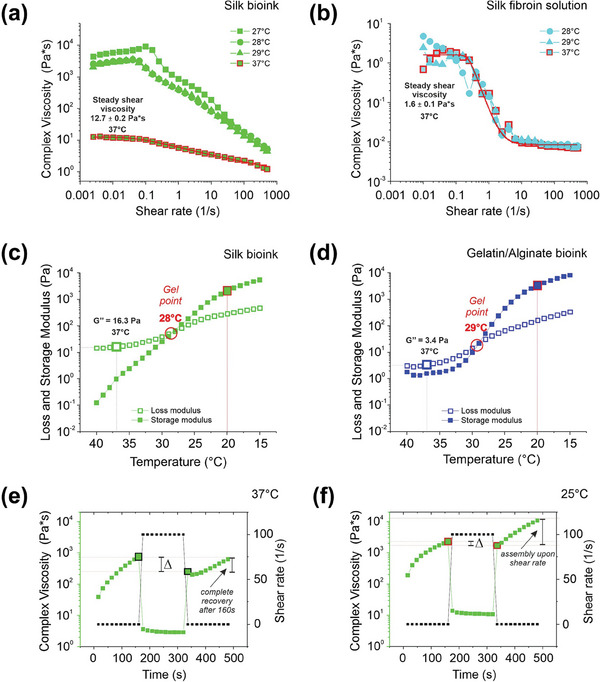

Figure 2.

Rheological characterization. a,b), Flow sweep was performed at different temperatures to evaluate the complex viscosity as a function of the shear rate of a), silk bioink, and b), silk fibroin solution. Red lines are the values of complex viscosity at 37 °C fitted with the Carreau–Yasuda model. Representative of three independent experiments. c,d), Temperature ramp tests showed the behavior of loss (G’’) and storage (G’) modulus as a function of temperature decrease from 40 to 15 °C of (c), silk bioink and (d), gelatin/alginate bioink. The crossover point (G’ = G’’) indicates the gel point (red circle). e,f), Thixotropic test was performed to monitor silk bioink complex viscosity during a deformation and a recovery phase at (e), 37 °C and (f), 25 C. The analysis was performed by applying an initial shear rate of 0.01 1 s−1 for 160 s, which was ramped up to 100 1 s−1 for 160 s (deformation phase) and finally ramped down to 0.01 1 s−1 (recovery phase). The Δ indicates the recovery step after the deformation process. Representative of three independent experiments.