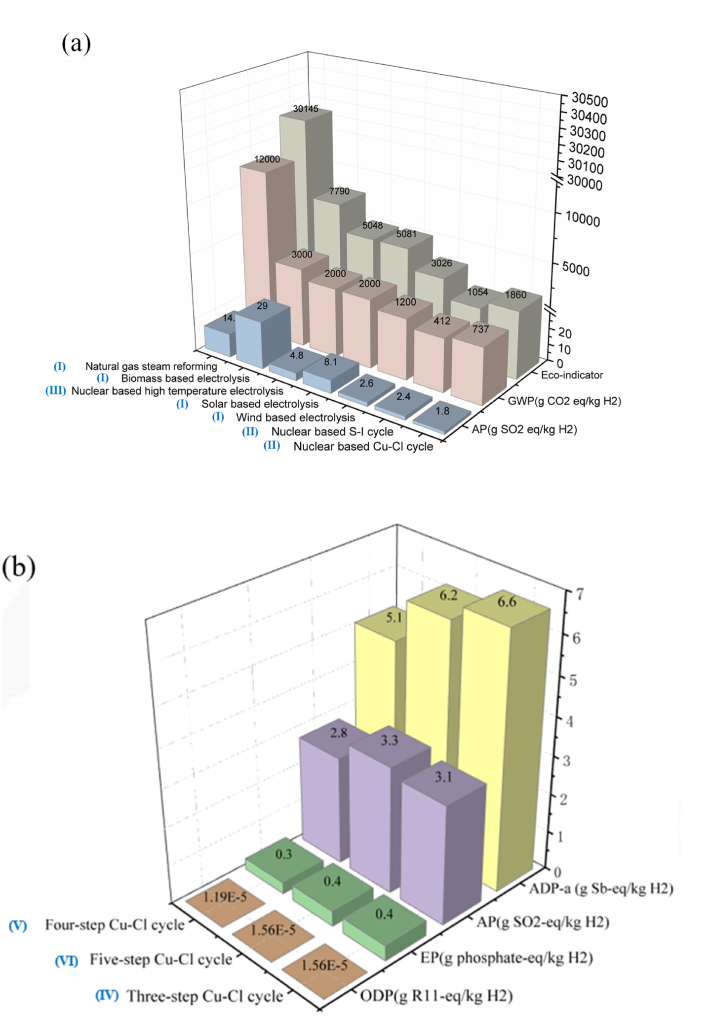

Fig. 5.

LCA analysis results of different sustainable hydrogen production technologies. (a) GWP, AP and Eco-indicator value; (b) ODP, EP, AP and ADP-a value [197] (AP: acidification potential; ADP-a: abiotic resource depletion potential; EP: eutrophication potential; GWP: global warming potential; ODP: ozone depletion potential). System assumptions: (Ⅰ) National Renewable Energy Laboratory provide GWP information for hydrogen produced by traditional natural gas steam reforming, wind and solar based electrolysis [196]. (Ⅱ) Plant capacity 3000 kg H2/day; overall inputs for 1 h of operation of hydrogen production plant (thermal energy 18.57 GJ; water 1125 kg); overall output for 1 h of operation of hydrogen production plant (hydrogen 1125 kg), heat exchanger efficiency (HHV) = 50% [198]. (Ⅲ) Nuclear based high temperature electrolysis plant requirement: electrical energy 200 MJ/kg H2, thermal energy 35 MJ/kg H2. Hydrogen production rate 7700 kg/h; plant capacity 600 MW [199]. (Ⅳ) Three-step Cu–Cl cycle hydrogen plant overall inputs: thermal energy 182.74 MJ/kg H2; electrical energy 67.15 MJ/kg H2; water 9 kg/kg H2. Plant outputs: oxygen 8 kg/kg H2; hydrogen 1 kg [197]. (Ⅴ) Four-step Cu–Cl cycle hydrogen plant overall inputs: thermal energy 161.05 MJ/kg H2; electrical energy 67.15 MJ/kg H2; water 9 kg/kg H2. Plant outputs: oxygen 8 kg/kg H2; hydrogen 1 kg [197]. (Ⅵ) Five-step Cu–Cl cycle hydrogen plant overall inputs: thermal energy 195.7 MJ/kg H2; electrical energy 50.3 MJ/kg H2; water 9 kg/kg H2. Plant outputs: oxygen 8 kg/kg H2; hydrogen 1 kg. Plant capacity for three Cu–Cl cycles: 125,000 kg H2/day. Plant lifetime: 60 years [197].