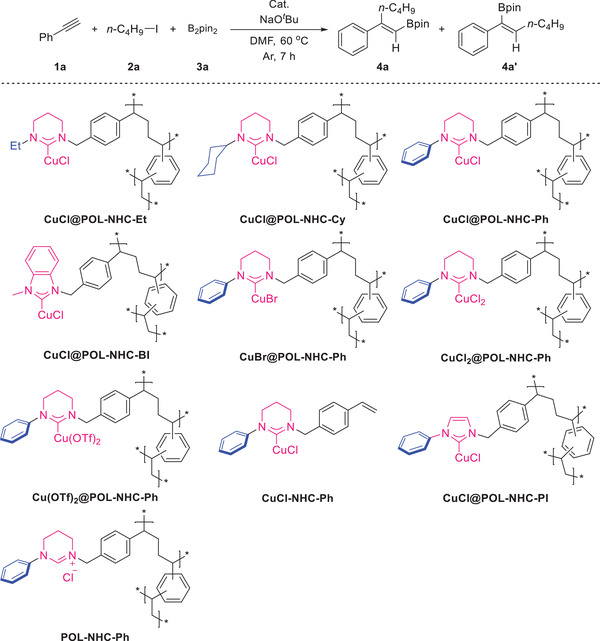

Table 1.

Optimization of reaction conditions.

| |||

|---|---|---|---|

| Entry a) | Catalyst | Yield (%) b) | Ratio of 4a:4a’ c) |

| 1 | CuCl@POL‐NHC‐Et | 74 | 93:7 |

| 2 | CuCl@POL‐NHC‐Cy | 80 | 99:1 |

| 3 | CuCl@POL‐NHC‐Ph | 88 | >99:1 |

| 4 | CuCl@POL‐NHC‐BI | 70 | 94:6 |

| 5 | Cu(OTf)2@POL‐NHC‐Ph | 38 | 96:4 |

| 6 | CuCl2@POL‐NHC‐Ph | 48 | >99:1 |

| 7 | CuBr@POL‐NHC‐Ph | trace | – |

| 8 d) | CuCl‐NHC‐Ph | trace | – |

| 9 | CuCl@POL‐NHC‐PI | 75 | >95:5 |

| 10 | POL‐NHC‐Ph | 0 | – |

Reaction conditions: 1a (0.5 mmol), 2a (2 equiv), 3a (1.5 equiv), NaO t Bu (1.5 equiv), [Cu]@POL‐NHC (20 mg), DMF (0.25 M), 60°C, 7 h;

Isolated yield;

Determined by using 1H NMR spectroscopy;

4 mol% CuCl‐NHC‐Ph. The conversion rate of NHC in [Cu]@POL‐NHC is shown in Table S4 (Supporting Information).