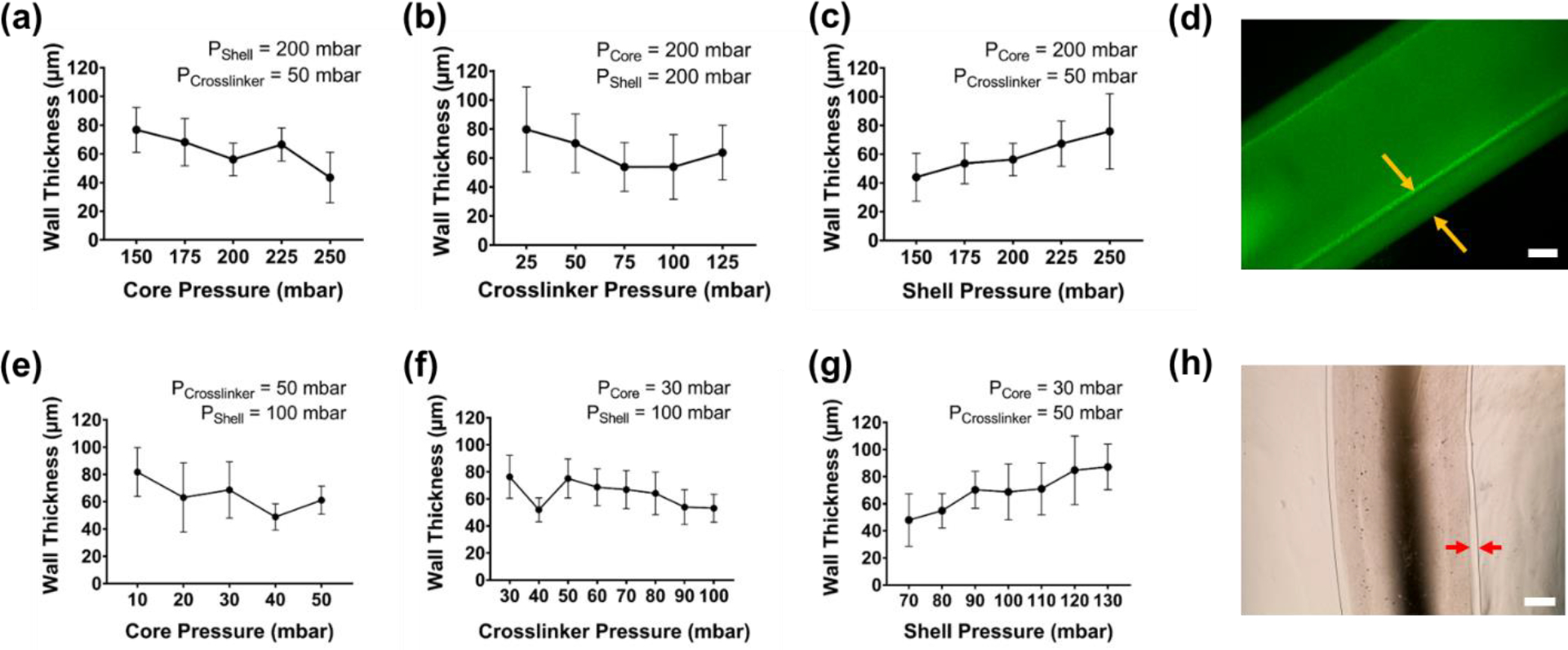

Figure 3. Shell pressure defines wall thickness for printed tubes.

In (a) to (d), open alginate tubes were printed using 6% PVA solution in the Core inlet, 1.5% alginate in the Shell inlet, and 125 mM calcium chloride solution in the Crosslinker inlet. As Core (a) and Crosslinker (b) pressures were varied, minimal changes were observed in the wall thickness, as measured by brightfield microscopy. (c) In contrast, wall thickness was adjustable as a function of Shell pressure and could be tuned from ~45–75 μm across pressure ranges of 150–250 mbar. (d) Fluorescence micrograph demonstrates a representative printed tube. Yellow arrows indicate the tube wall being measured. Scale bar = 100 μm. Similarly, in (e) to (h), open alginate tubes were printed using 0.006% PVA solution in the Core inlet, 1.5% alginate in the Shell inlet, and 125 mM calcium chloride solution in the Crosslinker inlet. As Core (e) and Crosslinker (f) pressures were varied, minimal changes were observed in the wall width, as measured by brightfield microscopy. (g) In contrast, wall width was adjustable as a function of Shell pressure and could be tuned from ~50–90 μm across pressure ranges of 70–120 mbar. (h) Brightfield image demonstrates a representative printed tube. Red arrows indicate the tube wall being measured. Scale bar = 500μm. Error bars indicate +/− standard deviation for n = 3 measures.