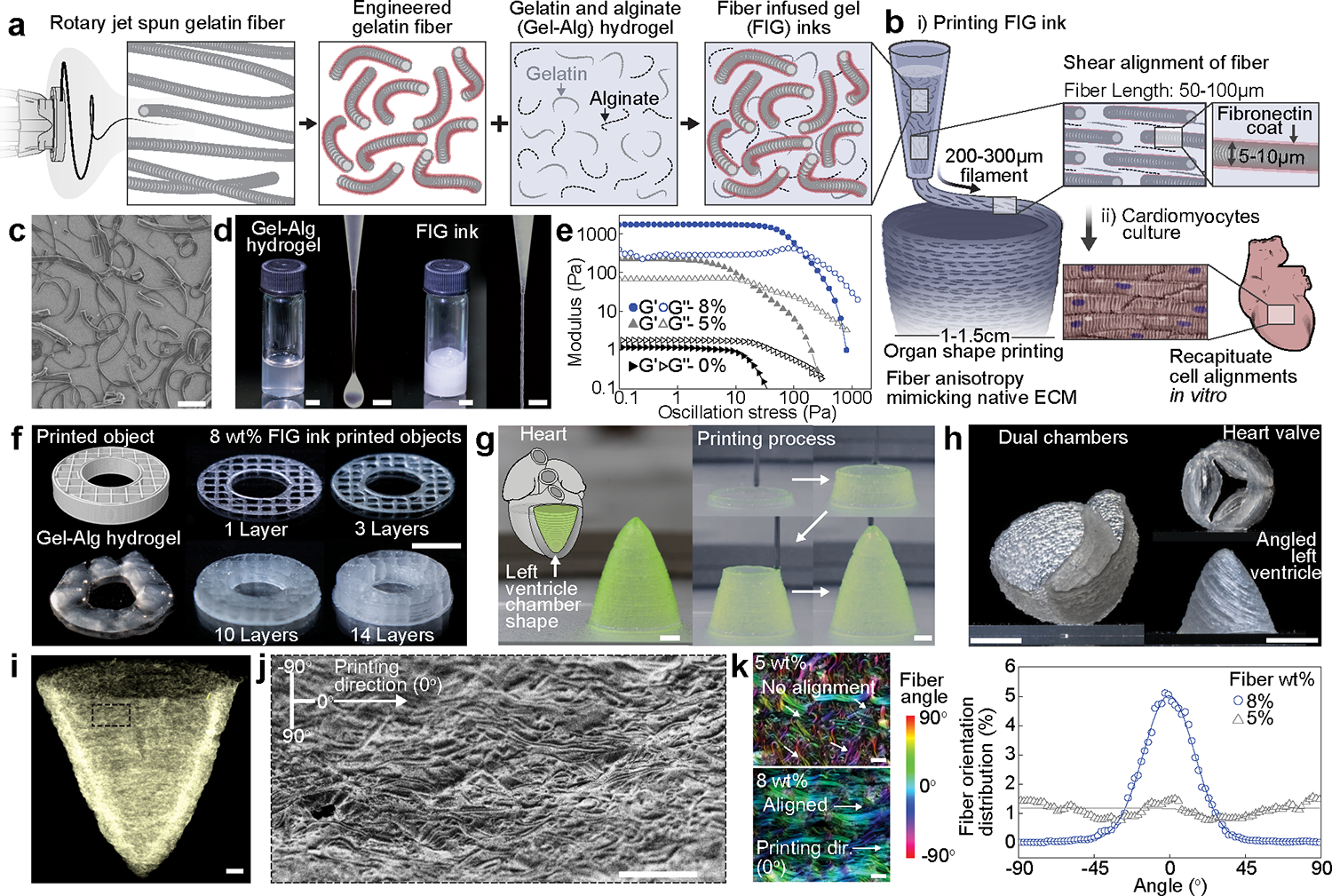

Fig. 1. Development of gelatin fiber infused gel (FIG) inks for free-standing 3D printed tissue scaffolds with cellular alignment cues.

a-b, Schematic illustration of FIG ink components. As fragmented gelatin fibers are combined with Gel-Alg hydrogels (Red, Fibronectin (FN)) (a), the ink viscosity increases and displays a solid-like behavior, which allows for 3D printing of ventricle scaffolds with hierarchical structure (b). Fiber alignment occurred under shear stress (τ) during 3D printing leads to native ECM anisotropic structural features in 3D scaffolds, promoting tissue alignment and organization to recapitulate in vivo heart muscle (b). c, A scanning electron microscopy image showing truncated gelatin fibers. Scale bar, 100 μm. d, Comparison of Gel-Alg ink (0 wt% fiber, left panel) or FIG ink (8 wt% fiber, right panel). The Gel-Alg hydrogel has low viscosity liquid-like behavior (left). FIG inks behave solid-like at rest and extrude in a continuous stream (right). Scale bar, 2mm. e, Oscillation stress sweep test to measure storage (Gʹ) and loss (Gʺ) modulus, showing concentration- and strain-dependent shear thinning behavior and sol-gel transition f, 3D donut shape with rectilinear infill pattern with increasing number of stacking layers, showing high shape retention of using FIG inks. g, A cone-shaped model of the self-supporting inverted left ventricle printed in circumferential direction. Scale bars, 2 mm. h, Self-supportive dual ventricle chambers and a heart valve printed in circumferential direction and an angled left ventricle printed in diagonal (30°) titled direction. Scale bars, 5 mm. i, A micro-computed tomography image of the 3D printed ventricle scaffold after critical point drying, showing fiber structure in the 3D printed geometry. Scale bars, 1 mm. j, A scanning electron microscopy image of the 3D printed ventricle scaffold showing fiber alignments in printing direction. Scale bar, 200 μm. k, Analysis of fiber alignment from confocal images of the 3D printed ventricle FIG scaffolds with 5 and 8 wt% fibers and corresponding fiber orientation angular distribution graph. 0° indicates printing direction. Scale bars, 100 μm.