Table 11.

Partial oxidation of alkyl aromatics utilizing O2 catalyzed by Si@Porp. Co&Cu.

| Entry | Alkyl Aromatics | Products | Conversion (%) | Selectivity (%) |

|---|---|---|---|---|

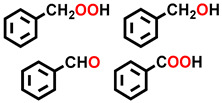

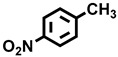

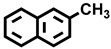

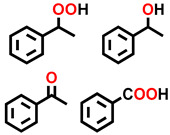

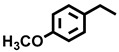

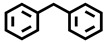

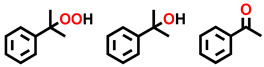

| 1 a |

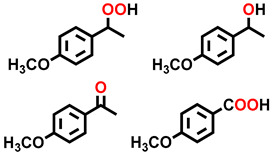

|

|

25.6 | 30.2, 5.6, 23.7, 40.5 |

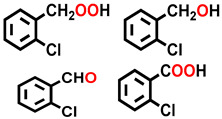

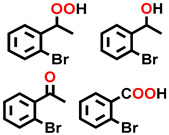

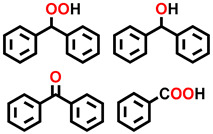

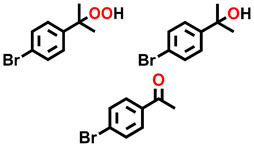

| 2 a |

|

|

12.9 | 36.4, 6.4, 15.3, 41.9 |

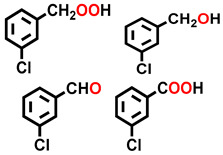

| 3 a |

|

|

20.3 | 37.3, 11.4, 19.7, 31.6 |

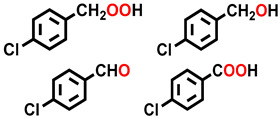

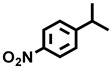

| 4 a |

|

|

39.0 | 27.2, 8.3, 25.5, 39.0 |

| 5 a |

|

|

21.2 | 29.4, 9.9, 20.1, 40.6 |

| 6 a |

|

|

37.1 | 32.6, 6.0, 18.6, 42.8 |

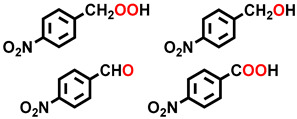

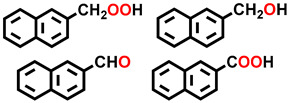

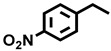

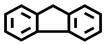

| 7 b |

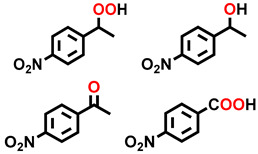

|

|

35.9 | 9.4, 29.6, 55.6, 5.4 |

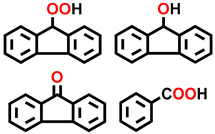

| 8 c |

|

|

26.7 | 7.8, 30.0, 51.9, 10.3 |

| 9 c |

|

|

45.1 | 6.0, 6.3, 85.3, 2.4 |

| 10 c |

|

|

30.2 | 5.3, 20.2, 72.6, 1.9 |

| 11 c |

|

|

40.2 | 8.8, 8.9, 77.6, 4.7 |

| 12 b |

|

|

25.7 | 6.8, 12.9, 76.3, 4.0 |

| 13 c |

|

|

36.2 | 3.3, 4.7, 89.0, 3.0 |

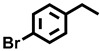

| 14 d |

|

|

43.3 | 87.1, 3.4, 9.5 |

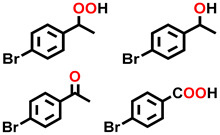

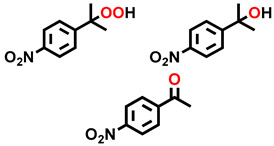

| 15 d |

|

|

37.8 | 85.1, 6.6, 8.3 |

| 16 d |

|

|

22.2 | 94.6, 1.5, 3.9 |

a Reaction conditions: substrate (alkyl aromatics, 50 mmol), O2 (1.0 MPa in constant supply), catalyst (Si@Porp. Co&Cu, 32 mg, 0.64 mg/mmol, NHPI, 10%, mol/mol), stirring at 600 rpm and 120 °C for 8.0 h. b Reaction conditions: substrate (alkyl aromatics, 100 mmol), O2 (1.0 MPa in constant supply), catalyst (Si@Porp. Co&Cu, 32 mg, 0.32 mg/mmol), stirring at 600 rpm and 140 °C for 8.0 h. c Reaction conditions: substrate (alkyl aromatics, 100 mmol), O2 (1.0 MPa in constant supply), catalyst (Si@Porp. Co&Cu, 32 mg, 0.32 mg/mmol), stirring at 600 rpm and 130 °C for 8.0 h. d Reaction conditions: substrate (alkyl aromatics, 50 mmol) in glass reaction tube, O2 (0.10 MPa in constant supply), catalyst (Si@Porp. Co&Cu, 32 mg, 0.64 mg/mmol), stirring at 600 rpm and 90 °C for 8.0 h.