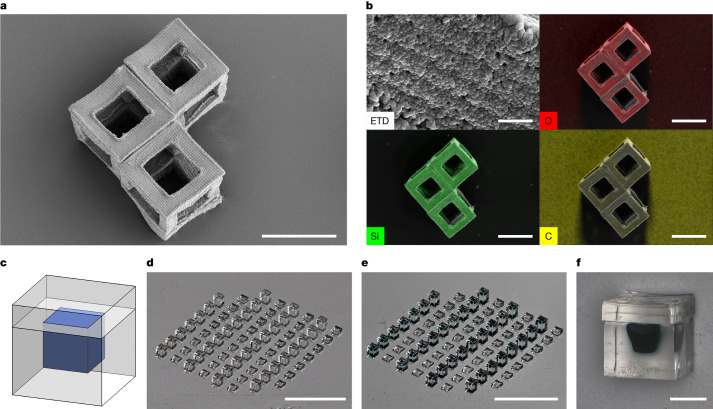

Fig. 4. Particles fabricated via r2rCLIP enable a range of applications including ceramic particles and drug delivery.

a, Hollow ceramic cubes formed from pyrolysis of HDDA–ceramic mix resin. b, EDS analysis of the surface of a hollow ceramic cube (top left) showing uniform distribution of silicon and oxygen, quantified as 30 ± 1% silicon, 35 ± 1% oxygen and 35 ± 2% carbon by normalized mass. Elemental distribution of O, Si and C (top right, bottom left and bottom right, respectively) overlaid on secondary electron image of the hollow cubes. c,d, Drug-delivery cubes may be designed to meet the goals of payload volume, release profile, material and so on (c) and fabricated via r2rCLIP (d) (PEGDMA550 material, for example). e,f, Devices may be then filled, as demonstrated with trypan blue dye for visualization (e), and subsequently capped (f). Scale bars, 100 µm (a), 5 µm (b, top left), 100 µm (b, other three images), 3 mm (d,e), 200 µm (f).