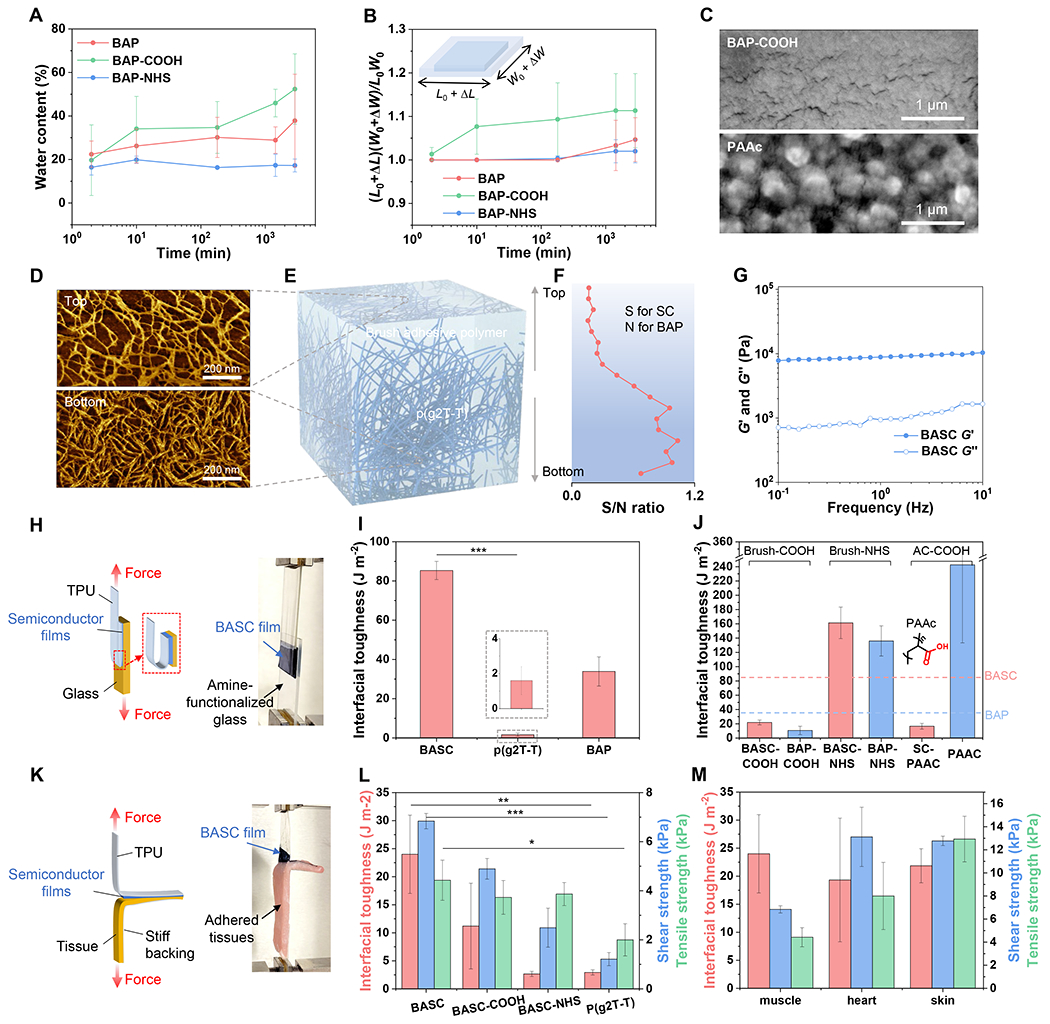

Fig. 2. Adhesive-relevant properties of the BASC films.

(A to B) Water content measured through gravimetric analysis (A) and dimensional swelling (B) of the BAPs with three types of side-chain designs when soaked in PBS solution over time. (C) SEM images showing the microscale features of a BAP-COOH film and a PAAc film in the dry state. (D) AFM phase images showing the top and bottom surfaces of a BASC film. (E) 3D schematic morphology of a BASC film. (F) XPS-measured ratios between the S element and the N element from the top to the bottom surface of a BASC film. (G) Rheological measurement of the BASC polymer in the dry state. (H) 180-degree peel test (ASTM D3330) for interfacial toughness measurement on rigid substrates. (I) Interfacial toughness of the adhesion between a BASC film and an amine-functionalized, dry glass substrate, in comparison to a neat p(g2T-T) film, and a BAP film. (J) On amine-functionalized glass substrates, interfacial toughness achieved by BASC films and BAP (including PAAc) films with different types of side chains. The two dashed lines mark the levels of interfacial toughness for the BASC and BAP films from (I). (K) 180-degree peel test (ASTM F2256) for interfacial toughness measurement on bio-tissues. (L) Interfacial toughness, shear strength, and tensile strength of the adhesion between wet porcine muscle tissues and a BASC film, a BASC-COOH film, a BASC-NHS film, and a neat p(g2T-T) film, respectively. (M) Interfacial toughness, shear strength, and tensile strength achieved by BASC films on various wet tissue surfaces. Values in I-J, L-M represent the mean and the standard deviation (n = 3). Statistical significance and P values are determined by two-sided Student’s t-test: *P<0.05; **P<0.01.