Figure 2.

Production and application of microfabricated bioelectronic fibers

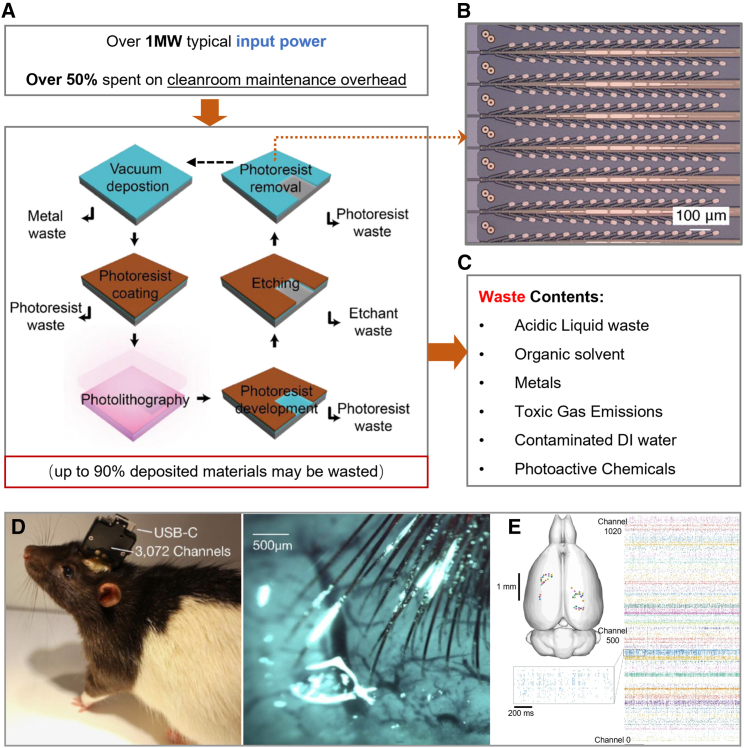

(A) Input power allocation of a typical cleanroom (top),39 with an example of a typical lithography-assisted subtractive process, sources of generated wastes40 (middle flow chart) and the possible range of material wastage41 (bottom), reproduced with permission.40 Copyright 2020, Sui and Zorman.

(B) Photo of a batch of microfabricated fiber-shaped implant electrodes with multiple electrode pixels per fiber, reproduced with permission.32 Copyright 2019, Elon Musk, Neuralink.

(C) A non-exhaustive list of waste types that could originate from an active cleanroom.42,43

(D) A rat chronically implanted with the fiber electrodes in (B) as parts of a packaged implant device (left) and a perioperative photo showing the implanted flexible fiber electrodes inserted into the brain tissue (right). Reproduced with permission.32 Copyright 2019, Elon Musk, Neuralink.

(E) Example of implant insertion location marked on the rat brain (top) and raster plot from the electrical activities recorded from the channels on multiple implanted fiber electrodes (right). Raster plots are recorded electrical spike/events against time, which can reach millisecond-level time resolution (inset). Reproduced with permission.32 Copyright 2019, Elon Musk, Neuralink.