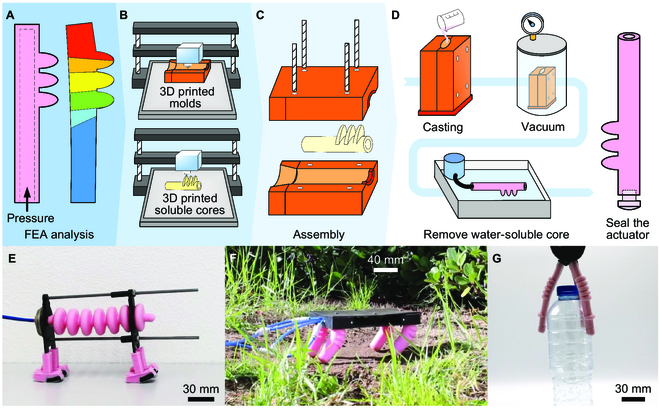

Fig. 1.

Design fabrication of soft robot actuators in a single casting step. (A) FEA-based numerical simulation to optimize the actuator’s geometry and actuation parameters. (B) Using FFF technology, the molds are printed in rigid material and the sacrificial cores in a water-soluble material. (C) Molds and core are assembled following a standard molding process. (D) The elastomer in the liquid state is poured into the molds, followed by a period in the vacuum chamber to remove air bubbles. Once the elastomer is cured and extracted from the molds, the heated water circuit is used to dissolve the sacrificial water-soluble cores, and finally, the actuator is sealed. (E) Earthworm-inspired robot composed of a single linear actuator. (F) Four-legged robot moving on a flat garden surface. (G) A soft pneumatic gripper grasping a plastic water bottle. All robots are pneumatically actuated.