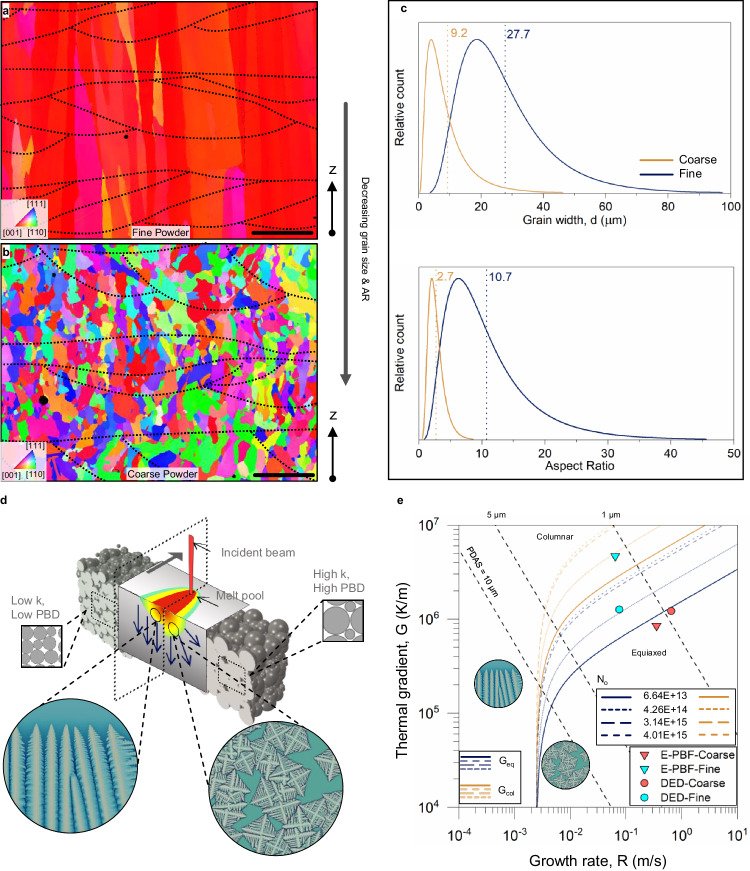

Fig. 5. Powder-size driven MPE applied to E-PBF process for a facile and large-scale grain control.

IPF-z maps obtained from EBSD of E-PBF fabricated (a) fine- and (b) coarse-powder samples. The scale bars in both (a) and (b) are 100 µm. c Quantitative analysis of grain size and shape obtained in the fine- and coarse-powder samples. d General schematic on the impact of coarse vs fine PSD on the melt pool shape and its microstructure. e Solidification maps with distinct columnar and equiaxed regions (demarcated by orange and blue boundaries, respectively). Four different values of nucleation density, No, of 6.64 × 1013, 4.26 × 1014, 3.14 × 1015, and 4.01 × 1015 are determined through experimental observations of equiaxed grain volume fractions obtained in the E-PBF-Fine, E-PBF-Coarse, L-DED-Fine, and L-DED-Coarse EBSD maps. PDAS stands for primary dendrite arm spacing.