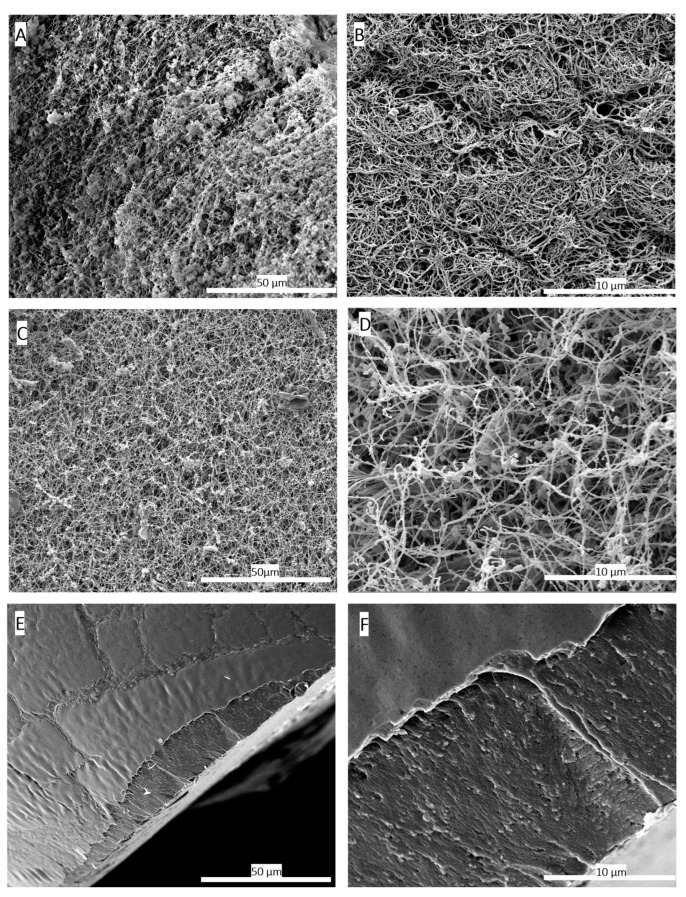

Figure 2.

Scanning electron microscopy (SEM) images comparing the 3D structure of fibrin networks in platelet lysate hydrogels (A,B) and aerogels (C,D), along with hydrogels dried conventionally in an oven at 37 °C (E,F). (A) SEM image of the hydrogel at a magnification of 1000×. (B) SEM image of the hydrogel at a magnification of 5000×, illustrating the formed fibrin network. (C) SEM image of the HPL aerogel at 1000× magnification. (D) SEM image of the HPL aerogel at 5000× magnification, confirming the preservation of the fibrin network’s structural integrity through the supercritical CO2-based shaping process. (E) SEM image of the hydrogel dried in an oven at 37 °C at a magnification of 1000×. (F) SEM images of hydrogels dried in an oven at 37 °C at a magnification of 5000×. These images highlight the adverse effects of conventional drying on the three-dimensional fibrin network structure, resulting in a flattened and non-porous fibrin structure. These findings provide conclusive evidence of the destructive impact of oven drying at 37 °C on the three-dimensional fibrin network, resulting in a flattened and non-porous structure.