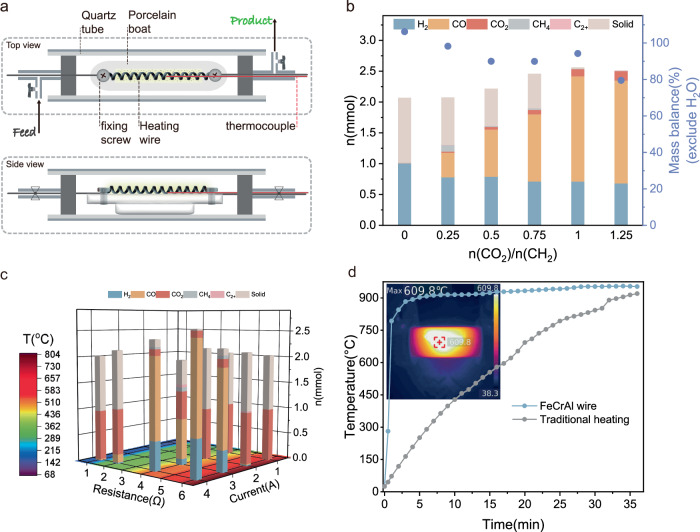

Fig. 1. Reactor configuration and reaction conditions screening.

a Schematic of an electrified reactor for CO2 reforming of plastics; b products distribution with different mole ratio of CO2 to CH2 in PE (n(CO2)/n(CH2)), Reaction conditions: PE = 14 mg, FeCrAl heating wire 6 Ω, current 4 A, T = 800 °C, 15 min; c the product distribution over temperature profile under different current and resistance values; Reaction conditions: PE = 14 mg, n(CO2)/n(CH2) = 1, FeCrAl heating wire, 15 min. the temperatures were measured by a thermocouple; d the heating rates of electrified FeCrAl heating wire (power = 96 W) and traditional tube furnace (power = 1000 W), the temperatures for the profiles were measured by a thermocouple, the inserted thermal image was recorded by a thermal camera (UTi-260B).