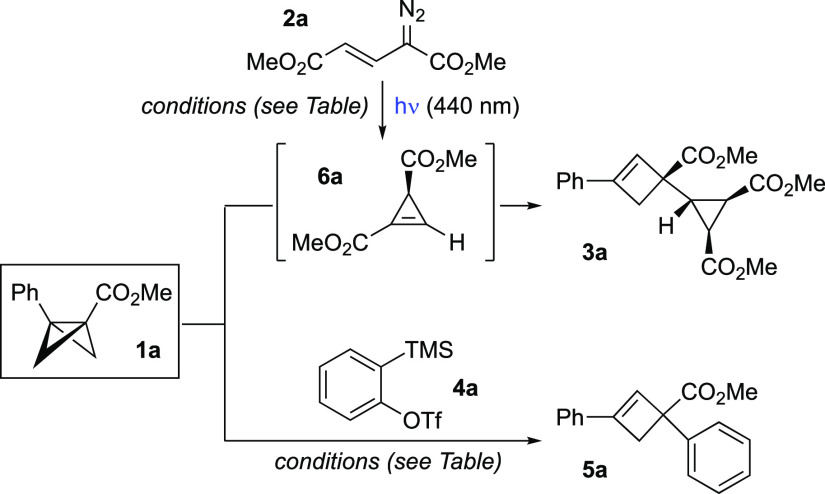

Table 1. Optimization of Ene Reactionsa.

| entry | substrate | conditions | time (h) | 2a/4a (equiv) | yield 3a/5a (%) |

|---|---|---|---|---|---|

| 1 | 2a | MeCN | 4 | 1 | 67 |

| 2 | 2a | MeCN | 4 | 2 | 88 |

| 3 | 2a | MeCNb | 8 | 2 | 21 |

| 4 | 2a | MeCNc | 4 | 2 | n.r. |

| 5 | 2a | toluene | 4 | 2 | 20 |

| 6 | 2a | Et2O | 4 | 2 | 38 |

| 7 | 2a | CH2Cl2 | 4 | 2 | 38 |

| 8 | 2a | THF | 3 | 2 | 31 |

| 9 | 2a | MeOH | 3 | 2 | 44 |

| 10 | 4a | KF, THFd | 12 | 1.2 | 85 |

| 11 | 4a | CsF, MeCN | 12 | 1.2 | 82 |

| 12 | 4a | KF, THFd | 12 | 1.5 | 96 |

| 13 | 4a | KF, THFd | 4 | 1.5 | 98 |

| 14e | 4a | KF, THFd | 4 | 1.5 | 98 |

Reactions were carried out using 0.1 mmol of 1a (for reaction with 2a) or 0.2 mmol scale of 1a (for reaction with 4a). Isolated yields are reported.

Reaction conducted at 0 °C.

Reaction carried out in the dark.

Reaction conducted with 1 equiv 18-C-6 per equiv. KF.

Performed on 1.0 mmol scale. n.r. = no reaction.