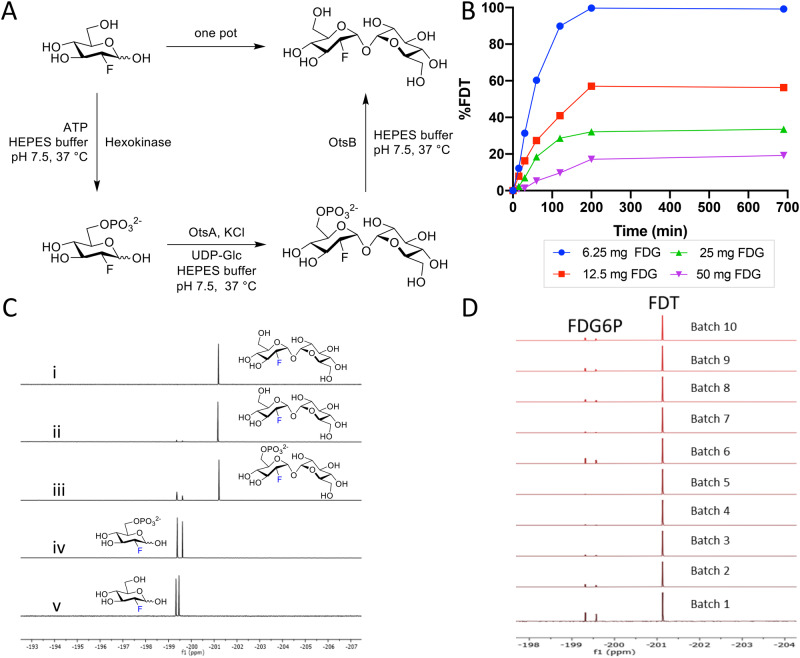

Fig. 2. Reaction Optimization, Scale-up and Batch Synthesis in the Development of an Efficient Scaleable One-Pot Synthesis.

A Chosen Route C (from Fig. 1) was tested in a one-pot format [19F]FDT using pyrogen-free enzymes OtsASf and OtsBSf. B Example reaction optimization with fixed donor sugar Glc-UDP [30 mM] at different acceptor substrate concentrations (9.08, 18.17, 36.34 and 72.68 mM) of [19F]FDG; reactions were monitored in real time by calibrated 19F NMR. Please also see Source Data File. C Direct reaction monitoring of the steps of one-pot, 3-step [19F]FDT synthesis from [19F]FDG by 19F-NMR. NMR spectra: (i) 19F NMR spectrum of purified [19F]FDT; (ii) Crude 19F NMR spectrum of [19F]FDT with small amount of deoxy-fluoro-G6P ([19F]-1) still present; (iii) Crude 19F NMR spectrum of intermediates [19F]-1 and [19F]-2; (iv) Crude 19F NMR spectrum of [19F]-1 from [19F]FDG conversion; and (v) reference sample of starting material [19F]FDG. D Representative, 19F-NMR spectra of crude reaction mixtures containing [19F]FDT from repeated batches using fresh enzyme (including from newly expressed preparations) and reactants synthesized by 3-enzymes-3-steps, one-pot syntheses, prior to purification.