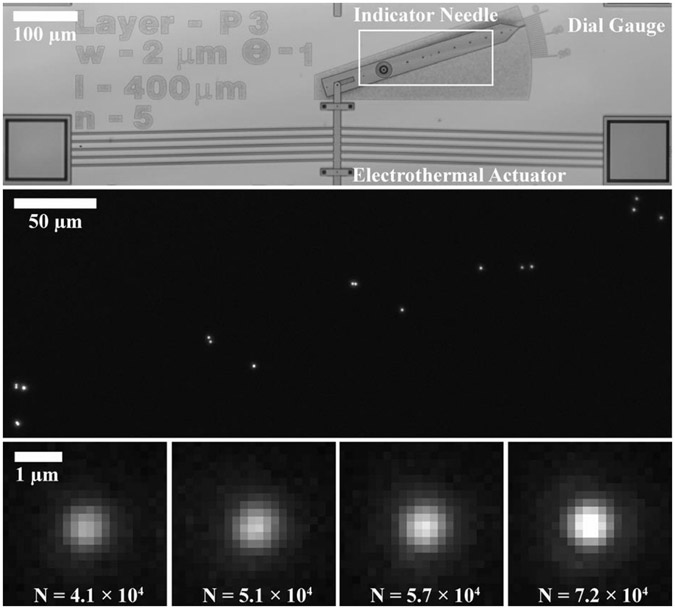

Fig. 2.

(Top) Optical brightfield micrograph showing a microelectromechanical system (MEMS) in the form of a goniometer, with an electrothermal actuator linked to an indicator needle. Linear actuation of the electrothermal actuator resulted in rotary motion of the indicator needle around a pivot. Coarse measurement of rotation was enabled by a graduated dial gauge. A region of interest is indicated by a white box. (Middle) Optical fluorescence micrograph showing a constellation of fluorescent nanoparticles on the indicator needle in the region of interest. (Bottom) Optical fluorescence micrographs showing four of the nanoparticles that label the indicator needle, appearing as the point spread function of the imaging system. The nanoparticles are ordered from left to right by increasing numbers of detected signal photons (), which vary due to polydispersity in nanoparticle size and heterogeneity in illumination intensity. A larger number of detected signal photons results in a lower measurement uncertainty, motivating weighting of the contributions of individual nanoparticles to the overall measurement.