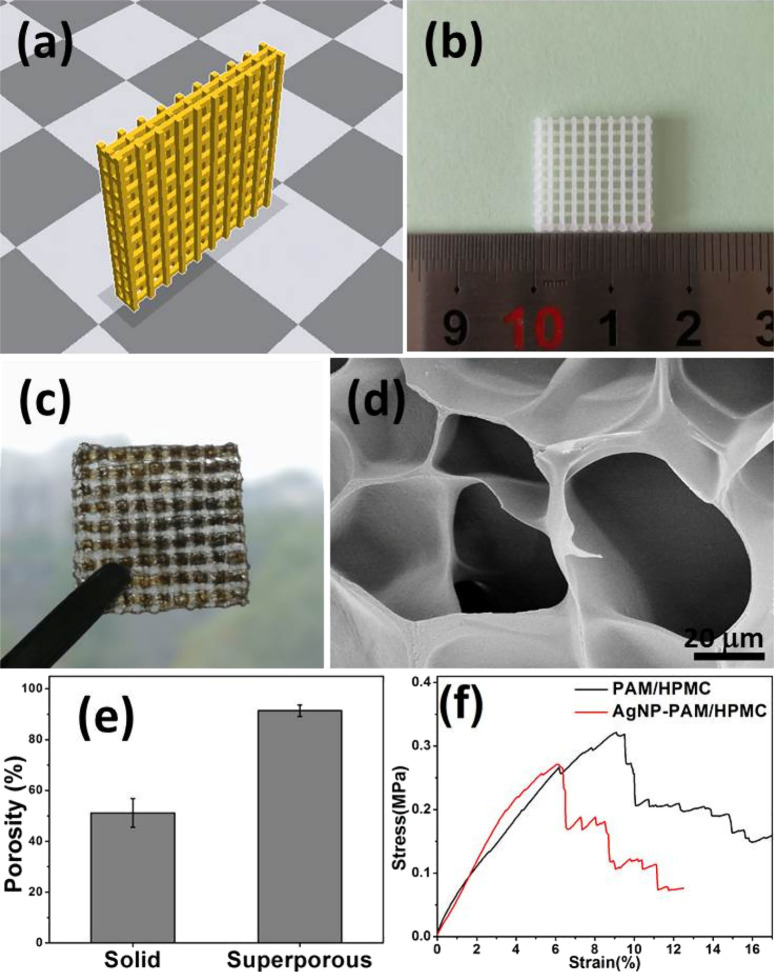

Figure 2.

Various stages and analyses of the development of a porous biomedical dressing. (a) The designed prototype is depicted as a 3D model of a yellow, grid-like structure intended for use as a template in creating biomedical dressings. (b) The printed PLA (poly(lactic acid)) template, shown alongside a ruler, has dimensions of 15 × 15 × 3 mm, with pore sizes of 1.2 × 1.2 × 0.8 mm and PLA wire diameters of 0.8 × 0.8 × 0.8 mm. This physical template is fabricated based on the initial 3D design. (c) Superporous AgNP-PAM/HPMC hydrogel dressings, derived from the PLA template, are illustrated being held by tweezers, emphasizing their high porosity aimed at enhancing biomedical application performance. (d) The SEM (scanning electron microscope) image offers a detailed view of the intricate porous structure of the superporous hydrogel dressing. (e) A bar graph compares the porosity levels of solid and superporous AgNP-PAM/HPMC hydrogels, revealing higher porosity in the superporous variants. (f) The stress–strain graph illustrates the mechanical properties of the superporous PAM/HPMC and AgNP-PAM/HPMC hydrogel dressings, showing that AgNP-PAM/HPMC demonstrates greater stress resistance at similar strains compared to PAM/HPMC. This figure is adapted with permission from the American Chemical Society.69,152