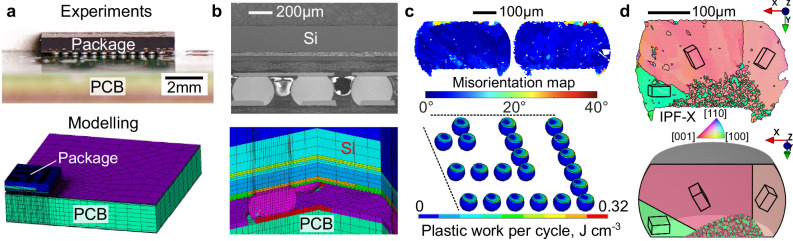

Fig. 1. Parallel thermal cycling experiments and modelling.

a 84CTBGA package soldered to a printed circuit board (PCB): photograph and quarter finite element model. b Micrograph and board-level finite element (FE) model of a cross-section through solder joints. c Damage accumulation in the solder near the package side after thermal cycling: experimental EBSD misorientation maps and accumulated plastic work per cycle from the board-level FE model. Displacement fields from the top and bottom of solder joints are then transferred from the board-level continuum model to the individual solder joint CPFE model. d Typical partially interlaced time-zero beachball microstructure from EBSD orientation mapping (Inverse Pole Figure IPF-X colour map) and 3D geometrical model input into the CPFE model.