Highlights

-

•

Analysis showed that 85% of published studies involve laboratory tests revealing a gap with theoretical and field studies.

-

•

Cavitation and thermal effects caused by acoustic fields are the most accepted mechanisms influencing US stimulation.

-

•

The application of US waves has shown boosts of >90% in oil recovery rates, and a decrease of >80% in viscosity values.

-

•

Combination of US with another EOR method improves efficiency beyond that obtained using only the standalone techniques.

Keywords: Ultrasound, Sonochemistry, Ultrasonic Stimulation, Well Enhancement, EOR

Abstract

In the last two decades, ultrasound (US) technologies research has increasingly earned attention for applications in the oil and gas industry. Numerous laboratory and field research have proven ultrasonics as an efficient, sustainable and cost-effective technology for improving well productivity. This paper pursues the elaboration of a comprehensive review of the most recent research related to ultrasonic technologies for applications in the oil and gas industry. Statistical analysis of different functional categories and classification of the research publications were performed. Considering the research reviewed, there is a huge gap between numerical and field studies in comparison with the numerous laboratory studies, deeming it necessary to increase efforts on developing mathematical and numerical models and field-testing cases of the ultrasonic effect. A comprehensive review of the ultrasonic waves’ mechanisms of action for enhanced oil recovery (EOR) and emulsification/demulsification was conducted. Despite the lack of consensus regarding the mechanisms, cavitation and thermal effects on wellbore fluid and formation rock have been widely accepted as two of the most influencing mechanisms. A compilation of the state-of-the-art research of numerical, laboratory and field studies in the last two decades was assembled. Most authors agreed that ultrasonics is a highly efficient method for EOR and emulsion treatment if the optimal conditions are identified and achieved. The development of screening criteria for the application of ultrasonic waves was recommended, as this technique and the same parameters should not be utilized for all reservoir types. Treatment with ultrasound waves has shown improvement of oil recovery efficiency rates of over 90% and viscosity reduction values over 80%. The most efficient results were observed when in combination with another conventional EOR method, where ultrasound boosts recovery efficiency. Potential new applications related to rock mechanics and additional research topics were also recommended.

1. Introduction

Current oil well stimulation methods such as acid stimulation are in many cases ineffective and might cause additional operational issues such as emulsion formation, secondary chemical reactions, among others. These methods also involve the use of dangerous contaminants jeopardizing the facilities, personnel, and the environment. Emerging new technologies such as ultrasound stimulation present numerous advantages compared to conventional methods required by the Oil & Gas (O&G) industry to perform maintenance operations and oil well stimulations. The present work intends to perform a comprehensive review of the available literature gathered regarding existing laboratory studies and field tests of the ultrasound technology.

Previous studies from different authors covered state of the art summaries for research related to ultrasound with quite specific scopes and timelines. The current work intends continuing previous researchers’ efforts with a wider focus integrating these reviews and publications, analyzing the most prominent applications for ultrasound technologies, and updating global summary with the latest publications and trends in ultrasonics and sonochemistry research.

After extensive research of different databases was carried out and organized into an indexed matrix related to ultrasonic/ultrasound technologies and sonochemistry. The resulting matrix was classified and examined considering industries or areas of study related to engineering, manufacturing and services. More than 470 research publications (over 7,000 pages of technical papers), 41 patents and 25 technical books related to ultrasound stimulation were accounted for in a period of two decades approximately.

Finally, the goal is to identify and unify criteria where there are sufficient arguments in terms of the research of acoustic cavitation mechanisms of action, key applications within the O&G industry, current updates in terms of equipment and technologies available for field applications, comprehensive analysis of advantages and disadvantages, and final recommendations for further research necessary to boost efficiency and optimize operational parameters.

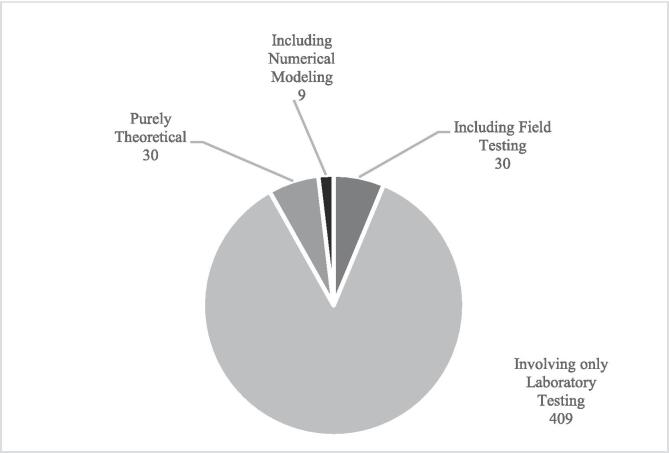

For statistical analysis, research publications were classified per type of study, among other categories. These indicators covered the nature of the study such as purely theoretical studies, mathematical or computational modeling, and studies involving any laboratory testing and/or field testing, and in some cases, a combination of those. The analysis of these indicators helped assess the current state-of-the-art and the progress in mature technologies ready-to-use in the industry.

The distribution of publications per type of study can be seen in Fig. 1. In concordance with numerous authors, a lack of sufficient mathematical and numerical models simulating the mechanisms of US phenomena in the near wellbore area, and a dire necessity of field-testing applications in comparison with the laboratory studies can be observed. Most of the research only comprises laboratory experiments and measurements for specific applications or specific conditions. Further research simulating near wellbore conditions such as higher temperature and pressure or field tests to validate numerous experimental results are in order. The considerable absence of field tests publications might also be due to the fact that additional field experiences exist, but they have not been documented or published.

Fig. 1.

Distribution of publications related to ultrasound technologies per type of study.

2. US in enhanced oil recovery

The main application found for US-assisted technologies aims for increasing oil production as an EOR method after the primary and secondary methods can no longer provide improved oil yield. Development and optimization of research resources and efficiency increase has been a priority. For this reason, the first task is to identify and understand the mechanisms that affect the ultrasonic waves to improve oil yield in the reservoir. It was noticed that the accepted mechanisms of action differ from one study to another, nonetheless, there are mechanisms widely accepted which can be considered useful for further research and applications.

One of the most detailed studies about the mechanisms of action of ultrasound and the main variables influencing oil recovery found was done by Agi et al. [12]. It is considered that ultrasound can improve the movement of oil in the reservoir, by altering the capillary forces through changes in the adhesion between rock and fluid and accelerate the gravitational forces allowing the segregation of fluids with multiple phases. Ultrasound mechanisms capable of influencing these forces were identified as cavitation, coalescence, Bjerknes force, microjets, peristalsis movement, sonocapillary effect, and acoustic streaming.

Other classifications of these mechanisms for EOR methods contemplate crude oil viscosity reduction, wax crystallization inhibition and oil reservoir permeability enhancement (formation damage) as the responsible for the oil mobility increase (Luo et al. [56]), or mechanical vibration, cavitation, and thermal action (Wang et a. [97]). A brief description of the latter is shown in Table 1.

Table 1.

Mechanisms for EOR proposed by Wang et al. [97].

| Mechanism | Description |

|---|---|

| Mechanical vibrations |

|

| Cavitation |

|

| Thermal action |

|

Despite the discrepancies between the revised studies, the most widely recognized mechanism in ultrasonic wave treatment is cavitation, and for that reason, understanding the parameters affecting cavitation has been of utmost importance for the optimization of ultrasound and its applications. For the optimization of cavitation, a wider consensus of the influencing ultrasound parameters affecting this phenomenon was found in the literature.

The main parameters affecting cavitation are classified between two categories: acoustic parameters and medium properties (Luo et al. [56]). The acoustic parameters identified include frequency, acoustic intensity, exposure or treatment duration, distance from the US source, operation mode and field type. The medium properties consist of fluid viscosity, interfacial tension, saturated vapor pressure, dissolved gas, and solid porosity.

Despite the previous research publications, questions still surround the use and optimization of US-assisted oil technologies. The complex physical and chemical mechanisms involved, and the lesser understanding and incomplete mathematical models of these phenomena cripple the possibility of effectively simulating the behavior and efficiency of ultrasound waves. The lack of detailed numerical models has been widely recognized and solving this deficit is necessary to optimize parameters, preserve resources and save research time.

EOR mechanisms such as vibration, bubble cavitation, and friction produced by ultrasound can prevent coagulation of heavy oils and reduce oil viscosity by up to 86 %. Additionally, ultrasound waves can lead to pore deformation, increasing oil recovery and restoring damaged formations, and ultimately, heat generated during ultrasonic irradiation also reduces the viscosity and aids emulsion rupture (Otumudia et al. [74]). Combined with solvent treatment consisting of toluene and n-heptane, ultrasound can alter the asphaltene aggregation and chemical structure in heavy oils, and further decrease the viscosity in comparison to samples treated with only one of the techniques (Qajar et al. [78]).

US treatment efficiency is higher with lower frequencies between 20 and 30 kHz, acoustic intensities lower than critical values, increased irradiation time, intermittent US field application and lower fluid viscosity (Adeyemi et al. [6]). He studied and reviewed US-assisted technologies for the O&G industry, focused on emulsification and demulsification and EOR, as well as studies of the optimization of fluid and US properties in EOR. He also introduced the idea of additional research studies of new treatment conditions such as the use of Raschig rings, temperature, and salinity of the environment, and how they affect the US effect.

There have been numerous research publications studying the comparison and combination of US and other stimulation technologies such as chemical injection. One of these studies was carried out by Hamidi et al. [32], Mo et al. [58], Khan et al. [46], among others. Ultrasound showed promise in improving core permeability considering the overall of efficiency, cost, and safety in comparison with other methods. Moreover, the development of ultrasound technology could be aimed at working in synergy with other EOR methods, complementing each other to further improve recovery rates and decrease operational costs. For example, during chemical treatment, a combination of the chemical injection and ultrasound enables the chemical to penetrate deep into the formation and even into the smallest low permeability pores to remove pore bridges, allowing an increase in the efficiency, a reduction in the volume of required chemicals and saving operation time.

Ultrasound was recognized as an inexpensive and ecological method that can be applied in any type of reservoir, protects the well against damage, prevents heat loss, and enables stimulation freely Shafiai et al. [86], leading to an increasing implementation of ultrasonic technologies for oil recovery in the past years.

A global summary of experimental EOR applications, mechanisms and other US-related research studies was performed. Numerous applications as alternative EOR methods for US-assisted formation damage reduction, viscosity reduction, surfactant flooding, CO2 flooding, waterflooding, enhanced diffusion of colloids, among others (see Table 2.). This summary might support the identification of research gaps, development of screening criteria, parameter optimization, and evaluation of technologies for field applications.

Table 2.

Research publications with experimental testing.

| Application | Reference | Study Overview |

|---|---|---|

| CO2 flooding | Wang et al. [95] | US application for oil–gas miscibility during CO2 flooding and extraction of tight oils |

| Hamidi et al. [36] | US-assisted CO2 flooding in a porous media, parameters optimization incl. temperature | |

| Enhanced diffusion of colloids | Yeh and Juarez [102] | US application for colloidal particles mobility increase of in porous media |

| EOR |

Qajar et al. [78] | Effect of US and solvent treatment on heavy oil rheology and asphaltene structure |

| Abdulfatah [1] | US as EOR using Niger Delta crude oil | |

| Agi et al. [10] | Acoustic parameters study for recovery of kerosene and paraffin | |

| Arabzadeh and Amani [20] | US as EOR by means of free fall gravity drainage | |

| Mohsin and Meribout [62] | Model for US as EOR | |

| Naderi and Babadagli [70] | Immiscible displacement processes under US waves | |

| Najafi [71] | US as EOR by means of free gravity drainage | |

| EOR from sludges | Lins et al. [53] | Study of US treatment combined with mechanical stirring for oil recovery from waste lubricant oil |

| Luo et al. [55] | Effect of US treatment on oil recovery from oily sludges | |

| He et al. [37] | US parameters study on EOR from sludges | |

| Gao et al. [27] | US waves on the oil components removal from oily sludge | |

| Formation damage |

Otumudia et al. [75] | Effect of ultrasound in removing plugging using glass models to simulate oil reservoirs |

| Ghamartale et al. [29] | Permeability and pore structure enhancement using US | |

| Wang and Huang [96] | Water-induced damage treatment using US and chemicals | |

| Khan et al. [44] | Permeability recovery on water-induced damaged cores using US | |

| Naderi and Babadagli [69] | Capillary interaction and EOR study using US waves on rocks | |

| Taherynia et al. [92] | Imbibition studies on limestone samples from Iranian fields | |

| Khan et al. [47] | Permeability recovery on damaged cores using chemicals and US | |

| Guo et al. [31] | Effect of US waves on fluid density, porosity and permeability | |

| Li et al. [49] | Effect of US on shale gas flow characteristics and gas production | |

| Mo et al. [58] | Colloidal precipitates removal using US and chemicals | |

| Karami et al. [42] | Condensate blockage removal using US treatment | |

| Ainuddin et al. [15] | Influence of US amplitudes on the removal of condensate in heterogeneous glass packs | |

| Khan et al. [45 ] | Removal of calcium carbonate in the near wellbore region | |

| Khan et al. [46] | Comparison of US and chemical to remove calcium carbonate plugs | |

| Pu et al. [77] | Removal of inorganic scale damage using US | |

| Zhang et al. [106] | Removal of calcium carbonate using US and chemical treatment | |

| Kunanz and Wolfel [48] | Scale removal using US treatment | |

| Xu and Bao [100] | Removal of asphaltene using US and chemicals | |

| Zhou and Wang [108] | Removal of paraffins using US and chemicals | |

| Otumudia et al. [73] | US parameters and rock pore geometry on asphaltene removal | |

| Rezaei Dehshibi et al. [82] | Study of effect of US treatment on asphaltene deposition | |

| Salehzadeh et al. [85] | Study of US effect of asphaltene aggregation and deposition | |

| Mousavi et al. [63] | US effect on rheological prop. and viscosity of heavy oils | |

| Wang et al. [99] | Effect of frequency on removing drilling fluid, paraffin deposition, polymer and inorganic scale plugs | |

| Surfactant flooding |

Agi et al. [14] | Paraffin recovery using US along with water and surfactant flooding enhancement and critical micelle concentration study |

| Hamidi et al. [34] | Effect of US on phase behavior of surfactant-brine-oil system | |

| Viscosity reduction | Tahmasebi Boldaji et al. [93] | US effect on heavy oil viscosity using mathematical and ANFIS models |

| Cui et al. [24] | Effect of metallic nickel particles addition in the US treatment process for increased cavitation | |

| Lv et al. [88] | Effect of US on the viscosity and pour point of crude | |

| Hua et al. [38] | Effect of US on the viscosity of heavy crude oil | |

| Rezaei Dehshibi et al. [81] | Study of the US assisted recovery of two crude oils with differences in viscosity (light and heavy oil) | |

| Shie et al. [87] | Application and mechanism of ultrasonic static mixer in heavy oil viscosity reduction | |

| Mullakaev et al. [68] | US effect on the viscosity and congelation temperature of crude oils with various compositions | |

| Hamidi et al. [35] | Effect of US on pressure drop and viscosity in porous media | |

| Razavifar and Qajar [80] | US effect on viscosity of oil with a high asphaltene concentration | |

| Aliev et al. [17] | US influence on rheological properties of heavy oil | |

| Rahimi et al. [79] | US effect on rheological behavior of extra heavy oil | |

| Wang et al. [98] | US effect on ultra-heavy oil viscosity reduction | |

| Waterflooding |

Alhomadhi et al. [16] | Effect of US on mobility of oil during waterflooding |

| Li et al. [50] | US-assisted waterflooding in low-permeability reservoirs | |

| Mohammadian et al. [60] | US-assisted waterflooding as oil recovery method | |

| Mohammadian et al. [61] | US-assisted waterflooding as oil recovery method | |

| Mohammadian et al. [59] | US effect on oil recovery in waterflooding | |

| Taheri Shakib et al. [90] | KCl scales removal using US-assisted waterflooding | |

| Taheri Shakib et al. [91] | NaCl scales removal using US-assisted waterflooding | |

| Nanotechnology | Agi et al. [13] | US assisted flooding and cavitation to enhance heavy oil recovery using empty fruit bunch SiO2 nanoparticles (EFBSNP) |

| Agi et al. [11] | US-assisted crystalline starch nanoparticles production w/ ascorbic acid |

Regarding advantages in the equipment for ultrasonic stimulation, two main equipment are used in the sonication process: ultrasound generators and transducers. Most used transducers in the field of acoustic oil recovery are made piezoelectric ceramic transducers (PZT). However, such piezoelectric ceramic transducers are prone to a large capacitive resistance in a transmission system and high temperature sensibility, thus, reducing the system efficiency and resulting in a great waste of energy, observing transmission efficiencies around 10 % to 20 % (Wang et al. [97]). A new design of transducers consisting of lithium niobate crystals could increase the temperature resistance threshold up to 1200 °C and make them able to withstand the harshest downhole environments with higher pressure and temperature conditions (Agi et al. [12]).

Research surrounding field testing has been scarce amongst the entire research publications. Most of the published work which includes field testing has been carried out in Russia by Abramov, Abramova, Mullakaev et al. (Table 3) and proved that ultrasonic stimulation can successfully increase oil production by reducing formation damage and increasing oil mobility (by means of US-assisted viscosity reduction, heat generation and capillary effect). More recently, Chang et al. [23] studied the successful application of a Swiss ultrasonic stimulation technology in offshore wells in Asia. High power ultrasonic stimulation was applied in two offshore wells and results showed an increase of oil production of 30 % in one of the wells and restored communication between the production tubing and casing by removing the wax clogging the gas lift valves in the other well. There has not been published any research related to field testing of ultrasound technologies for EOR since 2019.

Table 3.

Summary of research publications related to US field tests.

| Reference | Overview | Main Characteristics | Findings |

|---|---|---|---|

| Chang et al. [23] | First application of ultrasonic technology in offshore wells in Southeast Asia | Irradiation time 20 min/ft Frequency 20 kHz US power 1 kW |

|

| Abramov et al. [3] | Study of influence of ultrasound on fluid viscosity under reservoir conditions | US generator 9 kW Frequency 19 kHz Max. temperature 65 °C Exposure time 24 h |

|

| Mullakaev et al. [65], [66] | Testing of US equipment in 27 wells in Samotlorsk field | Frequency 19 kHz Max. temperature 85 °C US power 2 kW |

|

| Abramov et al. [2] | Study of a selective ultrasound technique for perforated regions in horizontal wells with high water cut | Oil density 940 kg/m3 Paraffin content 47 wt% Viscosity 6,800 mPa.s US generator 2–10 kW Frequency 13–26 kHz |

|

| Mullakaev et al. [64], [67] | Testing of thermo-acoustic equipment in Samotlorsk field, Samara region and Utah, USA | Frequency 19 kHz Max. temperature 85 °C US power 2 kW |

|

| Abramova et al. [5] | US treatment for enhanced oil recovery | Over 100 wells with different characteristics Frequency 13–26 kHz |

|

| Abramov et al. [4] | Application of ultrasonic enhancement on failing wells by stimulating the wells with an ultrasound source | Permeability 20 mD Porosity 15 % Frequency 18–27 kHz US power 10 kW |

|

There has been some debate about the criteria for evaluation of wells for ultrasound treatment. A reservoir, fluid and optimal wave properties analysis has been discussed and recommended in order to increase the success of the treatment, as well as pulse or continuous mode of operation before employing ultrasound stimulation. Agi et al. [12] proposed criteria for selection of suitable wells from light and heavy oil reservoirs depending on fluid and reservoir properties. Field tests showed good improvement in oil recovery and decrease in water cut shown under the influence of ultrasound at the specific conditionsHamidi et al. [32]consistent with the mentioned criteria.

Shafiai et al [86] considered the idea that one specific technique should not be utilized for all reservoir types, making it necessary to perform an EOR screening by analyzing the work of Kamari et al. [40] and Kang et al. [41]. The most suitable EOR methods need to be identified for specific reservoir conditions which can be obtained by selecting an optimized method among alternatives or prioritizing alternatives based on reservoir characteristics and oil properties criteria. Summaries compiled in this work might contribute to the development of screening criteria for US-assisted technologies successful application or combination with other EOR techniques such as emulsification, water/surfactant/CO2 flooding, hydrocarbon gas miscible, polymer processes, among others.

3. US in emulsion treatment

Important applications for the ultrasonic waves in the O&G were found to treat emulsions, for both emulsification and demulsification. Ultrasonic assisted methods and technologies showed the ability to improve oil recovery and emulsions separation. Same as for EOR applications, it was observed that combined treatments with ultrasound waves assisting other conventional methods have been studied, showing that US-assisted emulsion separation methods can be considerably more efficient than standalone treatments.

Table 4 shows a list of the most recent research for US alone and US-assisted technologies for emulsion treatment, showing a range of studies to understand the main influencing parameters and mechanisms, emulsification and demulsification applications, and oil recovery rates obtained.

Table 4.

Research publications for emulsions applications.

| Reference | Overview |

|---|---|

| Adeyemi et al. [8] | Experimental and numerical analysis of the emulsification of oil droplets in water with ultrasound |

| Adeyemi et al. [9] | Study of US assisted coalescence of water droplets in oil including techno-economic assessment |

| Adeyemi et al. [7] | Effect of various parameters on the acoustic pressure and coalescence time of water droplets in oil phase |

| Sadatshojaie et al. [84] | Study of US treatment for separation of medium gravity crude oil emulsions |

| Ronchi et al. [83] | Application of a US-assisted technique for removing oil from oily water without demulsifiers using Raschig rings |

| Luo et al. [57] | Effect of US parameters on emulsion separation with different physical properties |

| Lim et al. [51] | Study of the effect of US waves amplitude on the demulsification of crude emulsions at different temperatures |

| Vahdanikia et al. [94] | Study of the simultaneous influence of US waves and microorganisms on the stability of w/o emulsions |

| Atehortua et al. [21] | Use of a high frequency ultrasonic standing wave coalescence chamber to separate water in crude oil emulsions |

| Xu et al. [101] | Study of demulsification/dehydration for crude oil using US waves |

| Luo et al. [54] | Study of the application range and optimal parameters for separating water-in-oil (W/O) emulsions using ultrasonic standing waves |

| Khajehesamedini et al. [43] | Study of the feasibility of using low-frequency ultrasonic waves to reduce chemical demulsifiers consumption in the pretreatment of crude oil |

| Pedrotti et al. [76] | Development of an automated system for mapping and evaluating the acoustic intensity distribution for demulsification efficiency measurements |

| Yi et al. [103] | Study of demulsification using a combined treatment of US and chemical demulsifier |

| Antes et al. [18] | Comprehensive study for the evaluation of US frequency effect on demulsification of crude oil emulsions |

| Hamidi et al. [33 ] | Study of US effect on brine-oil interfaces (emulsion) in a reservoir using Hele-Shaw model |

| Antes et al. [19] | Study on the feasibility of indirect application of low frequency US for demulsification of crude oil without using chemical demulsifiers |

Numerical assessments of the coalescence of water droplets in water-in-oil emulsions and oil droplets in oil-in-water emulsions addressing the effect of various parameters on the acoustic pressure and coalescence time were considered. For the coalescence of water in W/O emulsions, the numerical simulation provided acceptable results, and the experimental validation showed that the coalescence time decreased within the range of interfacial tensions. The cause for this decrease was considered to be because lower interfacial tension produces more stable emulsions. Consequently, at lower interface tension between water and crude oil, higher resistance to the coalescence of the droplets due to improved emulsion stability was observed (Adeyemi et al. [7]). In the case of oil droplets in O/W emulsions, numerical simulations accurately modeling both trend and magnitude of the derived acoustic pressure data were obtained. The experimental results also showed the influence of ultrasonication on different variables. As the power and frequency increased, smaller size bubbles were obtained, and the catastrophic break up became more intense obtaining higher Weber numbers, thus, showing signs of improved emulsification (Adeyemi et al. [8]). An emulsion separation technique comparison was also carried out between US, electrostatic and microwave assisted technologies. US-assisted separation confirmed lower coalescence time with growing interfacial tension. Additionally, ultrasound proved the most potential in energy and economic savings, and the best option to be used as a standalone technique or in synergy with other techniques for emulsion separation, same as for applications in EOR (Adeyemi et al. [9]).

Sadatshojaie et al. [84] evaluated the performance of ultrasonic waves in demulsifying crude oil emulsions using a novel horn-type piezoelectric ultrasonic transducer. Tests proved that applying ultrasound caused water separation effectively and rapidly, even in the absence of any chemical (demulsifier). Nonetheless, in samples with initial water cuts of > 20 %, long irradiation times (approx. 5 min) resulted in a decline in water separation compared to two-minute tests.

4. US in oil Pre-Treatment processes

Recent work regarding the use of ultrasound waves for crude oil pre-treatment processes was revised. Nasri et al. [72] reported the use of ultrasonic waves to improve the desulfurization process of crude oil in Iran. The study included the effect analysis of different parameters, including ultrasound power, phase transfer agent (PTA) amount, catalyst amount, preheating temperature, and reaction time. The results indicated that increasing ultrasonic power, reaction time, and catalyst amount had positive influences on sulfur reduction, observing an optimal point in increasing PTA and preheating temperature. The first 10 min of the treatment were equivalent to three times in sulfur reduction of ultrasound assisted oxidative desulfurization (UAOD) process than that of the process during the latter 90 min. A similar study was performed by Fan et al. [25] in Saudi Arabia. The UAOD of Arabia extra light oil was performed at 60 °C and was able to remove 56.5 % of sulfur from the oil feedstock. The use of ultrasound instead of mechanical stirring significantly shortens the reaction time by over 80 % (from 80 to 15 min). Lin et al. [52] explored the effects of different parameters on desulfurization rate in UAOD. Parameters such as reaction temperature, reaction time, oxidant and demulsifier quantity were studied. It was proven that the ultrasonic treatment was able to improve the desulfurization efficiency by about 10 % with a power of 100 W and a frequency of 70 kHz. Lin also found that adding ultrasound can promote heterogeneous reactions, improve the activity of oxidants, and promote the degradation of macromolecular compounds.

Sinhmar et al. [89] combined an extractive and oxidative desulfurization approach based on ultrasound (US) and ultraviolet (UV) irradiations with additives using toluene and thiophene as representative fuel and model sulfur component, respectively. The desulfurization process was considerably improved when the combination of US and UV irradiation was applied rather than the standalone methods. This demonstrated that the combined US/UV approach coupled with use of oxidants and catalyst can promote the optimum conditions for a successful removal of thiophene.

Guida et al. (2022[30]) described a numerical approach to model ultrasonically induced cavitation (UIC) reactors including advanced computational fluid dynamics (CFD) models and bubble dynamics. This algorithm simulated the operation of an UIC reactor designed for the desulfurization of fuels using the oxidative (ODS) process.

Yi et al. [104] studied US assisted bio-desulfurization (BDS) using ultrasonic radiation to pre-oxidize the compounds before the BDS process. Findings revealed that the application of US before BDS procedure significantly improved its efficiency and allowed sulfur removal in shorter time.

5. US in oil recovery from Sludges, Wastewater, tar or oily sands

Some oil recovery or environmental applications to separate oil from waste for final deposition or treatment have been studied. There have also been an interesting application for recovery applications. Nevertheless, there is still a considerable lack of information especially on the pilot scale and field applications such as US-assisted treatment for oil recovery/removal from wastewater, oily sludge, tar or oily sands. Nevertheless, all the research found was mostly experimental.

On recent research in this field, the work of Luo et al. [55] was found. He studied the acoustic parameters and operating conditions that determine efficiency of oil recovery from oily sludge. The results exposed an improved efficiency of oil recovery from oily sludges using ultrasound and optimal parameters for increased desorption of oil from solid particles were found. Luo et al. attributed this improvement to the breakage that mechanical effects such as shock waves and micro jets due to acoustic cavitation can provoke on the hydrogen bonds between asphaltenes and solid particles, thus facilitating oil recovery from oily sludge.

Gao et al. [28] worked on the optimization of ultrasonic parameters based on pilot tests on oil removal from oily sludge. Removal rates of up to 60 % and oily sludge contents of 42 % were achieved, with the possibility of further improvement by the addition of surfactants. In 2015, Gao et al. [27] also investigated the removal of different components from oily sludge using ultrasonic treatment. Applying frequencies between 25 and 100 kHz, results showed that optimal ultrasonic washing performance in terms of oil extraction rate and efficiency was observed at 25 kHz. Another interesting finding from this experience was that ultrasonication could overcome high energy thresholds, resulting in an increase in the removal of asphaltenes and resins, with the removal of asphaltenes particularly affected by frequency.

Jin et al. [39] used a combined treatment of ultrasound waves, chemicals and heating to treat oil sludge from an oil storage tank and evaluated the effects of temperature, time, frequency, power, and other factors on oil recovery. Results showed that the combined US-assisted treatment reduced the oil content of oil sludge from 43.13 % to 1.01 %. Compared with traditional thermochemical cleaning, the oil recovery was higher with the combined treatment system.

As mentioned in previous sections, Zhang et al. [105] studied ultrasound treatment in conjunction with freeze/thaw process for treatment of oily sludge. The US-assisted process accomplished an acceptable performance by considering 80 % of oil recovered from wastewater with only 10 min of treatment.

Membrane ultrafiltration improved by using ultrasound to reduce membrane fouling process was studied by Borea et al. [22]. Results showed a significant reduction of membrane fouling rates at the higher membrane flux and lower US frequency applied, and improved removal of organic matter and turbidity if applied ultrasound at a higher frequency (130 kHz). These results prove the applicability of this combined process for the upgrading of membrane ultrafiltration and as an alternative option to conventional wastewater treatments.

Zhao et al. [107] studied the US-assisted synthesis of a new flocculant for remotion of the turbidity and oil from water, significantly improving flocculation performance.

In case of oil separation from oily sands, Fu et al. [26] proposed an extraction process assisted with a dual-frequency ultrasound technology for oil sand separation. A comparison of single frequency and dual frequency ultrasound treatment with surfactants was performed. Dual rate ultrasound stimulation yielded a considerably higher oil recovery rate of up to 95 % in comparison to single frequency treatment with short time of exposure. Therefore, dual-frequency ultrasound assisted surfactant extraction showed high efficiency and low resource consumption, proving to be an excellent option for the treatment of oily sands.

Another study performed by Ronchi et al. [83] proposed a methodology to remove oil from oily production water using low-frequency ultrasound. In his research, he investigated the application of low-frequency ultrasound waves to separate synthetic heavy crude oil-in-water using Raschig rings as most previous studies focused only on low viscosity dispersed phases (vegetable oils). The effects of frequency, temperature, US irradiation time, oil content of synthetic oil-in-water emulsions, and different materials were evaluated. High removal efficiencies of up to 76 % were obtained, especially using high frequencies and lower oil contents. These results show great promise of low-frequency US association of glass Raschig rings for treating the produced water to remove oil.

Zou et al. [109] proposed a new process for ultrasonic-assisted surfactant extraction of bitumen from Buton oil sands with recovery rates of over 90 % and promising applications.

Luo et al. [56] provided a summary review for oil extraction from oily sands including US-assisted methods. Even though most of their research and references dated back to a decade ago, they can be considered for background of applications and references for future studies, especially experimental experiences highlighted in their work.

6. Conclusions

From these summaries and reviews, we can conclude the following:

-

•

Ultrasonic stimulation is a promising technology that has proven to be highly efficient, environmentally friendly, and low cost for EOR by reducing the formation damage, unclogging perforation channels and increasing oil mobility. Nonetheless, there are numerous requirements for optimization.

-

•

The effect of ultrasound frequency, power output, irradiation time are considered some of the most influential variables on the efficiency of the treatment. However, the optimal values depend on several conditions, some of which have been partly identified and some of which have yet to be identified or studied further.

-

•

Numerical and mathematical studies are required to understand the ultrasound mechanisms of action and the effect on the reservoir and the fluids. Higher understanding and development of more comprehensive and enhanced US models and the ability to simulate the effect will allow the possibility to save valuable research time and resources, and to increase the success rate of ultrasound based and assisted applications.

-

•

The application of ultrasound waves in combination with other conventional technologies significantly boosts oil recovery rates and overall treatment efficiency in comparison to standalone treatments. For example, US-assisted chemical treatments can promote the use of greener alternatives of chemicals and surfactants, decrease chemical consumption, improve contact areas between the reagents and the reservoir, and reduce operation time and resources. More research studies are required in the evaluation of ultrasound integration with reagents alternatives in the industry.

-

•

The utilization of ultrasound waves for the treatment and separation of emulsions has also been proven. US parameters play an important role that can completely change the effect. Research showed that irradiation time can cause oil separation from the emulsion up to a peak or critical value, and further exposure over this critical value caused the opposite to the desired effect. Ultrasound frequency, power output and emulsion composition were also considered key parameters affecting the treatment performance.

-

•

The application of ultrasound waves has not been limited to EOR and emulsion treatment applications. US based technologies for the treatment of wastewater, sludge, oily and tar sands have been studied with successful cases and promising results.

-

•

Several experimental studies support the application of ultrasound technologies as a suitable EOR method, however, there is not enough research on field trials in order to optimize ultrasonic parameters. Conducting additional field studies is highly recommended to validate current experimental data, provide comprehensive understanding of the US effect in complex environments, evaluate existing technologies and equipment, and ultimately, develop accurate numerical and computational models of the mechanisms.

-

•

Additional research studies of new treatment conditions such as the use of Raschig rings, temperature and salinity of the environment and how they affect the US effect are recommended for the future.

-

•

New research models need to be proposed as a combination of highly focused R&D projects, and comprehensive evawluation and trials of existing technologies.

CRediT authorship contribution statement

Jesus Mierez: . Murtadha J. AlTammar: Funding acquisition, Supervision, Writing – original draft. Khalid M. Alruwaili: Funding acquisition, Supervision. Rima T. Alfaraj: Funding acquisition, Project administration, Supervision.

Declaration of competing interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests: Jesus Ricardo Mierez reports financial support was provided by Rexonic Ultrasonics AG. Jesus Ricardo Mierez reports a relationship with Rexonic Ultrasonics AG that includes: employment..

Data availability

Data will be made available on request.

References

- 1.Abdulfatah H.K. SPE Annual Technical Conference and Exhibition. 2018. Application of Ultrasonic Waves in Enhancing Oil Recovery in Secondary Recovery Phase. [Google Scholar]

- 2.Abramov V.O., Abramova A.V., Bayazitov V.M., Marnosov A.V., Kuleshov S.P., Gerasin A.S. Selective ultrasonic treatment of perforation zones in horizontal oil wells for water cut reduction. Appl. Acoust. 2016;103:214–220. [Google Scholar]

- 3.Abramov V.O., Abramova A.V., Bayazitov V.M., Mullakaev M.S., Marnosov A.V., Ildiyakov A.V. Acoustic and sonochemical methods for altering the viscosity of oil during recovery and pipeline transportation. Ultrason. Sonochem. 2017;35:389–396. doi: 10.1016/j.ultsonch.2016.10.017. [DOI] [PubMed] [Google Scholar]

- 4.Abramov V.O., Mullakaev M.S., Abramova A.V., Esipov I.B., Mason T.J. Ultrasonic technology for enhanced oil recovery from failing oil wells and the equipment for its implementation. Ultrason. Sonochem. 2013;20(5):1289–1295. doi: 10.1016/j.ultsonch.2013.03.004. [DOI] [PubMed] [Google Scholar]

- 5.Abramova A., Abramov V., Bayazitov V., Gerasin A., Pashin D. Ultrasonic Technology for Enhanced Oil Recovery. Engineering. 2014;2014(6):177–184. [Google Scholar]

- 6.Adeyemi I., Meribout M., Khezzar L. (a). Recent developments, challenges, and prospects of ultrasound-assisted oil technologies. Ultrason. Sonochem. 2022;82 doi: 10.1016/j.ultsonch.2021.105902. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Adeyemi I., Meribout M., Khezzar L., Kharoua N., AlHammadi K. (b). Numerical assessment of ultrasound supported coalescence of water droplets in crude oil. Ultrason. Sonochem. 2022;88 doi: 10.1016/j.ultsonch.2022.106085. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Adeyemi I., Meribout M., Khezzar L., Kharoua N., AlHammadi K., Tiwari V. (a). Experimental and numerical analysis of the emulsification of oil droplets in water with high frequency focused ultrasound. Ultrason. Sonochem. 2023;99 doi: 10.1016/j.ultsonch.2023.106566. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Adeyemi I., Meribout M., Khezzar L., Kharoua N., AlHammadi K. (b). Techno-economic comparative assessment of the ultrasound, electrostatic and microwave supported coalescence of binary water droplets in crude oil. Ultrason. Sonochem. 2023;95 doi: 10.1016/j.ultsonch.2023.106402. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Agi A., Junin R., Chong A.S. (a). Intermittent ultrasonic wave to improve oil recovery. J. Pet. Sci. Eng. 2018;166:577–591. [Google Scholar]

- 11.Agi A., Junin R., Arsad A., Abbas A., Gbadamosi A., Azli N.B., Oseh J. Ultrasound-assisted weak-acid hydrolysis of crystalline starch nanoparticles for chemical enhanced oil recovery. Int. J. Biol. Macromol. 2020;148:1251–1271. doi: 10.1016/j.ijbiomac.2019.10.099. [DOI] [PubMed] [Google Scholar]

- 12.Agi A., Junin R., Jaafar M., Sidek M., Yakasai F., Gbadamosi A., Oseh J. (a). Laboratory evaluation to field application of ultrasound: A state-of-the art review on the effect of ultrasonication on enhanced oil recovery mechanisms. J. Ind. Eng. Chem. 2022;110:100–119. [Google Scholar]

- 13.Agi A., Junin R., Jaafar M., Amin N.A.S., Sidek M., Nyakuma B., Yakasai F., Gbadamosi A., Oseh J., Azli N. (b). Ultrasound-assisted nanofluid flooding to enhance heavy oil recovery in a simulated porous media. Arab. J. Chem. 2022;15 [Google Scholar]

- 14.Agi A., Junin R., Shirazi R., Afeez G., Yekeen N. (b). Comparative study of ultrasound assisted water and surfactant flooding. Journal of King Saud University - Eng. Sci. 2018 [Google Scholar]

- 15.Ainuddin A., Aziz N.A.A., Soom N.A.A.M. Condensate banking removal: study on ultrasonic amplitude effect. J. Pet. Explor. Prod. Technol. 2021;11:3559–3569. [Google Scholar]

- 16.Alhomadhi E., Amro M., Almobarky M. Experimental application of ultrasound waves to improved oil recovery during waterflooding. Journal of King Saud University - Engineering Sciences. 2014;26(1):103–110. [Google Scholar]

- 17.Aliev F., Mukhamatdinov I., Kemalov A. The influence of ultrasound waves on rheological and physico-chemical properties of extra heavy oil from “ASHALCHA” field. International Multidisciplinary Scientific GeoConference: SGEM. 2017;17:941–948. [Google Scholar]

- 18.Antes F.G., Diehl L.O., Pereira J.S.F., Guimarães R.C.L., Guarnieri R.A., Ferreira B.M.S., Flores E.M.M. Effect of ultrasonic frequency on separation of water from heavy crude oil emulsion using ultrasonic baths. Ultrason. Sonochem. 2017;35:541–546. doi: 10.1016/j.ultsonch.2016.03.031. [DOI] [PubMed] [Google Scholar]

- 19.Antes F.G., Diehl L.O., Pereira J.S.F., Guimarães R.C.L., Guarnieri R.A., Ferreira B.M.S., Flores E.M.M. Feasibility of low frequency ultrasound for water removal from crude oil emulsions. Ultrason. Sonochem. 2015;25:70–75. doi: 10.1016/j.ultsonch.2015.01.003. [DOI] [PubMed] [Google Scholar]

- 20.Arabzadeh H., Amani M. Application of a novel ultrasonic technology to improve oil recovery with an environmental viewpoint. J. Pet. Environ. Biotechnol. 2017;08(02) [Google Scholar]

- 21.Atehortúa C.M.G., Pérez N., Andrade M.A.B., Pereira L.O.V., Adamowski J.C. Water-in-oil emulsions separation using an ultrasonic standing wave coalescence chamber. Ultrason. Sonochem. 2019;57:57–61. doi: 10.1016/j.ultsonch.2019.04.043. [DOI] [PubMed] [Google Scholar]

- 22.Borea L., Naddeo V., Shalaby M.S., Zarra T., Belgiorno V., Abdalla H., Shaban A.M. Wastewater treatment by membrane ultrafiltration enhanced with ultrasound: Effect of membrane flux and ultrasonic frequency. Ultrasonics. 2018;83:42–47. doi: 10.1016/j.ultras.2017.06.013. [DOI] [PubMed] [Google Scholar]

- 23.Chang, C. L. S., Spenger, O., Amran, A., M Khalil, M. I., M Ariffin, M. H., and Balakrishnan, D. (2019). First Application of Ultrasonic Technology in South East Asia: Breakthrough Case Study in Field T - Opening Doors for Alternative Stimulation Methods. SPE/IATMI Asia Pacific Oil and Gas Conference and Exhibition.

- 24.Cui J., Zhang Z., Liu X., Liu L., Peng J. Analysis of the viscosity reduction of crude oil with nano-Ni catalyst by acoustic cavitation. Fuel. 2020;275 [Google Scholar]

- 25.Fan J., Chen A., Saxena S., Vedachalam S., Dalai A.K., Zhang W., Roberts W.L. Ultrasound-assisted oxidative desulfurization of Arabian extra light oil (AXL) with molecular characterization of the sulfur compounds. Fuel. 2021;305 [Google Scholar]

- 26.Fu L., Zhang G., Ge J., Liao K., He Y., Wang X., Li H. Study on dual-frequency ultrasounds assisted surfactant extraction of oil sands. Fuel Process. Technol. 2017;167:146–152. [Google Scholar]

- 27.Gao Y., Ding R., Wu S., Wu Y., Zhang Y., Yang M. Influence of ultrasonic waves on the removal of different oil components from oily sludge. Environ. Technol. 2015;36(14):1771–1775. doi: 10.1080/09593330.2015.1010594. [DOI] [PubMed] [Google Scholar]

- 28.Gao Y.-X., Ding R., Chen X., Gong Z.-B., Zhang Y., Yang M. Ultrasonic washing for oily sludge treatment in pilot scale. Ultrasonics. 2018;90:1–4. doi: 10.1016/j.ultras.2018.05.013. [DOI] [PubMed] [Google Scholar]

- 29.Ghamartale A., Escrochi M., Riazi M., Faghih A. Experimental investigation of ultrasonic treatment effectiveness on pore structure. Ultrasonics. 2018 doi: 10.1016/j.ultsonch.2018.10.002. Sonochemistry. [DOI] [PubMed] [Google Scholar]

- 30.Guida P., et al. Numerical model of an ultrasonically induced cavitation reactor and application to heavy oil processing. Chemical Engineering Journal Advances. 2022;12 [Google Scholar]

- 31.Guo, X., Du, Z., and Li, Z. (2010). Computer Modeling and Simulation of High Frequency Vibration Recovery Enhancement Technology in Low-Permeability Reservoirs. Proceedings of Trinidad and Tobago Energy Resources Conference.

- 32.Hamidi H., et al. Recent applications of ultrasonic waves in improved oil recovery: A review of techniques and results. Ultrasonics. 2021;110 doi: 10.1016/j.ultras.2020.106288. [DOI] [PubMed] [Google Scholar]

- 33.Hamidi H., Mohammadian E., Asadullah M., Azdarpour A., Rafati R. (a). Effect of ultrasound radiation duration on emulsification and demulsification of paraffin oil and surfactant solution/brine using Hele-shaw models. Ultrason. Sonochem. 2015;26:428–436. doi: 10.1016/j.ultsonch.2015.01.009. [DOI] [PubMed] [Google Scholar]

- 34.Hamidi H., Mohammadian E., Rafati R., Azdarpour A., Ing J. (b). The effect of ultrasonic waves on the phase behavior of a surfactant–brine–oil system. Colloids Surf A Physicochem Eng Asp. 2015;482:27–33. [Google Scholar]

- 35.Hamidi H., Mohammadian E., Junin R., Rafati R., Manan M., Azdarpour A., Junid M. A technique for evaluating the oil/heavy-oil viscosity changes under ultrasound in a simulated porous medium. Ultrasonics. 2014;54(2):655–662. doi: 10.1016/j.ultras.2013.09.006. [DOI] [PubMed] [Google Scholar]

- 36.Hamidi H., Sharifi Haddad A., Mohammadian E., Rafati R., Azdarpour A., Ghahri P., Zink A. Ultrasound-assisted CO 2 flooding to improve oil recovery. Ultrason. Sonochem. 2017;35:243–250. doi: 10.1016/j.ultsonch.2016.09.026. [DOI] [PubMed] [Google Scholar]

- 37.He S., Tan X., Hu X., Gao Y. Effect of ultrasound on oil recovery from crude oil containing sludge. Environ. Technol. 2018:1–7. doi: 10.1080/09593330.2017.1422553. [DOI] [PubMed] [Google Scholar]

- 38.Hua Q. Experimental studies on viscosity reduction of heavy crude oil by ultrasonic irradiation. Acoust. Phys. 2020;66(5):495–500. [Google Scholar]

- 39.Jin Y., Zheng X., Chu X., Chi Y., Yan J., Cen K. Oil recovery from oil sludge through combined ultrasound and thermochemical cleaning treatment. Ind. Eng. Chem. Res. 2012;51(27):9213–9217. [Google Scholar]

- 40.Kamari A., Nikookar M., Hemmati-Sarapardeh A., Sahranavard L., and Mohammadi A.H. (2015). Screening of potential application of EOR processes in a naturally fractured oil reservoir. Enhanced oil recovery, chapter 11. Nova Science Publishers, Hauppauge.

- 41.Kang P.S., Lim J.S., Huh C. Screening criteria and considerations of offshore enhanced oil recovery. Energies. 2016;9(1):44. [Google Scholar]

- 42.Karami S., Saeedi Dehaghani A.H., Mousavi H.S., S. a. Condensate blockage removal using microwave and ultrasonic waves: Discussion on rock mechanical and electrical properties. J. Pet. Sci. Eng. 2020;107309 [Google Scholar]

- 43.Khajehesamedini A., Sadatshojaie A., Parvasi P., Reza Rahimpour M., Mehdi Naserimojarad M. Experimental and theoretical study of crude oil pretreatment using low-frequency ultrasonic waves. Ultrason. Sonochem. 2018;48:383–395. doi: 10.1016/j.ultsonch.2018.05.032. [DOI] [PubMed] [Google Scholar]

- 44.Khan N., Pu C., Li X., He Y., Zhang L., Jing C. (a). Permeability recovery of damaged water sensitive core using ultrasonic waves. Ultrason. Sonochem. 2017;38:381–389. doi: 10.1016/j.ultsonch.2017.03.034. [DOI] [PubMed] [Google Scholar]

- 45.Khan N., Pu C., Xu L., Lei Z. (b). Inorganic plugs removal using ultrasonic waves. IOP Conference Series: Earth and Environmental Science. 2017;59 [Google Scholar]

- 46.Khan N., Pu J., Pu C., Li X., Zhang L., Gu X., Zheng H. (c). Comparison of acidizing and ultrasonic waves, and their synergetic effect for the mitigation of inorganic plugs. Energy Fuel. 2017;31(10):11134–11145. [Google Scholar]

- 47.Khan N., Pu J., Pu C., Xu H., Gu X., Lei Z., Ullah R. Experimental and mechanism study: partially hydrolyzed polyacrylamide gel degradation and deplugging via ultrasonic waves and chemical agents. Ultrason. Sonochem. 2019;56:350–360. doi: 10.1016/j.ultsonch.2019.04.018. [DOI] [PubMed] [Google Scholar]

- 48.Kunanz H., Wolfel S. Scale Removal with Ultrasonic Waves. SPE International Oilfield Scale Conference and Exhibition. 2014;5/14 [Google Scholar]

- 49.Li X., et al. Experimental research on the effect of ultrasonic waves on the adsorption, desorption, and characteristics of shale gas. ACS Omega. 2021;6(26):17002–17018. doi: 10.1021/acsomega.1c02018. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 50.Li X., Pu C., Chen X., Huang F., Zheng H. Study on frequency optimization and mechanism of ultrasonic waves assisting water flooding in low-permeability reservoirs. Ultrason. Sonochem. 2020;70 doi: 10.1016/j.ultsonch.2020.105291. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Lim C.H., Sulaiman S.A., Japper-Jaafar A., Bhaskoro P.T. Study on the effect of ultrasonic wave amplitude on de-emulsification of crude oil to enhance production process. IOP Conference Series: Materials Science and Engineering. 2020;863 [Google Scholar]

- 52.Lin Y., Feng L., Li X., Chen Y., Yin G., Zhou W. Study on ultrasound-assisted oxidative desulfurization for crude oil. Ultrason. Sonochem. 2019;63 doi: 10.1016/j.ultsonch.2019.104946. [DOI] [PubMed] [Google Scholar]

- 53.Lins T.S., Pisoler G., Druzian G.T., Negris L., Decote P.A.P., Vicente M.A., Flores E.M.M., Santos M.F.P. Base oil recovery from waste lubricant oil by polar solvent extraction intensified by ultrasound. Environ. Sci. Pollut. Res. 2021;28:66000–66011. doi: 10.1007/s11356-021-15582-y. [DOI] [PubMed] [Google Scholar]

- 54.Luo X., Gong H., Cao J., Yin H., Yan Y., He L. Enhanced separation of water-in-oil emulsions using ultrasonic standing waves. Chem. Eng. Sci. 2019;203:285–292. [Google Scholar]

- 55.Luo X., Gong H., He Z., Zhang P., He L. Research on mechanism and characteristics of oil recovery from oily sludge in ultrasonic fields. J. Hazard. Mater. 2020;399 doi: 10.1016/j.jhazmat.2020.123137. [DOI] [PubMed] [Google Scholar]

- 56.Luo X., Gong H., He Z., Zhang P., He L. Recent advances in applications of power ultrasound for petroleum industry. Ultrason. Sonochem. 2021;70 doi: 10.1016/j.ultsonch.2020.105337. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 57.Luo X., Gong H., Yin H., He Z., He L. (b). Optimization of acoustic parameters for ultrasonic separation of emulsions with different physical properties. Ultrason. Sonochem. 2020;68 doi: 10.1016/j.ultsonch.2020.105221. [DOI] [PubMed] [Google Scholar]

- 58.Mo L., Sun W., Jiang S., Zhao X., Ma H., Liu B., Feng L. Removal of colloidal precipitation plugging with high-power ultrasound. Ultrason. Sonochem. 2020;69 doi: 10.1016/j.ultsonch.2020.105259. [DOI] [PubMed] [Google Scholar]

- 59.Mohammadian E., Junin R., Rahmani O., Idris A.K. Effects of sonication radiation on oil recovery by ultrasonic waves stimulated water-flooding. Ultrasonics. 2013;53(2):607–614. doi: 10.1016/j.ultras.2012.10.006. [DOI] [PubMed] [Google Scholar]

- 60.Mohammadian E., Parak M., Babakhani P. The effects of properties of waves on the recovery of ultrasonic stimulated waterflooding. Pet. Sci. Technol. 2014;32(8):1000–1008. [Google Scholar]

- 61.Mohammadian E., Shirazi M.A., Idris A.K. SPE Asia Pacific Oil and Gas Conference and Exhibition. 2011. Enhancing oil recovery through application of ultrasonic assisted waterflooding. [Google Scholar]

- 62.Mohsin M., Meribout M. An extended model for ultrasonic-based enhanced oil recovery with experimental validation. Ultrason. Sonochem. 2015;23:413–423. doi: 10.1016/j.ultsonch.2014.08.007. [DOI] [PubMed] [Google Scholar]

- 63.Mousavi S.M., Ramazani A., Najafi I., Davachi S.M. Effect of ultrasonic irradiation on rheological properties of asphaltenic crude oils. Pet. Sci. 2012;9(1):82–88. [Google Scholar]

- 64.Mullakaev M.S., Abramov V.O., Abramova A.V. (a). Development of ultrasonic equipment and technology for well stimulation and enhanced oil recovery. J. Pet. Sci. Eng. 2015;125:201–208. [Google Scholar]

- 65.Mullakaev M.S., Abramov V.O., Abramova A.V. (a). Ultrasonic automated oil well complex and technology for enhancing marginal well productivity and heavy oil recovery. J. Pet. Sci. Eng. 2017;159:1–7. [Google Scholar]

- 66.Mullakaev M.S., Abramov V.O., Abramova A.V. (b). Ultrasonic piezoceramic module and technology for stimulating low-productivity wells. J. Pet. Sci. Eng. 2017;158:529–534. [Google Scholar]

- 67.Mullakaev M.S., Abramov V.O., Prachkin V.G. (b). Development of a combined technology and ultrasonic scheme for stimulation of oil recovery. Chem. Pet. Eng. 2015;51(3–4):237–242. [Google Scholar]

- 68.Mullakaev M.S., Volkova G.I., Gradov O.M. (c). Effect of ultrasound on the viscosity-temperature properties of crude oils of various compositions. Theor. Found. Chem. Eng. 2015;49(3):287–296. [Google Scholar]

- 69.Naderi K., Babadagli T. Influence of intensity and frequency of ultrasonic waves on capillary interaction and oil recovery from different rock types. Ultrason. Sonochem. 2010;17(3):500–508. doi: 10.1016/j.ultsonch.2009.10.022. [DOI] [PubMed] [Google Scholar]

- 70.Naderi K., Babadagli T. Visual analysis of immiscible displacement processes in porous media under ultrasound effect. Phys. Rev. E. 2011;83(5) doi: 10.1103/PhysRevE.83.056323. [DOI] [PubMed] [Google Scholar]

- 71.Najafi I. SPE Annual Technical Conference and Exhibition. 2010. A mathematical analysis of the mechanism of ultrasonic induced fluid percolation in porous media: part I. [Google Scholar]

- 72.Nasri Z., Ghahremani H., Nasri Z., Eikani M.H. Ultrasound-assisted oxidative desulfurization (UAOD) of Iranian heavy crude oil: Investigation of process variables. J. Pet. Sci. Eng. 2021;204 [Google Scholar]

- 73.Otumudia E., Hamidi H., Jadhawar P., Wu K. (a). Effects of reservoir rock pore geometries and ultrasonic parameters on the removal of asphaltene deposition under ultrasonic waves. Ultrason. Sonochem. 2022;83 doi: 10.1016/j.ultsonch.2022.105949. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 74.Otumudia E., Hamidi H., Jadhawar P., Wu K. (b). The utilization of ultrasound for improving oil recovery and formation damage remediation in petroleum reservoirs: review of most recent researches. Energies. 2022;15:4906. [Google Scholar]

- 75.Otumudia E., Hamidi H., Jadhawar P., Wu K. Effects of ultrasound on the removal of emulsion plugging in oil reservoirs. Colloids Surf A Physicochem Eng Asp. 2023;676 [Google Scholar]

- 76.Pedrotti M.F., Enders M.S.P., Pereira L.S.F., Mesko M.F., Flores E.M.M., Bizzi C.A. Intensification of ultrasonic-assisted crude oil demulsification based on acoustic field distribution data. Ultrason. Sonochem. 2018;40:53–59. doi: 10.1016/j.ultsonch.2017.03.056. [DOI] [PubMed] [Google Scholar]

- 77.Pu C., Shi D., Zhao S., Xu H., Shen H. Technology of removing near wellbore inorganic scale damage by high power ultrasonic treatment. Pet. Explor. Dev. 2011;38(2):243–248. [Google Scholar]

- 78.Qajar J., Razavifar M., Riazi M. A mechanistic study of the synergistic and counter effects of ultrasonic and solvent treatment on the rheology and asphaltene structure of heavy crude oil. Chemical Engineering and Processing – Process Intensification. 2024;195 [Google Scholar]

- 79.Rahimi, M. A. et al. (2017). Effect of ultrasonic irradiation treatment on rheological behavior of extra heavy crude oil: A solution method for transportation improvement, Can. J. Chem. Eng., 95(1), 83-91, 01/01, 2020/04.

- 80.Razavifar M., Qajar J. Experimental investigation of the ultrasonic wave effects on the viscosity and thermal behaviour of an asphaltenic crude oil. Chemical Engineering and Processing - Process Intensification. 2020;107964 [Google Scholar]

- 81.Rezaei Dehshibi R., Mohebbi A., Riazi M., Danafar F. Visualization study of the effects of oil type and model geometry on oil recovery under ultrasonic irradiation in a glass micro-model. Fuel. 2019;239:709–716. [Google Scholar]

- 82.Rezaei Dehshibi R., Mohebbi A., Riazi M., Niakousari M. Experimental investigation on the effect of ultrasonic waves on reducing asphaltene deposition and improving oil recovery under temperature control. Ultrason. Sonochem. 2018;45:204–212. doi: 10.1016/j.ultsonch.2018.03.023. [DOI] [PubMed] [Google Scholar]

- 83.Ronchi R.P., Negris L., Melo B.N., Pereira L.S.F., Vicente M.A., Flores E.M.M., de Santos M., F. p. Removal of oil from synthetic heavy crude oil-in-water emulsions by the association of glass Raschig rings and ultrasound. J. Dispers. Sci. Technol. 2020:1–11. [Google Scholar]

- 84.Sadatshojaie A., Wood D.A., Mohammad Jokar S., Reza Rahimpour M. Applying ultrasonic fields to separate water contained in medium-gravity crude oil emulsions and determining crude oil adhesion coefficients. Ultrason. Sonochem. 2021;70 doi: 10.1016/j.ultsonch.2020.105303. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 85.Salehzadeh M., Akherati A., Ameli F., Dabir B. Experimental study of ultrasonic radiation on growth kinetic of asphaltene aggregation and deposition. Can. J. Chem. Eng. 2016;94(11):2202–2209. [Google Scholar]

- 86.Shafiai, S. H. and Gohari, A. (2020). Conventional and electrical EOR review: the development trend of ultrasonic application in EOR. Journal of Petroleum Exploration and Production Technology.

- 87.Shi C., Yang W., Chen J., Sun X., Chen W., An H., Pei M. Application and mechanism of ultrasonic static mixer in heavy oil viscosity reduction. Ultrason. Sonochem. 2017;37:648–653. doi: 10.1016/j.ultsonch.2017.02.027. [DOI] [PubMed] [Google Scholar]

- 88.Lv S., Peng S., Zhang R., Guo Z., Du W., Zhang J., Chen G. Viscosity reduction of heavy oil by ultrasonic. Pet. Chem. 2020;60(9):998–1002. [Google Scholar]

- 89.Sinhmar P.S., Tiple A., Gogate P.R. Combined extractive and oxidative desulfurization approach based on ultrasound and ultraviolet irradiation with additives for obtaining clean fuel. Environ. Technol. Innov. 2021;22 [Google Scholar]

- 90.Taheri-Shakib J., Naderi H., Salimidelshad Y., Kazemzadeh E., Shekarifard A. Application of ultrasonic as a novel technology for removal of inorganic scales (KCl) in hydrocarbon reservoirs: An experimental approach. Ultrason. Sonochem. 2018;40:249–259. doi: 10.1016/j.ultsonch.2017.06.019. [DOI] [PubMed] [Google Scholar]

- 91.Taheri-Shakib J., Naderi H., Salimidelshad Y., Teymouri A., Shekarifard A. Using ultrasonic as a new approach for elimination of inorganic scales (NaCl): an experimental study. J. Pet. Explor. Prod. Technol. 2017;8(2):553–564. [Google Scholar]

- 92.Taherynia M.H., Fatemi Aghda S.M., Fahimifar A. Effects of ultrasonic waves on water imbibition into oil-wet carbonate reservoirs (a case study) Petrol. Sci. Technol. 2022:1–16. [Google Scholar]

- 93.Tahmasebi Boldaji R., Rajabi Kuyakhi H., Tahmasebi Boldaji N., Rajabzadeh M., Rashidi S., Torki M., Ghazanfari S. A comparative study of mathematical and ANFIS models to determine the effect of ultrasonic waves on the viscosity of crude oil. Petrol. Sci. Technol. 2022;40:150–165. [Google Scholar]

- 94.Vahdanikia N., Divandari H., Hemmati-Sarapardeh A., Menad N.A., Schaffie M., Ranjbar M. Integrating new emerging technologies for enhanced oil recovery: Ultrasonic, microorganism, and emulsion. J. Pet. Sci. Eng. 2020;192 [Google Scholar]

- 95.Wang H., Tian L., Zhang K., Liu Z., Huang C., Jiang L., Chai X. How is ultrasonic-assisted CO2 EOR to unlock oils from unconventional reservoirs? Sustainability. 2021;13:10010. [Google Scholar]

- 96.Wang Z., Huang J. Research on removing reservoir core water sensitivity using the method of ultrasound-chemical agent for enhanced oil recovery. Ultrason. Sonochem. 2018;42:754–758. doi: 10.1016/j.ultsonch.2017.12.046. [DOI] [PubMed] [Google Scholar]

- 97.Wang Z., Fang R., Guo H. Advances in ultrasonic production units for enhanced oil recovery in China. Ultrason. Sonochem. 2019;60 doi: 10.1016/j.ultsonch.2019.104791. [DOI] [PubMed] [Google Scholar]

- 98.Wang Z., Xu Y., Gu Y. Lithium niobate ultrasonic transducer design for Enhanced Oil Recovery. Ultrason. Sonochem. 2015;27:171–177. doi: 10.1016/j.ultsonch.2015.05.017. [DOI] [PubMed] [Google Scholar]

- 99.Wang Z., Zeng J., Song H., Li F. Research on ultrasonic excitation for the removal of drilling fluid plug, paraffin deposition plug, polymer plug and inorganic scale plug for near-well ultrasonic processing technology. Ultrason. Sonochem. 2017;36:162–167. doi: 10.1016/j.ultsonch.2016.11.026. [DOI] [PubMed] [Google Scholar]

- 100.Xu X., Bao T. Research on the removal of near-well blockage caused by asphaltene deposition using sonochemical method. Ultrason. Sonochem. 2019;64 doi: 10.1016/j.ultsonch.2019.104918. [DOI] [PubMed] [Google Scholar]

- 101.Xu X., Cao D., Liu J., Gao J., Wang X. Research on ultrasound-assisted demulsification / dehydration for crude oil. Ultrason. Sonochem. 2019;57:185–192. doi: 10.1016/j.ultsonch.2019.05.024. [DOI] [PubMed] [Google Scholar]

- 102.Yeh H.L., Juarez J.J. Ultrasound-enhanced diffusion and streaming of colloids in porous media. Exp. Therm Fluid Sci. 2021;121 [Google Scholar]

- 103.Yi M., Huang J., Wang L. Research on crude oil demulsification using the combined method of ultrasound and chemical demulsifier. J. Chem. 2017;2017:1–7. [Google Scholar]

- 104.Yi Z., Ma X., Song J., Yang X., Tang Q. Investigations in enhancement biodesulfurization of model compounds by ultrasound pre-oxidation. Ultrason. Sonochem. 2019;54:110–120. doi: 10.1016/j.ultsonch.2019.02.009. [DOI] [PubMed] [Google Scholar]

- 105.Zhang J., Li J., Thring R.W., Hu X., Song X. Oil recovery from refinery oily sludge via ultrasound and freeze/thaw. J. Hazard. Mater. 2012;203–204:195–203. doi: 10.1016/j.jhazmat.2011.12.016. [DOI] [PubMed] [Google Scholar]

- 106.Zhang X., Zang C., Ma H., Wang Z. Study on removing calcium carbonate plug from near wellbore by high-power ultrasonic treatment. Ultrason. Sonochem. 2019;62 doi: 10.1016/j.ultsonch.2019.03.006. [DOI] [PubMed] [Google Scholar]

- 107.Zhao C., Zheng H., Gao B., Liu Y., Zhai J., Zhang S., Xu B. Ultrasound-initiated synthesis of cationic polyacrylamide for oily wastewater treatment: Enhanced interaction between the flocculant and contaminants. Ultrason. Sonochem. 2018;42:31–41. doi: 10.1016/j.ultsonch.2017.11.006. [DOI] [PubMed] [Google Scholar]

- 108.Zhou L., Wang Z. A comparison study on the removal of paraffin wax deposition plugs by ultrasound treatment, chemical demulsifier and combination of ultrasound and chemical demulsifier. Pet. Sci. Technol. 2020:1532–2459. [Google Scholar]

- 109.Zou C., Zhao P., Ge T., Li D., Ye H., Huang G. Bitumen recovery from Buton oil sands using a surfactant under the effect of ultrasonic waves. Energy Sources Part A. 2016;38(2):270–276. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.