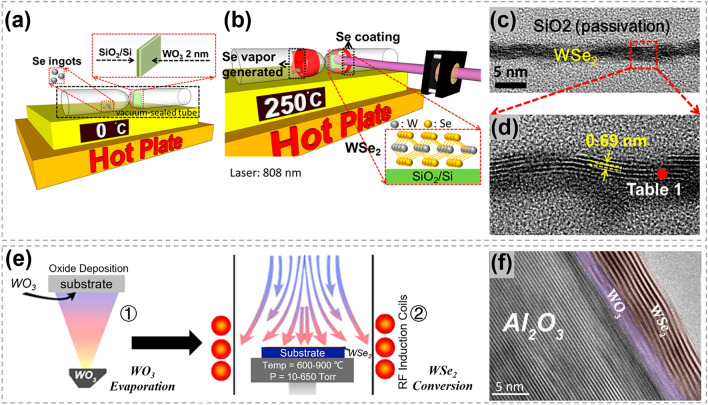

Fig. 19.

Synthesis of WSe2 by the oxygen-chalcogen exchange process. a Illustration showing 2 nm-thick WO3 on SiO2/Si and Se ingots was vacuum-sealed together. b Illustration showing the formation of WSe2 when heating up to 250 °C. c Across-sectional TEM image of WSe2. d HMTEM image revealing the interlayer distance of the WSe2. Reproduced with permission [160].

Copyright 2015, American Chemical Society. e Synthesis process of WSe2 converted from amorphous WO3 and hexagonal stabilized WO3 films. Thermal evaporated WO3 films were annealed via rapid thermal annealing and then converted to WSe2 via cold wall furnace. f TEM image of the obtained layered WSe2 structure and the unconverted WO3 film between sapphire and WSe2. Reproduced with permission [164]. Copyright 2015, IOP Publishing