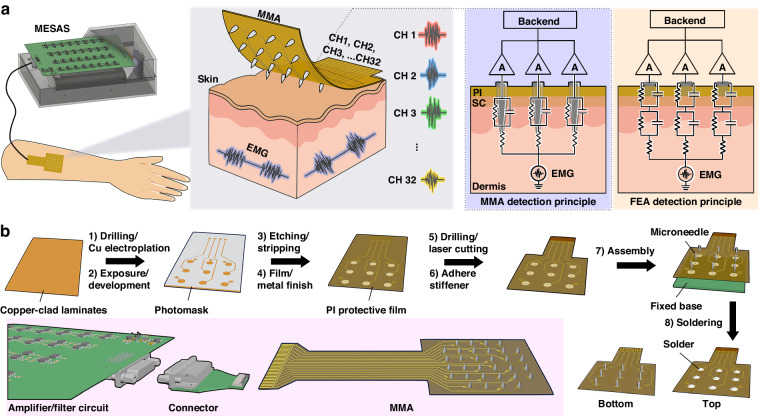

Fig. 1. Schematic diagram and fabrication process of the MMA for EMG signal detection.

a Schematic illustrating the use of the MMA sensor worn on the arm for real-time monitoring of EMG signals. A multichannel electrophysiological acquisition system (MESAS) was used to process the electrophysiological signals generated by the MMA, and the digital signals were ultimately transmitted to the computer for signal display. b Schematic diagram of the fabrication process of the MMA. A flexible printed circuit (FPC) process was utilized in which the copper foil substrate was initially cut into the desired pattern. Subsequently, holes were drilled and plated at the over-hole locations to achieve the desired configuration. Next, a photosensitive dry film was pressed onto the copper foil substrate and exposed, and a pattern of pad arrays, leads, etc., was formed through processing with a developing solution. The excess copper foil was etched away with an etching solution, and the dry film was peeled off to obtain the desired circuit pattern. The pads were chemically gold-plated to provide corrosion and oxidation resistance, and polyimide (PI) insulating material was employed to effectively insulate the leads. The prepared flexible circuit board was positioned on a rigid board (FR4 substrate), and the microneedles were inserted vertically. Finally, microneedles were soldered to the pads using solder, resulting in the final MMA sensor