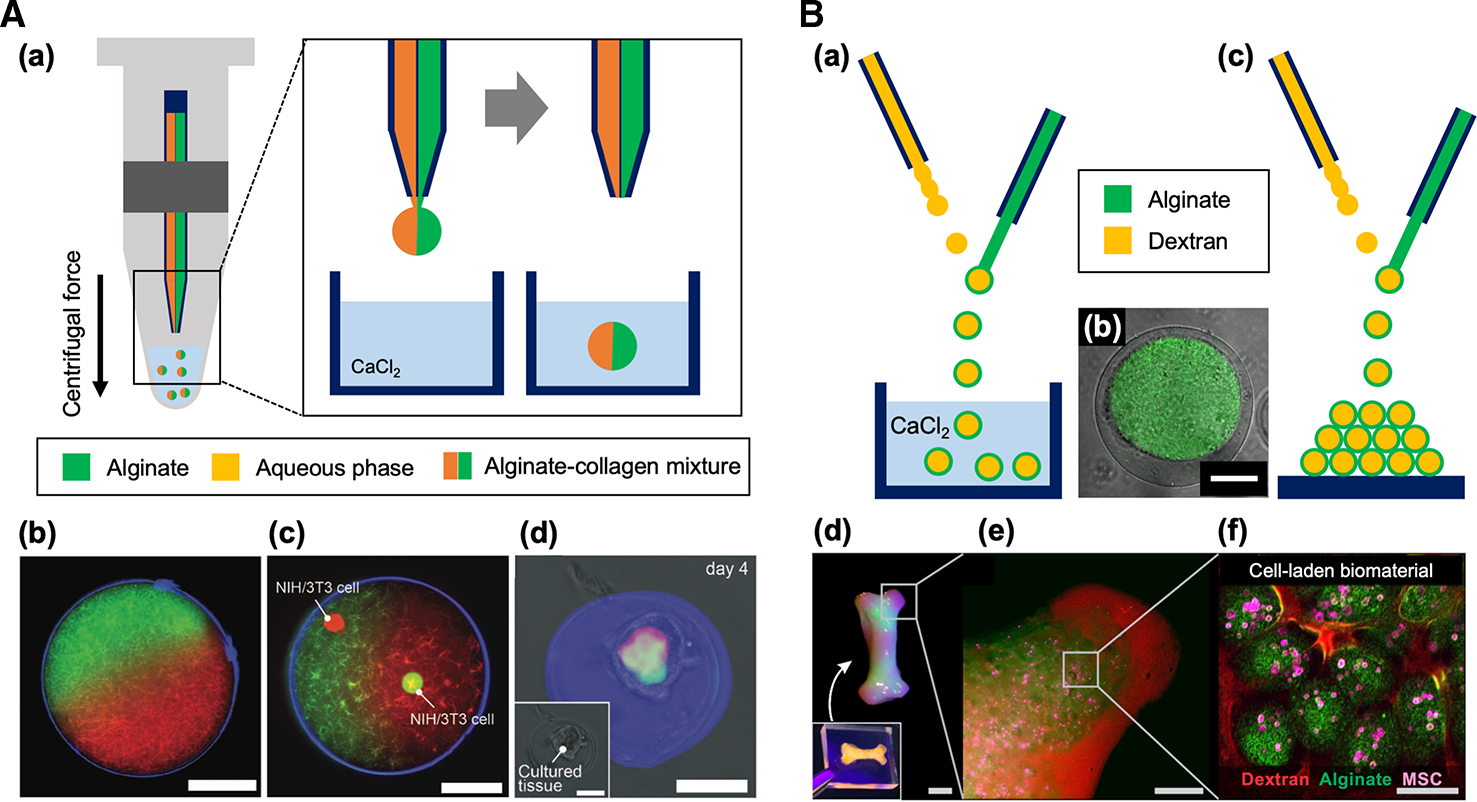

Figure 5. Non-chip-based high throughput microfluidics for cell-laden microparticle generation.

(A) (a) Schematic of a centrifuge-based microfluidic device for Janus microparticles. Anisotropic collagen microparticles (b) without and (c) with NIH/3T3 cells encapsulation. (d) Construction of microtissue in the microparticles after 4 days of culture. Scale bars: 50 μm. Reproduced with permission from ref. [56]. Copyright © 2017 John Wiley and Sons.

(B) (a) Schematic of in-air microfluidic (IAMF) device for core-shell microparticle generation. (b) Representative image of the dextran-tyramine-alginate core-shell microparticle. In this image, the core region (dextran-tyramine) can be distinguished with green color, while the shell region (alginate) is not labeled. Scale bar: 50 μm. (c, d, e & f) 3D printing application of IAMF. The 3D multiscale modular material was composed of human MSCs (mesenchymal stem cells, pink), which were incorporated in alginate microparticles (green) that are placed in dextran-tyramine hydrogel (red). Scale bars: 1 cm (d), 5 mm (e), 100 μm (f). Reproduced with permission from ref. [57]. Copyright © 2018 American Association for the Advancement of Science.