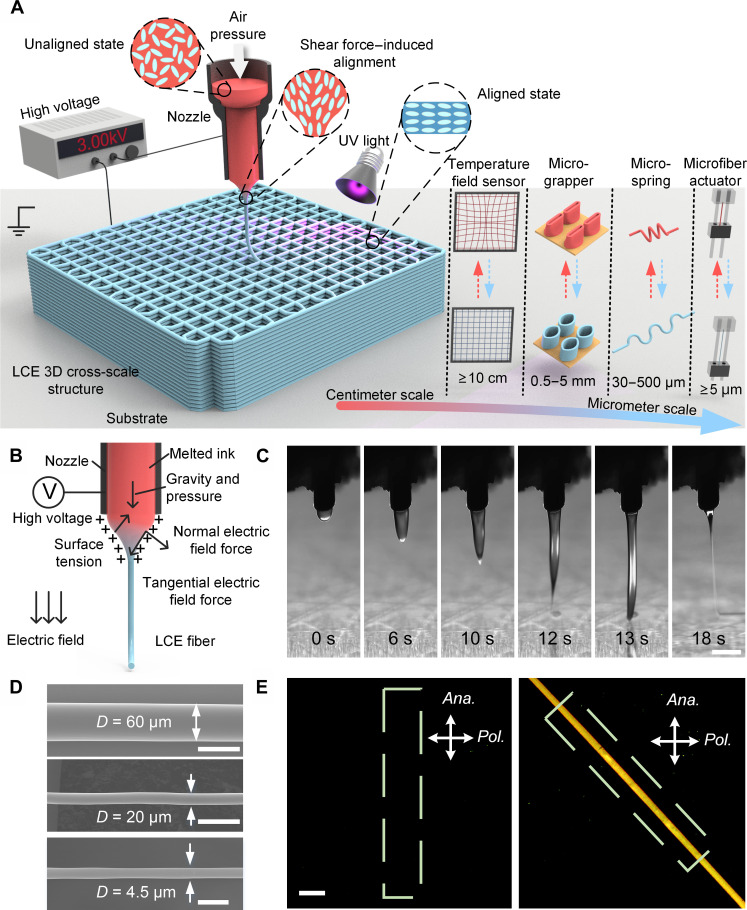

Fig. 1. The 3D MEW-printed LCE microfibers.

(A) Schematic illustration of 3D MEW-printed LCE microfibers and 3D cross-scale structures. A high voltage of 2 to 3 kV was applied between a metal nozzle and the substrate. The melted LCE ink in an unaligned state was driven out of the nozzle to form Taylor cones and fine jets. The powerful shear force inside the Taylor cones gradually aligned and oriented the mesogens of LCE microfibers, which were deposited along preprogrammed paths on the substrate to construct various cross-scale 3D structures. (B) Schematic illustration of the generation of the shear force inside the Taylor cone during the MEW process. (C) Dynamic formation process of Taylor cones and stable LCE microfibers during the MEW process. Scale bar, 500 μm. (D) SEM images of MEW-printed LCE microfibers with different diameters. Scale bars, 50 μm (D = 60 μm and D = 20 μm) and 10 μm (D = 4.5 μm). (E) POM images of the LCE microfibers with aligned mesogens at two different angles relative to the analyzer. Scale bar, 100 μm.