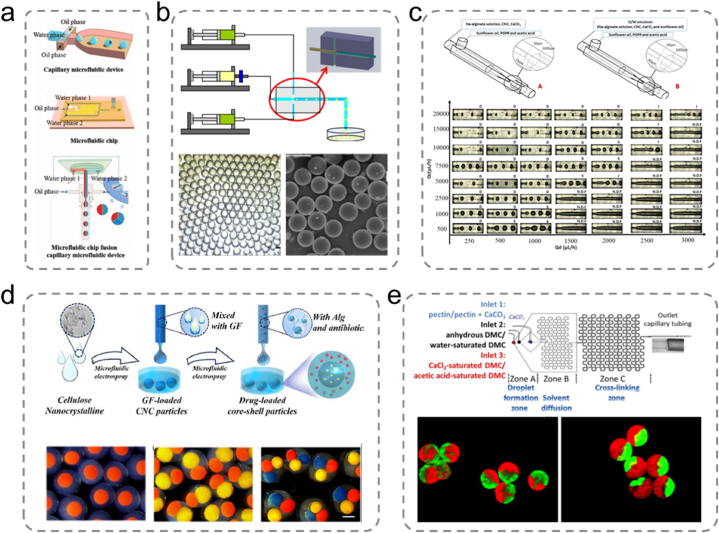

Fig. 8.

(a) Devices used for the preparation of microfluidic hydrogel microspheres [28]. Adapted reprinted with permission from Ref. [28], License Number: 5,792,500,948,298. Copyright © 2021 Wiley‐VCH GmbH. (b) Schematic of the coaxial microfluidic device for the preparation of chitosan (CS) microspheres and optical and scanning electron micrographs of CS microspheres [121]. Adapted reprinted with permission from Ref. [121], License Number: 5,792,510,975,707. Copyright © 2012 Elsevier B.V. All rights reserved. (c) Schematic of a co-flow glass microfluidic device for the production of alginate microspheres and the process of droplet formation under different continuous and dispersed flow rate conditions [122]. Adapted reprinted with permission from Ref. [122], License Number: 5,792,520,088,612. Copyright © 2021 Elsevier Ltd. All rights reserved. (d) Generation of multicompartmental core-shell particles consisting of cellulose nanocrystals and alginate containing growth factors and antibiotics, respectively. Optical microscopy images of monodisperse multicompartmental core-shell particles with one, two, and three nuclei [123]. Adapted reprinted with permission from Ref. [123], License Number: 5,792,530,184,633. Copyright © 2021 Elsevier Ltd. All rights reserved. (e) Schematic of a microfluidic flow focusing chip for pectin hydrogel microparticle formation. Fluorescence image of Janus hydrogel microparticles [124]. Adapted reprinted with permission from Ref. [124], License Number: 5,792,530,968,511. Copyright © 2014 Elsevier Ltd. All rights reserved.