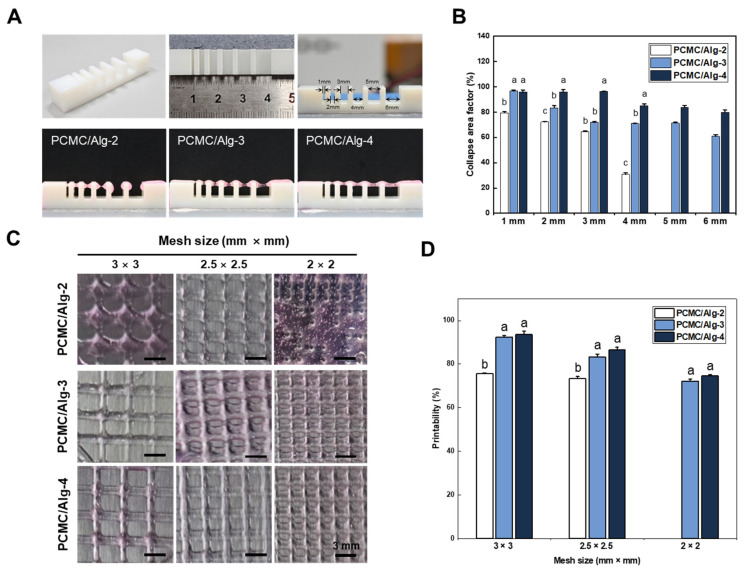

Figure 4.

Three-dimensional printability test. (A) Filament collapse tests were conducted at various distances between the set pillars. PCMC was subjected to collapse tests using various concentrations of alginate, and the results were analyzed. (B) The quantified results of the filament collapse test. The collapse area coefficient decreased with increasing column distance for all compositions. PCMC/Alg-2 did not exhibit overhang capability at distances of 5 mm and 6 mm. In contrast to PCMC/Alg-2, both PCMC/Alg-3 and PCMC/Alg-4 exhibited filament stability without notable collapse. Error bars indicate the standard mean of errors. The same letter means statistical insignificance (Duncan’s new multiple range test, p ≤ 0.05). (C) Optical images of PCMC/Alg bioink depending on various mesh sizes. Evaluated the capability to print mesh of various sizes on each scaffold. PCMC/Alg-2 failed to print a 2 × 2 mesh size and collapsed, but it could represent larger meshes. PCMC/Alg-3 and PCMC/Alg-4 demonstrated the capability to print mesh structures of all sizes. (D) Quantification of 3D printability. Printing ability was calculated as a percentage by dividing the actual mesh size by the intended mesh size. Printability decreased as the mesh size was reduced in all groups. Error bars indicate the standard mean of errors. The same letter means statistical insignificance (Duncan’s new multiple range test, p ≤ 0.05).