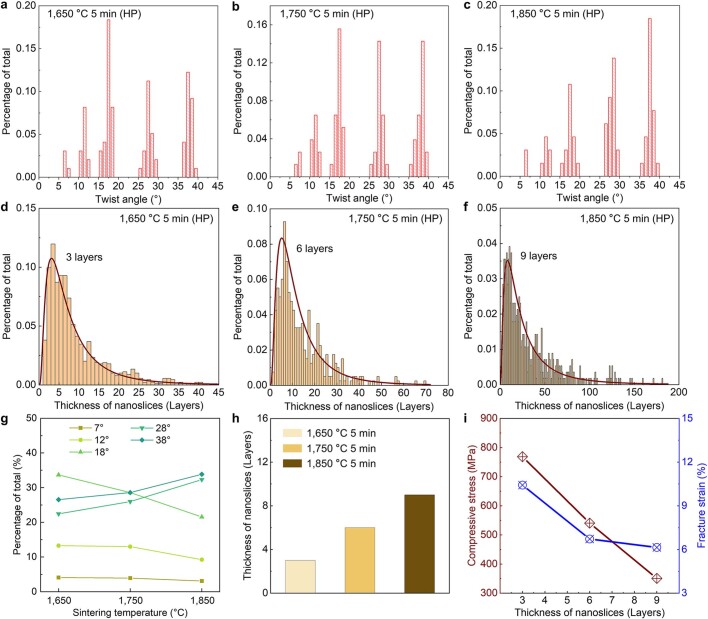

Extended Data Fig. 9. Statistical distribution of twist angles and nanoslice thickness, and the relationships between synthesis parameters, microstructure, and mechanical properties in hot-pressing (HP) sintered TS-BN ceramics.

a-c, Distribution of twist angles in the ceramics sintered at 1,650 °C (a), 1,750 °C (b), and 1,850 °C (c). The distribution of twist angle is similar as that of SPS sintered samples, concentrated around 38°, 28°, 18°, 12°, and 7°. d-f, Thickness of nanoslices in ceramics sintered at 1,650 °C (d), 1,750 °C (e), and 1,850 °C (f). g, Percentage variation of twist angles with sintering temperature. As the sintering temperature increases, the proportion of 27.8° and 38.2° gradually increased. h, Average thickness of nanoslices in ceramics sintered at different temperature. As the sintering temperature increases, the average thickness of nanoslices increases from 3 layers to 9 layers, which is slightly less than that of SPS sintered ceramics. i, Relationships between the nanoslice thickness and the strength/strain of TS-BN ceramics. With the nanoslice thickness increases, the strength and fracture strain of ceramics gradually decrease. The distribution of twist angles, the percentage change of twist angles, and the variation of nanoslice thickness with sintering temperature, as well as the relationship between nanoslice thickness and the strength/strain of hot-pressing sintered ceramics, are similar to the situation in SPS sintered ceramics. This shows that pressure, temperature, and holding time are the key factors controlling the microstructure and properties of TS-BN ceramics; effects of electronic current applied in SPS synthesis are negligible.