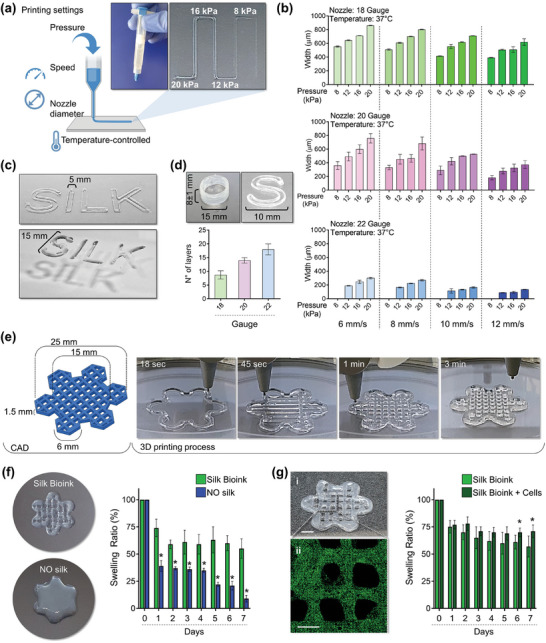

Figure 3.

Silk bioink printability. a), Printing pressure, speed, nozzle diameter, and temperature determine the resolution of a filament extrusion‐based 3D printer. Cartoon was made using BioRender.com b), The silk bioink can be 3D printed using needles of different diameters 18G (top, green), 20G (middle, pink), and 22G (bottom, blue), at various printing speeds (6,8,10,12 mm −1s) and pressures (8,12,16,20 kPa) (n = 3). c), The silk bioink can be extruded to obtain constructs of tailored widths and heights. d), 3D printing with a 20 G nozzle at 8–10 mm −1 s speed, with 12–16 kPa pneumatic pressure, ensure a good balance of print fidelity and accurate deposition to obtain 3D constructs having a height with stable junctions between the layers (n = 3). e), Model (left) of a layered grid hexagon intersecting smaller hexagons at its borders designed to model a “flower”‐like shape. The 3D printing process into a petri dish is shown (right). f), The presence of silk in the bioink formulation is crucial for ensuring printing fidelity when compared to the same formulation without silk (left). The analysis of silk bioink swelling ratio compared to bioink formulations without silk (NO silk) is shown (right) (n = 3, * p<0.01). g), Confocal microscopy analysis of HSPCs after bioprinting into the silk bioink (i: scale bar = 4 mm; ii: green = CD34; scale bar = 2 mm) (left). The analysis of silk bioink swelling ratio in the presence or absence of HSPCs is shown (n = 3, * p<0.05).