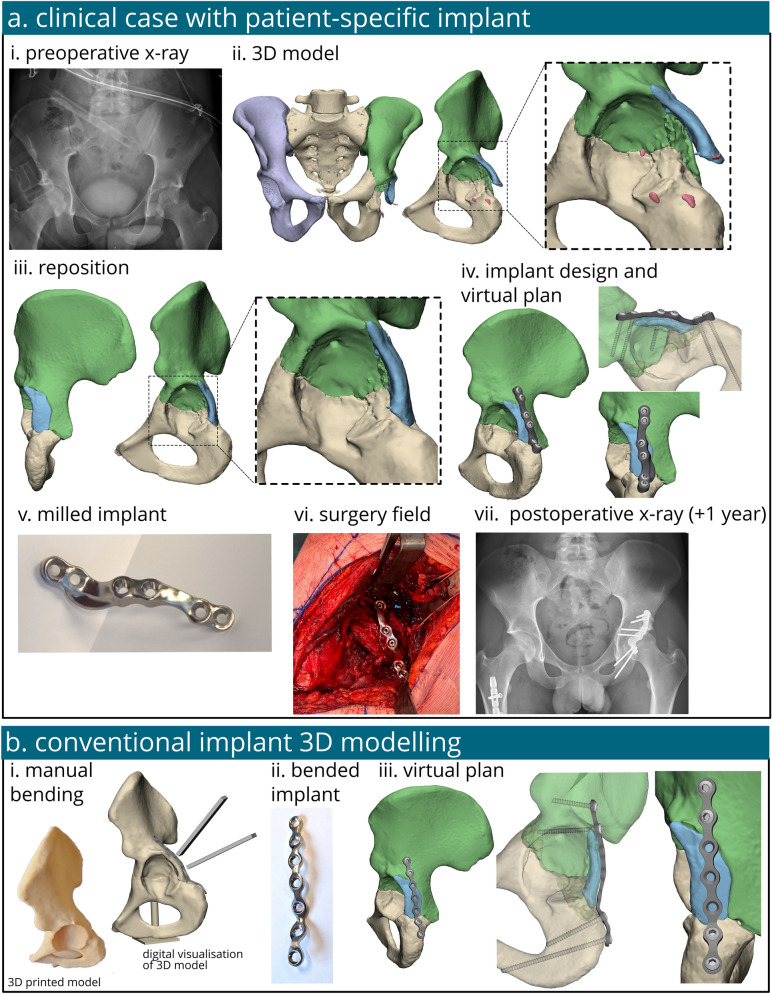

Fig. 1.

The workflow of the treatment and analysis of a patient with an acetabular fracture treated with either a patient-specific implant or a conventional off-the-shelf implant. The case taken for the computational analysis was those of a patient treated in our institution for an acetabular fracture surgically managed with a patient-specific implant. The process started with an x-ray (a-i) followed by 3D modelling and bone segmentation of the CT scan (a-ii) and repositioning of the bone fragments (a-iii). A patient-specific implant was created (a-iv), milled out of titanium (a-v) and placed during surgery (a-vi). At one year follow-up the x-ray showed good clinical results (a-vi). The conventional implant was also 3D modelled for comparison, it was manually bended on a 3D printed model (b-i), scanned (b-ii) and virtually placed in 3D (b-iii)