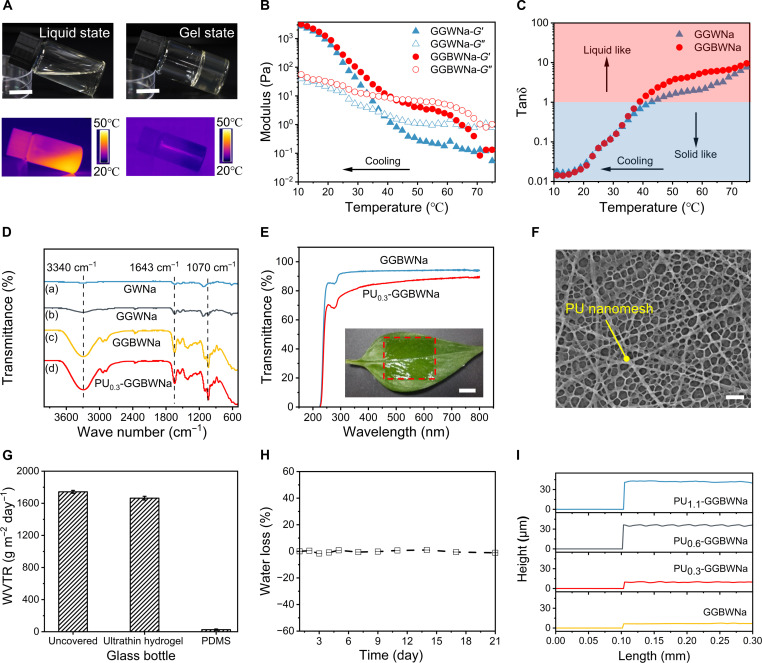

Fig. 2. Characterization of thermally responsive phase change hydrogel materials and the ultrathin hydrogels.

(A) Photographs and infrared camera images of hydrogels at high temperature (55°C) and room temperature (25°C), illustrating their temperature-dependent phase change properties. Scale bar, 1 cm. (B) Rheological characterization of hydrogels solution with different recipes at a temperature sweep from 75° to 10°C, showing their transition between viscous liquid state and viscoelastic gel state. (C) The corresponding tanδ (G″/G′) calculated from (B). (D) FTIR spectra of hydrogels with different formulations and the ultrathin hydrogel. (E) Optical transmittance of the GGBWNa and PU0.3-GGBWNa, the insert photograph demonstrating the ultrathin hydrogel conformably attached on a green leave. Scale bar, 1 cm. (F) SEM image of the internal structure of the freezing-dried ultrathin hydrogel. Scale bar, 5 μm. (G) Comparison of WVTR for an uncovered bottle, a bottle covered with 1000-μm-thick PDMS film, and a bottle covered with ~10-μm-thick ultrathin hydrogel, respectively. (H) Anti-drying performance of the ultrathin hydrogel for 21 days under ambient environment. (I) Thickness comparison of hydrogels and PU nanomesh–reinforced hydrogels. Error bars represent the SD of the measured values (n = 3).