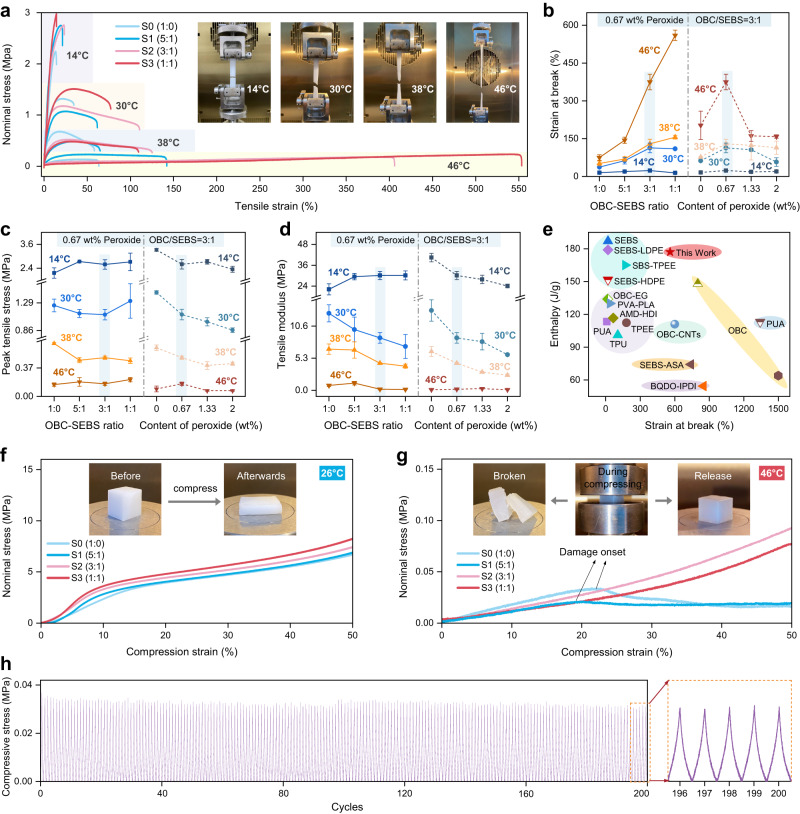

Fig. 5. Mechanical Properties of PW@OBC-SEBS composites (F-FSPCMs).

a Tensile stress-strain curves of F-FSPCMs at different temperatures. b Influence of OBC-SEBS ratio and peroxide concentration on strain at break. c Effect of OBC-SEBS ratio and peroxide concentration on tensile peak stress. d Impact of OBC-SEBS ratio and peroxide concentration on tensile modulus. e Comparison of strain at break and enthalpy of our prepared F-FSPCMs with literature24–26,40,42–53. And the detailed information is shown in Table S3 (Supplementary). f Compression stress-strain curves of F-FSPCMs below the melting point. g Compression stress-strain curves of F-FSPCMs above the melting point. h Cyclic compression performance of F-FSPCMs (S2-0.67) at 46 °C compressed to 30% strain over 200 cycles. Error bars in b–d are standard deviation (s.d.) from 3 samples.