Figure 3.

Examples of additively manufacturing bioelectronics

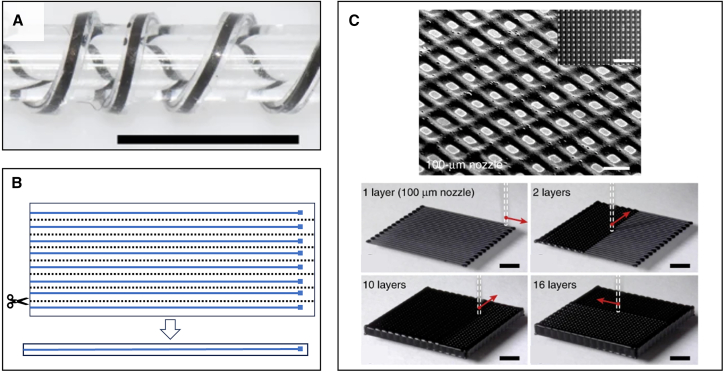

(A) A planar inkjet-printed flexible bioelectronic fiber on silicone backbone with sub-millimeter width, as a neuromuscular implant electrode (scale bar, 4 mm). Adapted with permission.46 Copyright 2020, Springer Nature.

(B) Example schematic of separately processing the substrate of an inkjet-printed fiber: separating a fiber-shaped device from a planar inkjet-printed sheet, i.e., “print and cut.” Blue color marks bioelectronic material ink; a dashed line marks designed cutting locations.

(C) A 3D resin printing product with complex merged internal structures. The top view shows a microscopy image of its indivisibly merged internal structures (scale bar, 200 μm; inset scale bar, 1 mm), and the bottom photos show the stacking structure formation using layer-by-layer 3D resin printing (scale bars, 2 mm). Adapted with permission.47 Copyright 2020, Yuk et al.