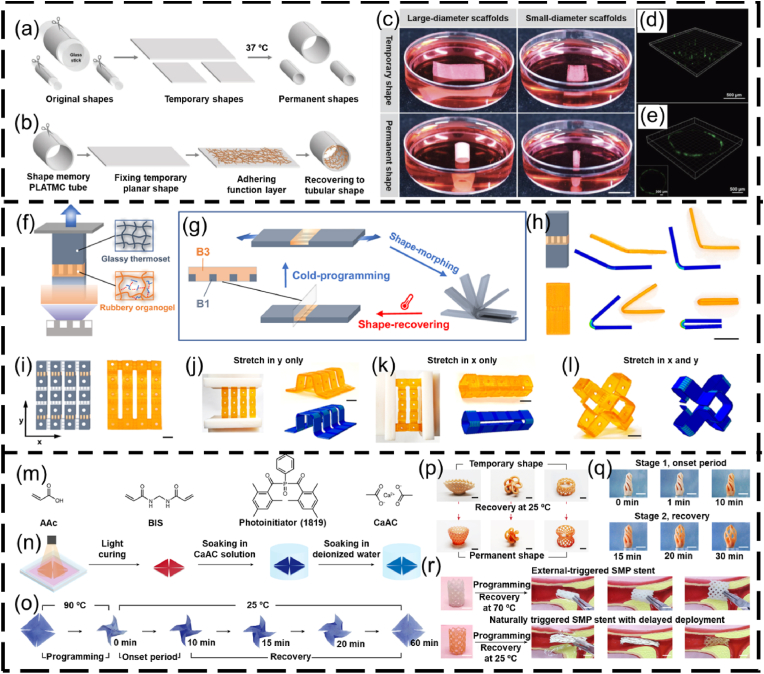

Fig. 4.

SMPs reshaping using heat programming, cold programming, and phase separation programming. (a–e) Heat programming of PDLLA-co-TMC: (a) reshaping PDLLA-co-TMC membranes into tubular structures, (b) attachment of a fibrous membrane with the PDLLA-co-TMC to form bilayer scaffolds, (c) photograph showing the self-tubing of bi-layer scaffolds (scale bar = 1 cm), (d, e) confocal images showing the cell distribution (d) before and (e) after deformation. Reproduced with permission [44]. Copyright 2018, Wiley-VCH. (f–l) Cold programming of shape-shifting structures via g-DLP: (f) schematic illustration of g-DLP to create multi-material objects combining B1 glassy thermoset and B3 rubbery organogel (B1 and B3 refer to two different photocuring resins), (g) schematic of the heterogeneous hinge module design and morphing, (h) bending degrees of the hinge under different strain forces, (i) g-DLP 4D-printed structures with the hinges, and (j–l) corresponding different deformed morphologies by applying (j) y-directional force, (k) x-directional force, and (l) dual x-y directional forces (scale bar = 1 cm). Reproduced with permission [107]. Licensed under a Creative Commons CC BY license. (m–r) Programming SMPs via phase separation: (m) monomer precursors of a 4D photocurable ink, (n) DLP-4D printing process of a windmill, (o) a shape-shifting process of the windmill under 25 °C including a programming step of the shape-morphing onset time at 90 °C, an onset period, and a shape recovery period at 25 °C, (p) different shape-morphing structures, (q) shape morphing with a controlled onset of 10 min at the ambient temperature of 25 °C, (r) a comparison of the deployment of SMP stents made of heat programming and phase separation (scale bar = 1 cm). BIS, N,N′-methylenebisacrylamide; AAc, acrylic acid; CaAc, calcium acetate [109]. Reproduced with permission [109]. Copyright 2023, Springer Nature.