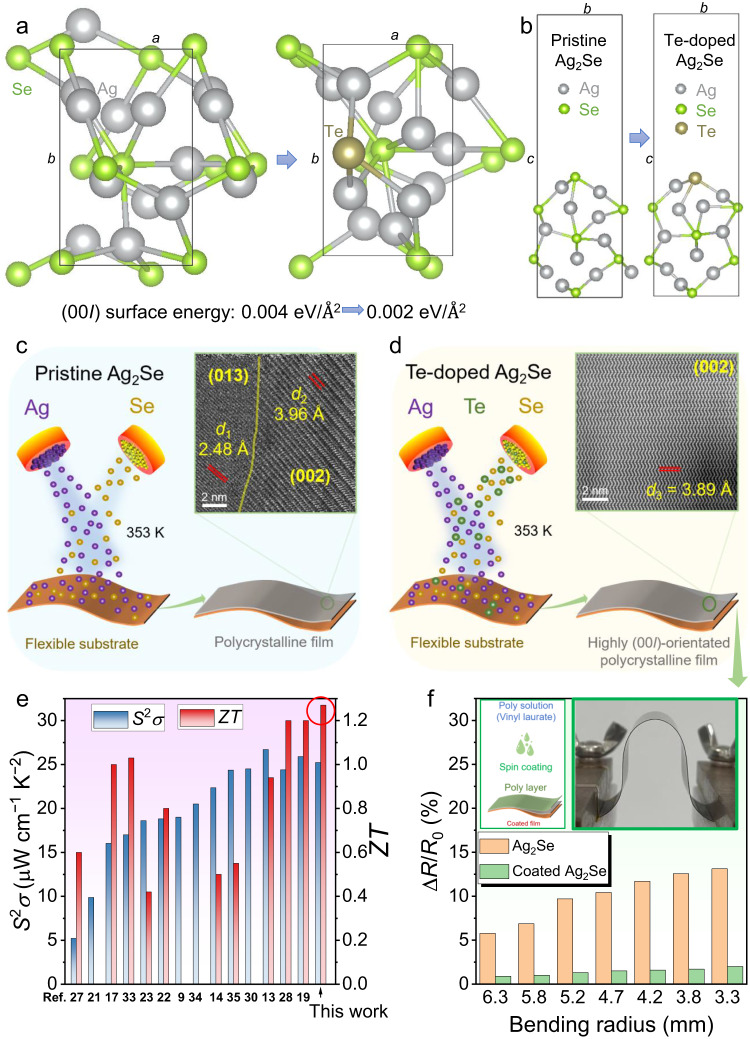

Fig. 1. Introduction of Ag2Se thin films with both high thermoelectric performance and flexibility by Te-doping-induced band and orientation engineering.

Unit cells of Ag2Se before and after Te-doping viewed along the (a) c- and (b) a-axis. Illustrations of fabricating Ag2Se thin films (c) without and (d) with Te-doping by a vacuum thermal co-evaporation method. The transmission electron microscopy (TEM) image in c indicates the polycrystalline feature of pristine Ag2Se thin film, and the TEM image in (d) indicates the highly (00l)-orientated feature of Te-doped Ag2Se thin film. e Comparison of power factor S2σ and dimensionless figure-of-merit ZT values between this work and reported works including printed Ag-Se-based thin film27, Ag2Se film on nylon membrane21, poly(3,4-ethylenedioxythiophene) (PEDOT)/Ag2Se/CuAgSe composite film17, printed β-Ag2Se33, Ag/Ag2Se composite film23, Ag2Se film on porous nylon membrane22, Ag1.8Se film9, Ag2.06Se film34, Ag2Se/Ag/CuAgSe composite film14, Ag/ Ag2Se composite film35, Ag-rich Ag2Se film30, Ag2Se/Se/polypyrrole (PPy) composite film13, Ag2Se film prepared by pulsed hybrid reactive magnetron sputtering (PHRMS)28, and microstructurally tailored β-Ag2Se thin film19 (from left to right). f Measured increased normalized resistance ΔR/R0 of Te-doped Ag2Se thin films with and without coating as a function of bending radius. The coating is composed of 90% poly(vinyl laurate) and 10% N-methylpyrrolidone. The insets show the illustration of the spin coating process (left) and the photo of testing the flexibility of the as-fabricated thin film (right).