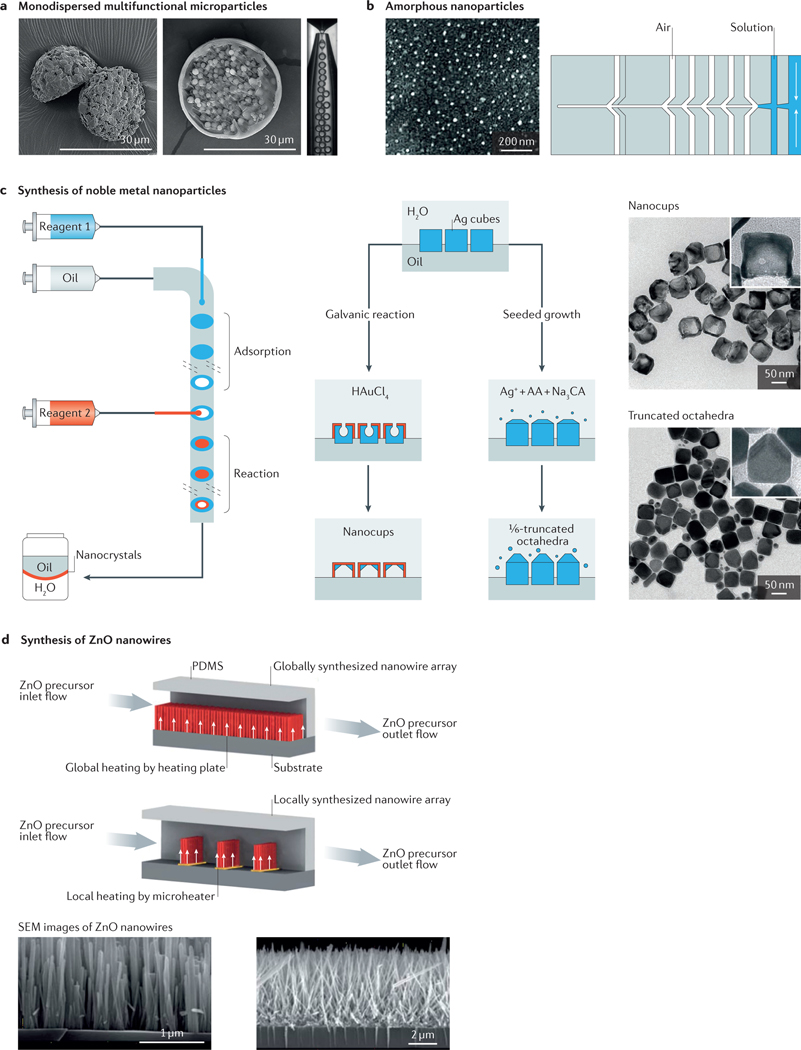

Figure 4 |. Fabrication of micro- and nanoparticles in microfluidic systems.

a | Microfluidic fabrication of monodispersed microparticles. The two scanning electron microscopy (SEM) images show the formation of Janus particles (left) and microcapsule particles (right). b | Amorphous nanoparticles prepared using a microfluidic nebulator (the example shown is for CaCO3 nanoparticles, although this method can be applied for a wide range of materials). c | Synthesis of noble metal nanoparticles (for example, Ag nanocubes, Ag truncated octahedra and Au–Ag nanocups) in microfluidic droplet reactors with multistep adsorption and reactions. Transmission electron microscope images of the particles are shown on the right. d | In situ synthesis of ZnO nanowires in a microfluidic chip; comparison of global synthesis in the entire fluidic channel and local synthesis by microheaters in the fluidic channel. SEM images of the nanowires are shown below. AA, ascorbic acid; CA, citric acid; PDMS, polydimethylsiloxane. Panel a is adapted with permission from REF. 98, Royal Society of Chemistry. Panel b is adapted with permission from REF. 117, AAAS. Panel c is adapted with permission from REF. 125, American Chemical Society. Panel d is adapted with permission from REF. 127, Royal Society of Chemistry.