3), although the total phenolics in NGS-1, NGS-2, and NGS-3 were not significantly different. The DPPH inhibition values of all NGS recipes were nearly the same at ∼73 % (NGS recipes; Table 3). The addition of NPS as a sweetener and vitamin C as a nutrient resulted in the NGS recipes having significantly increased values of total phenolics and antioxidant activity (DPPH inhibition) compared to the NPG recipes. Depending on the NGS recipe, NPS contributed around 17–44 mg GAE/100 g of phenolics to the recipe [12] and vitamin C, a known antioxidant, contributed to enhancing DPPH inhibition relative to NPG recipes. Literature evidence suggests the phenolic compounds in combination with vitamin C synergistically boost the antioxidant capacity compared to the same quantity of phenolics alone [35,36].

A sensory investigation was conducted with a new set of 60 untrained individuals to assess potential acceptability of the gummy jellies NGS1–4 (Table 2). The results of the sensory assessment are shown in Fig. 2B. The amount of NPS and sucrose was higher in the products NGS-1 and NGS-2 compared to the products NGS-3 and NGS-4 (NGS1–4; Table 2), therefore, they were overly sweet, reducing their consumer acceptance (Fig. 2B). Use of NPS may have had some effect on product acceptability, because NPS imparted a darker color to the products and contributed an enhanced caramel flavor, a consequence of the Maillard reaction and characteristic caramelization that occurred in making of the nipa palm syrup from the sap (Fig. 1) [13]. Despite these factors, the panelists gave high overall acceptability scores to all NGS recipes, but the NGS-3 was the most well-liked. For this product, the sensory scores (Fig. 2B, NGS-3) were as follows: 6.7 ± 1.4 for color; 6.6 ± 1.5 for odor; 7.5 ± 1.3 for taste; 7.3 ± 1.0 for texture; and 7.5 ± 0.9 for overall acceptance.

3.3. Effects of food colors and flavors

The best recipe, i.e., the NGS-3, developed in the previous section was further enhanced by improving the appearance by including food colors and flavors. Thus, two NGS-3 variants were developed. These were a lemon-yellow colored product with a honey flavor, designated as NGS-3Y, and a red strawberry colored product with strawberry flavor, designated as NGS-3R (Table 4, Fig. 3B). The 60 panelists assessed the textures of both products to be statistically comparable, but in terms of color, odor, and overall approval they rated the red product (i.e., NGS-3R) to be distinctly (p < 0.05) more attractive (Fig. 2C). The sensory scores for the NGS-3R were: 8.2 ± 1.0 for color; 7.6 ± 1.2 for odor; 8.0 ± 1.0 for taste; 7.7 ± 1.5 for texture; and 8.0 ± 0.9 for overall acceptance (Fig. 2C, NGS-3R).

3.4. Physicochemical properties

The water activity values of the gummy jelly NPG-2 and NGS-3R products were 0.73 and 0.67, respectively (Table 5). These values were close to a water activity of 0.70 reported for other gummy jellies [21]. The water activity of soft candy products generally ranges from 0.45 to 0.75 [2,37]. These low water activities effectively prevent microbial growth on, or within, the product [2,37].

The moisture content of NPG-2 and NGS-3R (19–21 %; Table 5) was not significantly different, and it was within the 18–25 % range reported for other gummy jellies [6,25], although some gummy jelly products may have a moisture content as high as 42 % [27] and as low as 10 % [38]. The mouthfeel and handling attributes of gummy products correlate with their moisture content: products with a low moisture content tend to be harder to chew, whereas too much moisture results in a sticky product [2].

The L*, b*, and a* color parameters of the products NPG-2 and NGS-3R are shown in Table 5. In terms of the lightness L*, measured on a scale of 0 (black) to 100 (white), both products tended to be a little towards dark (Table 5). The a* and b* values of the two products differed significantly (Table 5): the product NGS-3R with a red strawberry color, had an a* value of nearly 21 whereas the lemon-yellow product NPG-2 had an a* value of around 5 (Table 5). This was consistent with expectations, as the parameter a* indicated color in the red-green spectral range [3] and a high a* was indicative of a color tending more towards red than green, whereas a low a* was indicative of a color tending towards green. The color parameter b* was also quite different for the two products: the product NPG-2 with its bright yellow coloration had a much higher b* (∼52, Table 5) compared to the red colored product NGS-3R (b* = 8) (Table 5). This agreed with expectations, as the parameter b* indicated a value in the yellow-blue spectral range [3] and therefore NPG-2 had a much higher b* compared to the red product NGS-3R. The appearance of the two products is shown in Fig. 3.

The texture of gummy jelly product affects its mouthfeel [3]. Texture is influenced by numerous factors, including the production process, and the amounts of water, sugar, lipids, air, and other components in the product [2].

In terms of hardness, both products were quite similar with hardness values of around 95 N (Table 5). For similar products containing gelatin and pectin, hardness values have previously been reported to be in the range of 89.6–106.1 N [27], in keeping with the data in the present work on gummy jellies. Both products had a gelatin content of 5.3 % (Table 4) that was comparable to a typical gelatin content of between 5.0 and 5.5 % in gummy jellies [38].

The product cohesiveness is a measure of the strength of its internal linkages [39]. Both the gummy jelly products had cohesiveness values (0.70–0.89; Table 5) that were not significantly different, suggesting that the changes in composition within the limits used (Table 4) did not substantially affect the internal networks in these products. This was consistent with other similar reports [4,40].

The springiness is a measure of elasticity of a product. Both NPG-2 and NGS-3R were similar in springiness with no significant difference, although NPG-2 was a little springier (Table 5). Both products were somewhat more springy compared to similar products in the literature that have been reported to range in springiness from 0.73 to 0.84 [27].

Chewiness is the amount of energy required for masticating solid food to prepare it for swallowing [31]. The product NPG-2 was chewier than the product NGS-3R (Table 5), although the difference was not significant. This difference in chewiness was associated with the much higher content of sucrose and glucose in NPG-2 compared to NGS-3R. In gummy sweets and other products, presence of glucose suppresses crystallization of sucrose [2,41,42], allowing more of it to remain in solution and this contributes to chewiness.

Gumminess is defined as the product of cohesiveness and hardness [31]. The sample NPG-2 had a substantially higher gumminess than the sample NGS-3R mainly because of the higher cohesiveness of the former (Table 5). Both the gummy jellies had higher gumminess values compared to the range of 42.4–58.8 N typical for gummies [27]. However, the textural characteristics of gummy jellies depend on the product and there are no particular optimal attributes for them [3,6,27].

3.5. Nutritional characteristics

Nutritional values for the nipa palm syrup (NPS), and the gummy products NPG-2 and NGS-3R, are shown in Table 6. The measured data for nipa palm syrup (Table 6) were generally comparable to the literature data [12]. The measured energy content (Table 6) was around 77.5 % of the lower value in the previously reported range (376–413 kcal per 100 g [12]); the protein content was around 60.5 % of the lower value in the earlier reported range (2.0–2.9 g protein per 100 g [12]), the total carbohydrate content was 76.8 % of the lower value in the earlier reported range (92.9–94.2 g carbohydrate per 100 g [12]), the total sugars were 72.1 % of the lower value in the earlier reported range (93.1–93.6 g per 100 g [12]). Except for calcium, the minerals content of NPS in the present work were generally lower, or comparable, to the values reported in the literature. The calcium content was around 49-fold more than the higher value in the literature-reported range (0.3–0.6 mg calcium per 100 g [12]), the iron content was 80 % of the lower value in the literature reported range (0.15–0.23 mg iron per 100 g [12]), and the sodium content was around 2.5 % higher than the lower value in the literature reported range (340–474 mg sodium per 100 g [12]). NPS is a natural product and its composition can vary a lot depending on the palm cultivar, the production process, the soil conditions, the local climate, the season, as well as other possible factors [12,13].

Relative to the product NPG-2, the product NGS-3R had been fortified with NPS and vitamin C (Table 4). This fortified product contained around 2.6 % more calories than the product NPG-2, but had nearly 11-fold more protein, nearly 67 % less fat, ∼7 % less carbohydrate, ∼56 % more total sugars, and 17 % less fiber (Table 6). The fortified product had higher minerals content (Na, Ca, Fe) than did NPG-2 (Table 6). The fortified product contained 774 mg of vitamin C per 100 g (Table 6); therefore, consumption of just 10 g of this product (equivalent to about 4 pieces in a typical commercial packet of gummy jellies) would provide 77.4 mg of vitamin C to an individual. This compares favorably with a 70 mg recommended daily dose of this vitamin for adult males and a 75 mg recommended daily does for adult women. Consuming more than a few pieces of the gummy jelly would not harm, as too much vitamin C does no harm, and the upper daily limit on its intake may be as high as 2000 mg. The antioxidant capacity of the fortified product NGS-3R was nearly 2-fold that of the product NPG-2 (DPPH radial inhibition; Table 6) and the fortified product had a nearly 3-fold higher content of phenolics compared to the product NPG-2. Clearly, the nutritional value of NGS-3R was greatly enhanced by inclusion of NPVp, NPS, and vitamin C in its formulation. The two gummy jelly products differed significantly (p < 0.05) in terms of all their nutritional attributes (Table 6).

The glycemic index (GI) of a food indicates how rapidly the carbohydrates in it raise the blood glucose level [43,44]. Foods with a GI of less than 55 are considered as low-GI foods whereas those with a GI value between 55 and 70 are classified as medium-GI foods. The GI value of high-GI foods exceeds 70 [18,45]. Patients with Type 2 diabetes are better able to regulate their blood glucose level using low-GI foods compared to high-GI diets [46]. Based on measured data (Table 6), the product NGS-3R could be classified among the low-GI food products.

The NPS had a glycemic index (GI) of 22.1, whereas the NPS-containing gummy jelly product NGS-3R had a comparable GI of 27.4 (Table 6). Sweeteners derived from various palms have generally been reported to have relatively low GI values, comparable to the data measured for NPS and NGS-3R in the present work. The reported GI values of products such as palm sugar, coconut sugar and coconut syrup, have been in the range of 35–42 [14]. For comparison, the GI of glucose is 100 whereas that of sucrose is 68. The relatively low GI of NPS and other palm sweeteners suggests that the sugars in these products occurred in the form of natural complexes with materials such as fiber [13]. This apparently slows sugar release in the digestive tract.

The United States Department of Agriculture (USDA) has published the following typical nutritional data for commercial gummy jellies (per 100 g) [47,48]: 333 kcal of energy, 77.8 g of carbohydrates including 55.6 g of added sugar and unknown quantities of protein, minerals, and vitamins [47]. For commercial gummies with fruit puree, USDA has published the following nutritional data (per 100 g): 290 kcal of energy, 80.6 g of carbohydrates including 48.4 g of added sugar, 12.9 g of fiber, and 226 mg of sodium [48]. Compared to these data for commercial gummy products, the product NPG-2 had less total sugars (Table 6). In contrast, the product NGS-3R was higher in total sugars, but still had a sufficiently low GI to qualify as a low-GI food (Table 6).

3.6. Product stability during storage

The appearance and other stability attributes of the gummy jellies NPG-2 and NGS-3R after storage for 30 days at 25 °C, are shown in Table 7. In terms of the electronic color parameters L*, a*, and b*, the colors of both products showed a slight change after storage compared to the freshly made product samples (Table 5). However, these differences were not significant as indicated in Table 7, and the visual appearance of the products was not affected by storage.

The moisture content and water activity of the products were barely affected by storage (Table 5, Table 7) and there was no microbial growth during storage (Table 7) because the water activity was too low for growth [2,37].

4. Conclusions

In conclusion, a tasty, low glycemic index (GI) gummy jelly product rich in natural antioxidants from nipa palm vinegar and nipa palm syrup, was developed. The product offered new opportunities for making commercial use of sustainably produced ingredients from nipa palm, a currently underutilized resource. For a potential consumer, the product offered a visually attractive flavorful snack combining a low GI, natural food antioxidants, and a long shelf-life. Low-GI gummy jellies rich in natural antioxidants are uncommon.

Funding

This research was funded by Walailak Business Incubation Center (WIC), Walailak University, Thailand, under project number WU-WIC-01/2564.

Institutional review board statement

This study was conducted according to the guidelines of the Declaration of Helsinki, and was approved by the Human Research Ethics Committee of Walailak University, Thailand. The approval numbers: WUEC-21-169-01 dated July 20, 2021, and WUEC-22-243-01 dated August 16, 2022.

Informed consent statement

All participants of this study provided informed consent to participate.

Data availability statement

All data relating to this study are included within this article. Data will be made available on reasonable request.

CRediT authorship contribution statement

Wilawan Palachum: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Resources, Validation, Visualization, Project administration, Writing - original draft, Writing - review & editing. Wiyada Kwanhian Klangbud: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Resources, Supervision, Validation, Visualization, Funding acquisition, Writing - original draft, Writing - review & editing. Yusuf Chisti: Supervision, Validation, Visualization, Writing - review & editing.

Declaration of competing interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests: Wilawan Palachum reports financial support provided by Walailak Business Incubation Center (WIC), Walailak University, Thailand.

Footnotes

Supplementary data to this article can be found online at https://doi.org/10.1016/j.heliyon.2023.e21873.

Appendix A. Supplementary data

The following is the Supplementary data to this article.

References

- 1.Baker M.T., Lu P., Parrella J.A., Leggette H.R. Consumer acceptance toward functional foods: a scoping review. Int. J. Environ. Res. Publ. Health. 2022;19:1217. doi: 10.3390/ijerph19031217. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Gunes R., Palabiyik I., Konar N., Toker O.S. Soft confectionery products: quality parameters, interactions with processing and ingredients. Food Chem. 2022;385 doi: 10.1016/j.foodchem.2022.132735. [DOI] [PubMed] [Google Scholar]

- 3.Palachum W., Choorit W., Manurakchinakorn S., Chisti Y. Guava pulp fermentation and processing to a vitamin B12-enriched product. J. Food Process. Preserv. 2020;44 doi: 10.1111/jfpp.14566. [DOI] [Google Scholar]

- 4.Gan D., Xu M., Chen L., Cui S., Deng C., Qiao Q., Guan R., Zhong F. Intake of sugar substitute gummy candies benefits the glycemic response in healthy adults: a prospective crossover clinical trial. Gels. 2022;8:642. doi: 10.3390/gels8100642. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Kia E.M., Ghaderzadeh S., Langroodi A.M., Ghasempour Z., Ehsani A. Red beet extract usage in gelatin/gellan based gummy candy formulation introducing Salix aegyptiaca distillate as a flavouring agent. J. Food Sci. Technol. 2020;57:3355–3362. doi: 10.1007/s13197-020-04368-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Teixeira-Lemos E., Almeida A.R., Vouga B., Morais C., Correia I., Pereira P., Guiné R.P.F. Development and characterization of healthy gummy jellies containing natural fruits. Open Agriculture. 2021;6:466–478. doi: 10.1515/opag-2021-0029. [DOI] [Google Scholar]

- 7.Palachum W., Klangbud W.K., Chisti Y. Spray-dried nipa palm vinegar powder: production and evaluation of physicochemical, nutritional, sensory, and storage aspects. Fermentation. 2022;8:272. doi: 10.3390/fermentation8060272. [DOI] [Google Scholar]

- 8.Laklaeng S.-n., Kwanhian W. Immunomodulation effect of Nypa fruticans palm vinegar. Walailak J. Sci. Technol. 2020;17:1200–1210. doi: 10.48048/wjst.2020.10719. [DOI] [Google Scholar]

- 9.Chatatikun M., Kwanhian W. Phenolic profile of nipa palm vinegar and evaluation of its antilipidemic activities, Evid. Based Complement. Alternat. Med. 2020;2020 doi: 10.1155/2020/6769726. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Senghoi W., Klangbud W.K. Antioxidants, inhibits the growth of foodborne pathogens and reduces nitric oxide activity in LPS-stimulated RAW 264.7 cells of nipa palm vinegar. PeerJ. 2021;9 doi: 10.7717/peerj.12151. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Phetrit R., Chaijan M., Sorapukdee S., Panpipat W. Characterization of nipa palm's (Nypa fruticans Wurmb.) sap and syrup as functional food ingredients. Sugar Tech. 2020;22:191–201. doi: 10.1007/s12355-019-00756-3. [DOI] [Google Scholar]

- 12.Saengkrajang W., Chaijan M., Panpipat W. Physicochemical properties and nutritional compositions of nipa palm (Nypa fruticans Wurmb) syrup. NFS Journal. 2021;23(2021):58–65. doi: 10.1016/j.nfs.2021.04.004. [DOI] [Google Scholar]

- 13.Saputro A.D., Van de Walle D., Dewettinck K. Palm sap sugar: a review. Sugar Tech. 2019;21:862–867. doi: 10.1007/s12355-019-00743-8. [DOI] [Google Scholar]

- 14.Trinidad T.P., Mallillin A.C., Sagum R.S., Encabo R.R. Glycemic index of commonly consumed carbohydrate foods in the Philippines. J. Funct.Foods. 2010;2:271–274. doi: 10.1016/j.jff.2010.10.002. [DOI] [Google Scholar]

- 15.Cheablam O., Chanklap B. Sustainable nipa palm (Nypa fruticans Wurmb.) product utilization in Thailand. Scientifica. 2020;2020 doi: 10.1155/2020/3856203. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Herrero M., Hugas M., Lele U., Wirakartakusumah A., Torero M. In: Science and Innovations for Food Systems Transformation. von Braun J., Afsana K., Fresco L.O., Hassan M.H.A., editors. Springer International Publishing; 2023. A shift to healthy and sustainable consumption patterns; pp. 59–85. [DOI] [Google Scholar]

- 17.Thomas D., Elliott E.J. Low glycaemic index, or low glycaemic load, diets for diabetes mellitus. Cochrane Database Syst. Rev. 2009;Cd006296 doi: 10.1002/14651858.CD006296.pub2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Breymeyer K.L., Lampe J.W., McGregor B.A., Neuhouser M.L. Subjective mood and energy levels of healthy weight and overweight/obese healthy adults on high-and low-glycemic load experimental diets. Appetite. 2016;107:253–259. doi: 10.1016/j.appet.2016.08.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Lobo V., Patil A., Phatak A., Chandra N. Free radicals, antioxidants and functional foods: impact on human health. Pharmacogn. Rev. 2010;4:118–126. doi: 10.4103/0973-7847.70902. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Cedeño-Pinos C., Martínez-Tomé M., Jordán M.J., Bañón S. Revalorisation of sage (Salvia lavandulifolia Vahl) by-product extracts as a source of polyphenol antioxidants for novel jelly candies. Antioxidants. 2023;12:159. doi: 10.3390/antiox12010159. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Rivero R., Archaina D., Sosa N., Leiva G., Coronel B.B., Schebor C. Development of healthy gummy jellies containing honey and propolis. J. Sci. Food Agric. 2020;100:1030–1037. doi: 10.1002/jsfa.10107. [DOI] [PubMed] [Google Scholar]

- 22.Lourenço S.C., Moldão-Martins M., Alves V.D. Antioxidants of natural plant origins: from sources to food industry applications. Molecules. 2019;24:4132. doi: 10.3390/molecules24224132. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.FDA . US Food and Drug Administration; Silver Spring, MD, USA: 2001. Bacteriological Analytical Manual: Chapter 3: Aerobic Plate Count.https://www.fda.gov/food/laboratory-methods-food/bam-chapter-3-aerobic-plate-count [Google Scholar]

- 24.Tan S.L., Sulaiman R., Rukayadi Y., Ramli N.S. Physical, chemical, microbiological properties and shelf life kinetic of spray-dried cantaloupe juice powder during storage. LWT. 2021;140 doi: 10.1016/j.lwt.2020.110597. [DOI] [Google Scholar]

- 25.Cedeño-Pinos C., Marcucci M.C., Bañón S. Contribution of green propolis to the antioxidant, physical, and sensory properties of fruity jelly candies made with sugars or fructans. Foods. 2021;10:2586. doi: 10.3390/foods10112586. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Aoac . twenty-first ed. AOAC International; Rockville, MD: 2019. Official Methods of Analysis of AOAC International. [Google Scholar]

- 27.Renaldi G., Junsara K., Jannu T., Sirinupong N., Samakradhamrongthai R.S. Physicochemical, textural, and sensory qualities of pectin/gelatin gummy jelly incorporated with Garcinia atroviridis and its consumer acceptability. Int. J. Gastron. Food Sci. 2022;28 doi: 10.1016/j.ijgfs.2022.100505. [DOI] [Google Scholar]

- 28.Sullivan D.M., Carpenter D.E. AOAC International; Rockville, MD, USA: 1993. Methods of Analysis for Nutrition Labeling. [Google Scholar]

- 29.Chen Z., Chen B., Yao S. High-performance liquid chromatography/electrospray ionization-mass spectrometry for simultaneous determination of taurine and 10 water-soluble vitamins in multivitamin tablets. Anal. Chim. Acta. 2006;569:169–175. doi: 10.1016/j.aca.2006.03.099. [DOI] [Google Scholar]

- 30.Phimolsiripol Y., Siripatrawan U., Teekachunhatean S., Wangtueai S., Seesuriyachan P., Surawang S., Laokuldilok T., Regenstein J.M., Henry C.J. Technological properties, in vitro starch digestibility and in vivo glycaemic index of bread containing crude malva nut gum. Int. J. Food Sci. Technol. 2017;52:1035–1041. doi: 10.1111/ijfs.13369. [DOI] [Google Scholar]

- 31.Delgado P., Bañón S. Determining the minimum drying time of gummy confections based on their mechanical properties. CYTA J. Food. 2015;13:329–335. doi: 10.1080/19476337.2014.974676. [DOI] [Google Scholar]

- 32.Preciado-Rangel P., Gaucín-Delgado J.M., Salas-Pérez L., Chavez E.S., Mendoza-Vllarreal R., Ortiz J.C.R. The effect of citric acid on the phenolic compounds, flavonoids and antioxidant capacity of wheat sprouts. Revista de la Facultad de Ciencias Agrarias UNCuyo. 2018;50:119–127. [Google Scholar]

- 33.Cano-Lamadrid M., Calín-Sánchez Á., Clemente-Villalba J., Hernández F., Carbonell-Barrachina Á.A., Sendra E., Wojdyło A. Quality parameters and consumer acceptance of jelly candies based on pomegranate juice “mollar de elche”. Foods. 2020;9:516. doi: 10.3390/foods9040516. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Hani N.M., Romli S.R., Ahmad M. Influences of red pitaya fruit puree and gelling agents on the physico-mechanical properties and quality changes of gummy confections. Int. J. Food Sci. Technol. 2015;50:331–339. doi: 10.1111/ijfs.12638. [DOI] [Google Scholar]

- 35.Dai F., Chen W.F., Zhou B. Antioxidant synergism of green tea polyphenols with alpha-tocopherol and L-ascorbic acid in SDS micelles. Biochimie. 2008;90:1499. doi: 10.1016/j.biochi.2008.05.007. –1505. [DOI] [PubMed] [Google Scholar]

- 36.Myint K.z., Zhou Z., Xia Y., Fang Y., Wu M., Zhu S., Shen J. Stevia polyphenols: a stable antioxidant that presents a synergistic effect with vitamin C. J. Food Process. Preserv. 2021;45 doi: 10.1111/jfpp.15317. [DOI] [Google Scholar]

- 37.Ergun R., Lietha R., Hartel R.W. Moisture and shelf life in sugar confections. Crit. Rev. Food Sci. Nutr. 2010;50:162–192. doi: 10.1080/10408390802248833. [DOI] [PubMed] [Google Scholar]

- 38.Hartel R.W., von Elbe J.H., Hofberger R. Springer; Cham: 2018. Confectionery Science and Technology. [DOI] [Google Scholar]

- 39.Tireki S., Sumnu G., Sahin S. Correlation between physical and sensorial properties of gummy confections with different formulations during storage. J. Food Sci. Technol. 2021;58:3397–3408. doi: 10.1007/s13197-020-04923-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Kayanna N., Suppavorasatit I., Bankeeree W., Lotrakul P., Punnapayak H., Prasongsuk S. Production of prebiotic aubasidan-like β-glucan from Aureobasidium thailandense NRRL 58543 and its potential as a functional food additive in gummy jelly. LWT. 2022;163 doi: 10.1016/j.lwt.2022.113617. [DOI] [Google Scholar]

- 41.Burey P., Bhandari B.R., Rutgers R.P.G., Halley P.J., Torley P.J. Confectionery gels: a review on formulation, rheological and structural aspects. Int. J. Food Prop. 2009;12:176–210. doi: 10.1080/10942910802223404. [DOI] [Google Scholar]

- 42.Hartel R.W., Shastry A.V. Sugar crystallization in food products. Crit. Rev. Food Sci. Nutr. 1991;30:49–112. doi: 10.1080/10408399109527541. [DOI] [PubMed] [Google Scholar]

- 43.Jenkins D.J., Wolever T.M., Taylor R.H., Barker H., Fielden H., Baldwin J.M., Bowling A.C., Newman H.C., Jenkins A.L., Goff D.V. Glycemic index of foods: a physiological basis for carbohydrate exchange. Am. J. Clin. Nutr. 1981;34:362–366. doi: 10.1093/ajcn/34.3.362. [DOI] [PubMed] [Google Scholar]

- 44.Sievenpiper J.L., Chan C.B., Dworatzek P.D., Freeze C., Williams S.L. Nutrition therapy. Can. J. Diabetes. 2018;42:S64–S79. doi: 10.1016/j.jcjd.2017.10.009. [DOI] [PubMed] [Google Scholar]

- 45.Brand-Miller J., Foster-Powell K. Da Capo Lifelong Books; Boston, MA: 2006. The New Glucose Revolution: the Authoritative Guide to the Glycemic Index-the Dietary Solution for Lifelong Health. [Google Scholar]

- 46.Ojo O., Ojo O.O., Adebowale F., Wang X.H. The effect of dietary glycaemic index on glycaemia in patients with Type 2 diabetes: a systematic review and meta-analysis of randomized controlled trials. Nutrients. 2018;10:373. doi: 10.3390/nu10030373. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.USDA . FDC published; 2021. Gummies (Branded, 1653916); United States Department of Agriculture.https://fdc.nal.usda.gov/fdc-app.html?fbclid=IwAR175EslYbkHEgrdJs9eZfGHYDneouISGszXEzCfGPx_WI9gFkDmDEp7Rc#/food-details/1653916/nutrients Available online: [Google Scholar]

- 48.USDA . United States Department of Agriculture: FDC published; 2021. Apple, Strawberry and Raspberry Puree Flavored Soft Gummies, Apple, Strawberry and Raspberry (Branded, 1991948)https://fdc.nal.usda.gov/fdc-app.html?fbclid=IwAR2Cxm2rXU49jtptu3OkcBuB9KGUbjt_6cQbnnQpv2NQW_TfGS_qMxeg0Vo#/food-details/1991948/nutrients Available online: [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

All data relating to this study are included within this article. Data will be made available on reasonable request.