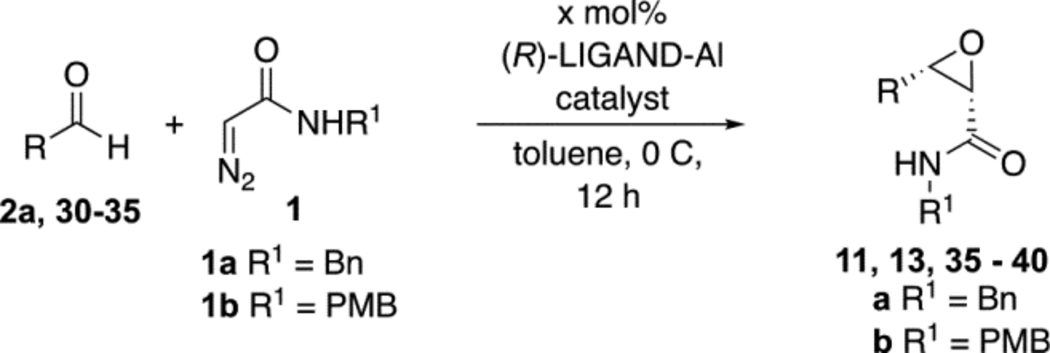

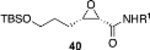

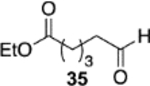

Table 3.

Epoxidation of Aliphatic Aldehydes with VANOL and VAPOL Aluminum Catalystsa

| ||||||

|---|---|---|---|---|---|---|

| aldehyde | epoxide | Ligand | catalyst (mol%) | R1 | % yield epoxideb | %ee epoxidec |

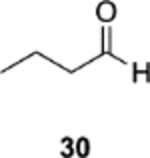

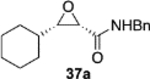

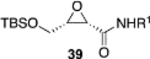

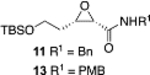

|

|

(S)-VAPOL | 5 | Bn | 62 | −89 d |

| (R)-VANOL | 5 | Bn | 74 | 92 | ||

| (S)-VANOL | 10 | Bn | 84 | −95 d | ||

| (S)-VANOL | 10 | Bn | 24 | −86 d,e | ||

| (S)-VAPOL | 5 | PMB | 50 | −86 d | ||

| (R)-VAPOL | 10 | PMB | 79 | 94 | ||

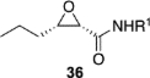

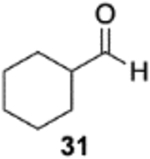

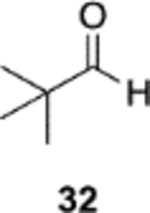

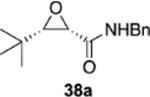

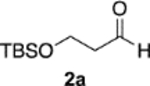

|

|

(S)-VAPOL | 5 | Bn | 68 | −88 d |

| (R)-VAPOL | 10 | Bn | 81 | 94 | ||

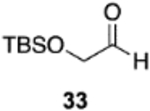

|

|

(R)-VAPOL | 10 | Bn | 50 | 99 |

|

|

(S)-VAPOL | 5 | Bn | 78 | −56d |

| (R)-VAPOL | 10 | Bn | 73 | 58 | ||

| (S)-VAPOL | 5 | PMB | 73 | −50d | ||

| (R)-VAPOL | 10 | PMB | 86 | 54 | ||

|

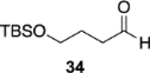

|

(S)-VAPOL | 5 | Bn | 85 | −91d |

| (S)-VANOL | 5 | Bn | 66 | −80d | ||

| (R)-VAPOL | 10 | Bn | 80 | 96 | ||

| (S)-VAPOL | 5 | PMB | 76f | −92d,f | ||

| (R)-VAPOL | 10 | PMB | 87g | −95g | ||

| (S)-VANOL | 5 | PMB | 63 | −83d | ||

|

|

(S)-VAPOL | 5 | Bn | 84 | −50d |

| (R)-VAPOL | 10 | Bn | 88 | 92 | ||

| (S)-VAPOL | 5 | PMB | 67 | −51d | ||

| (R)-VAPOL | 10 | PMB | 78 | 88 | ||

|

|

(S)-VAPOL | 5 | Bn | 75 | −76d |

| (R)-VAPOL | 10 | Bn | 74 | 96 | ||

| (R)-VANOL | 10 | Bn | 80 | −91d,h | ||

| (S)-VANOL | 10 | Bn | 99 | 95i | ||

Unless otherwise specified, all reactions were carried out in toluene at 0 °C for 12 h with 0.5 mmol diazo compound 1 at 0.1 M with 1.2 equiv of the aldehyde. The catalyst was prepared as indicated in Table 1.

Isolated yields.

Determined by HPLC.

The enantiomer of the epoxide is formed.

Reaction at −40 °C for 12 h.

Average of two runs.

Average of four runs.

This reaction was carried out with a boron catalyst as indicated in Scheme 3 in toluene at −40 °C for 12 h without DMSO.

Carried out as in h but with 20 mol % DMSO.