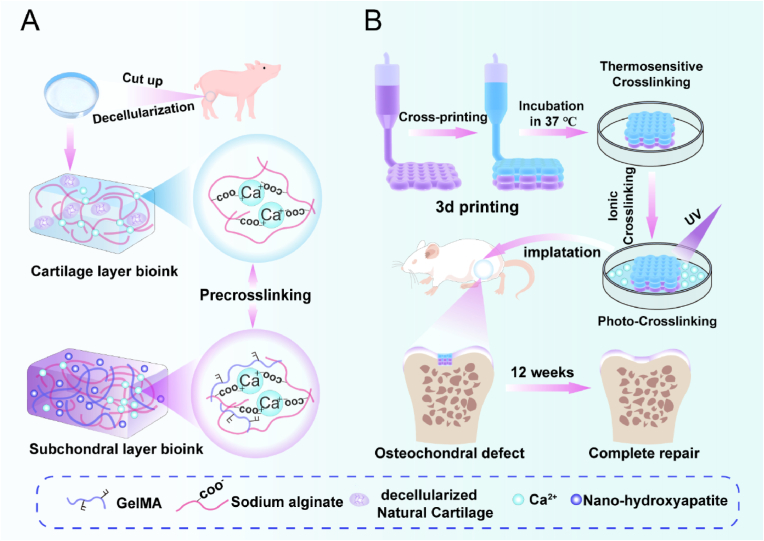

Fig. 1.

Schematic of bioink formulation and 3D bioprinting to create heterogeneous constructs to repair osteochondral defects. A) Cartilage layer bioink (blue) was formed by sodium alginate with certain Ca2+ and decellularized natural cartilage (dNC). The subchondral layer bioink (purple) was formed by sodium alginate with a certain amount of Ca2+, gelatin methacryloyl (GelMA), and nano-hydroxyapatite (nHA). B) Illustration of 3D printing biphasic constructs for osteochondral defect repair. Multiple crosslinking methods were employed in combination. This entailed initial low-concentration calcium ion pre-crosslinking, thermosensitive crosslinking, high-concentration Ca2+ second crosslinking, and finally, photocrosslinking. The transitional zone was constructed using a dual-nozzle cross-printing approach. The biphasic scaffold was transplanted into the osteochondral defect area of a rat for osteochondral regeneration.