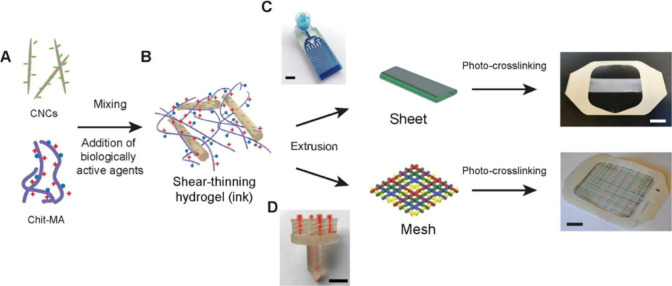

Figure 4.

Process of creating multifunctional wound dressings using cellulose nanocrystals (CNCs), chitosan methacrylamide (Chit-MA), and biologically active ingredients. Part (A) depicts the initial mixing of CNCs, Chit-MA, and biologically active substances such as proteins, small molecules, or nanoparticles. In the diagram, blue dots represent methacrylamide groups; red plus signs indicate positive charges; and green minus signs denote negative charges. Part (B) shows the formation of a shear-thinning hydrogel ink from this mixture, characterized by its solid-like behavior under low stress and liquidlike flow under high stress, suitable for extrusion-based 3D printing. Part (C) describes the extrusion of the hydrogel ink through a microfluidic printhead to fabricate sheets on a Tegaderm backing layer, followed by UV irradiation to initiate cross-linking and stabilize the hydrogel structure, with a scale bar indicating a thickness of 6 mm. Finally, part (D) details the extrusion process for creating multifunctional wound dressings on a Tegaderm backing layer, with subsequent UV exposure for cross-linking, and a scale bar indicating 1 cm. The use of food dyes demonstrates the capability to print filaments loaded with distinct active ingredients. This figure is adapted with permission from the American Chemical Society.64