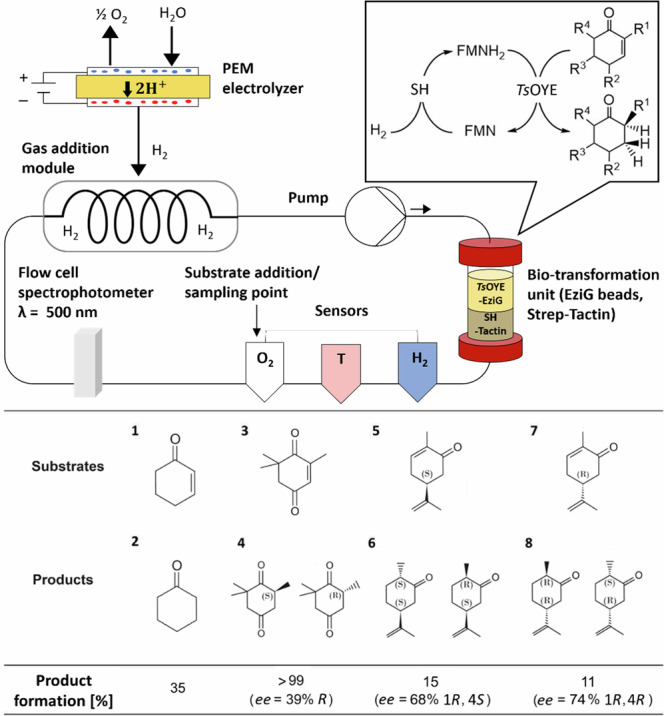

Fig. 1. Platform for electro-driven FMNH2-dependent asymmetric reduction of cyclic enones.

H2 is produced from a PEM electrolyzer using PtB/PtC as hydrogen evolution catalyst. A gas permeable tubing (PVMS or Teflon) transfers the H2 from the gas addition module to the flow system (17 mL, flow rate 2.6 mL min−1). H2 was supplied during biocatalysis to the gas addition module from the PEM electrolyzer (H2 10 mL min−1, 3.4 V, 0.89 A). Clark-type sensors for H2, optical sensors for O2, and temperature sensors and spectrophotometer (FMN) were integrated into the flow system to monitor online the interplay between enzymes and the electrolyzer. Due to overlapping of the substrates and FMNH2 absorbance peak, wavelength of 500 nm was used for FMN detection. The enzymes SH, and TsOYE were immobilized by Strep-Tactin XT 4Flow (down) and EziG beads (up), respectively, and packed into a column within the flow system. Reaction conditions: 17 mL, 50 mM Tris-HCl pH 8 at 20 °C containing SH (5 mg), TsOYE (6.5 mg), FMN (1 mM), catalase (5 mg) substrate 1 and 3 (25 mM), substrate 5 and 7 (5 mM). DMF as a cosolvent was added with the substrate at the ratio of 1:2. Conversions and ee values were determined by GC-FID. The flow system was at room temperature and the column with immobilized biocatalysts in temperature-controlled chamber was set at 30 °C. For upscale reaction, 3 was used at 18.5 mM concentrations.