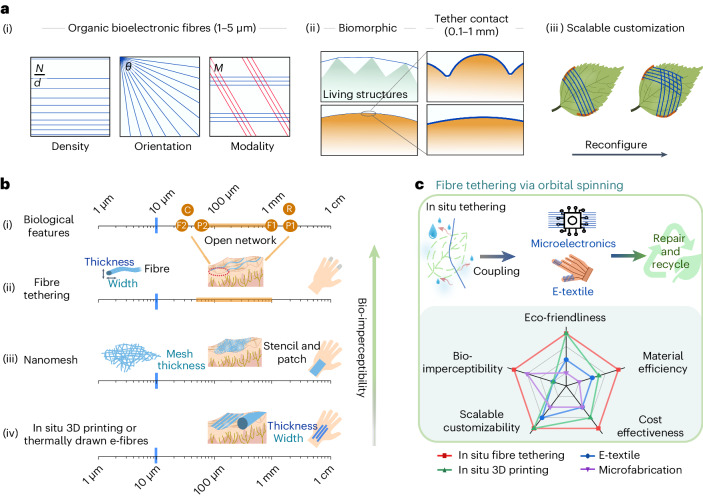

Fig. 1. Imperceptibly augmented living structures with organic bioelectronic fibres.

a, (i) Fibre number density (number of fibres (N) over the width of the fibre array (d)), fibre orientation (θ) and modalities (fibre materials and pattern design) can be customized during in situ fibre tethering; (ii) intimate contacts are achieved between the organic bioelectronic fibres (each around 1–5 µm wide) and different biological surfaces with micro- to millimetre-scaled topographies and (iii) the bioelectronic fibre arrays are reconfigurable to support scalable customization of electronic and sensing elements on living structures in situ. b, Length scales and/or feature sizes are indicated for (i) biological structures on the human skin of a hand, including sweat pores (density around 250–500 per cm2, symbol P1; pore size around 60–80 µm, symbol P2, ref. 55), fingerprint ridges (millimetre ridge-to-ridge spacing, symbol F1 and ridge height of around 20–40 µm, symbol F2, ref. 56), single skin cells (sizes around 30 µm, symbol C57) and receptor fields on the fingertip (around the millimetre range, symbol R58); (ii) bioelectronic fibre tethering for its fibre width, thickness and network opening; (iii) nanomesh for its mesh thickness and mesh opening2,5,21 and (iv) in situ printing or thermally drawn e-fibres for their line (or fibre) width and thickness6,31. A network or mesh of fibres is considered as fully skin imperceptible if it simultaneously fulfils the conditions of: (1) network or mesh opening between fibres greater than around 50 µm (the sweat gland pore size), but smaller than 1 mm (the fingertip receptor field); (2) width of individual fibres and thickness of the network or mesh smaller than around 10 µm (such that individual skin cells are mostly exposed through the open fibre network, and the fingerprint ridge features are not compromised). c, In situ fibre tethering can be used to couple prefabricated microelectronics and electronic textiles, while supporting on-demand device repair, upgrade and recycle. Multi-faceted key performance indicators are compared for different methods for fabricating fibre-like building blocks, where the scales of 1–4 are assigned as 4 = excellent, 3 = very good, 2 = acceptable and 1 = needing improvement. The scores are assigned considering the literature4–6,9,10,13,17,18,30,31,37, and discussion in Supplementary Notes 7 and 8 and Supplementary Table 1.